“Intelligent” CAM System Adapts to the Job

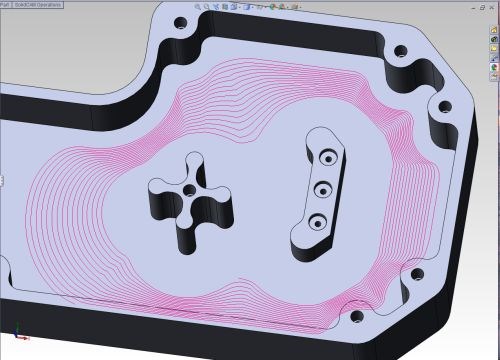

SolidCAM’s iMachining CAM software features an algorithm designed to eliminate potentially time-consuming, trial-and-error approaches to optimizing cutting parameters.

Share

These potentially time-consuming, trial-and-error adjustments happen every day in shops of all types and sizes—a fact not lost on SolidCAM when it developed its iMachining CAM system. This software is designed not only to provide effective tool paths, but also to enable users to efficiently apply those toolpaths according to their own particular preferences and application circumstances. Read this article to find out how.

Related Content

-

Addressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

-

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

-

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

.jpg;maxWidth=300;quality=90)