Articles

If I Only Had a Waterjet Machine!

A waterjet machine would have made short, more-accurate work of Derek’s Chevy door panels.

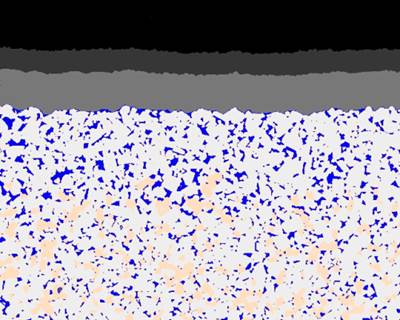

Read MoreAtomic-Level Coating Manipulation Adds Durability

Seco's Duratomic-grade inserts are said to run faster and longer than competitive models. Key to their performance is a unique texture achieved by manipulating the coating at the atomic level.

Read MoreApril Machine Tool Sales Show Accelerating Growth

According to USMTC, machine tool sales in April were 48% (units) and 123% (dollars) more than in April 2009.

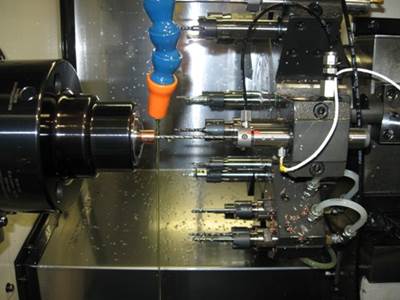

Read MoreDrilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

WatchWhat It Takes for Oilfield Success

Hunt and Hunt’s president says adopting turn/mill machines was one of the most challenging endeavors his 55-year-old shop ever undertook. He also says it’s the best thing the shop could have done to become more efficient at contract work.

Read MoreTaking on Titanium

The challenge for the aerospace machine shop is to produce titanium parts productively and profitably. The challenge for the machine tool builder is to help such shops meet this challenge.

Read MoreMachining Titanium for Today’s Advanced Aircraft

Several Global Titanium Day attendees were chosen to take flight in a reproduction of the Wright Brothers Model B Military Flyer.

Read MoreExceeding My Expectations

Here is a close-up of the precision machined parts floating in the barrel of a pen.

Read MoreShops Finding a Role for Additive Manufacturing

This metal assembly was made by Mark Two’s innovative rapid manufacturing process.

Read MoreIn-Country Outsourcing

Art Whelan is a senior vice president with Logistics Plus of Erie, Pennsylvania.

Read More