Share

Jeremy Taylor is the founder of Defiant CNC, a company that produces custom ERP systems. The business also includes a small machine shop, where Taylor tests and proves out his ERP product.

There are as many ways to run a machine shop as there are machine shops. Jeremy Taylor understands this well — not only has he worked in several machine shops, but he has also made custom ERP systems for more than 40 businesses, many of which are involved some form of manufacturing. Along the way, he’s learned a lot about the different ways shops can operate. “When I talk to a machining customer, no two shops are the same,” he says. “Their processes are different, the number of employees that they have, the types of machines, the type of manufacturing they do could all be different.”

Taylor is the founder of Defiant CNC, which produces custom ERP solutions for a range of industries, including education, consulting, construction, plumbers and electricians. About half of his customers, though, are manufacturers. He knows this market well because it was his gateway into the ERP business. Taylor started his manufacturing career while still in high school, working in a tool and die shop. After graduation, he started a tool and die apprenticeship through the Department of Workforce Development in Wisconsin. However, he fell in with the wrong crowd, as he recounts it, and when he was about six months from completing the requirements of the apprenticeship, he found himself facing a 14-year prison sentence.

During his incarceration, he kept up with machining trends and technology, while expanding his skill set, including learning different programming languages. “Since I did a lot of G-code programming for machining, I took to learning other programming aspects like Visual Basic for applications and JavaScript,” he says.

Go with the Workflow

Taylor developed his first ERP system while working at a machine shop. He grew frustrated with the system of folders inside folders that was used to track workflow, and got approval from his boss to build his own system for the shop.

After his release, Taylor moved to Orlando and started working in a machine shop. But he grew frustrated with the shop’s lack of ERP system. “The way that the company was keeping track of workflow was very primitive,” he explains. The shop used a system of folders inside folders, where important manufacturing data like prints and travelers were stored. “We’d have to dig down into four or five different folders in order to actually access the information that you need,” he adds. “That was just very inefficient.” Furthermore, the shop didn’t have a system for documenting part production processes. At best, things were written down on scraps of paper next to the machine. “That didn’t help if you were going to remake the same part six months later,” he says.

As Taylor spoke with people at other small shops, he realized these were common issues. These shops weren’t ready to invest in an off-the-shelf ERP program, but could benefit from a system that’s more efficient than folders within folders and scraps of paper next to a machine tool.

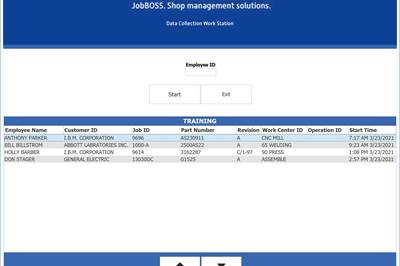

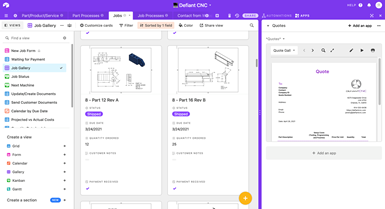

The ERP system is built on Airtable’s cloud-based relational databases. Airtable offers different ways to view data (including spreadsheets and calendars), forms to submit information, and integration with other apps like Google Docs.

It was around this time that Taylor’s sister introduced him to Airtable. Airtable is a cloud-based platform for relational databases that’s designed to be low-code and user-friendly. As he looked into it, he realized that he could use it to build an ERP system for the shop. What sets Airtable apart from other relational databases he was familiar with, such as Sharepoint and Microsoft Access, is that it’s much more accessible. “This is not intimidating to use, which is beneficial in a machine shop environment,” he notes.

He brought the idea to his boss at the shop, who gave him the green light to start building the system, which he worked on at home after working in the shop during the day. As he was building it out, he talked about it with his coworkers and incorporated their feedback into the system.

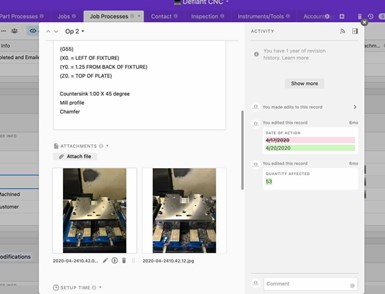

The new ERP system gave the shop a way to improve scheduling and track job status. It also helped save time—automated document creation saved time on administrative tasks, and having more complete and accurate part data (including CAM files, G-code, setup documents, and tool and fixture data) helped reduce setup times, Taylor says. Airtable’s product data management feature facilitates the organization, storage and retrieval of this information. This made it much easier and faster for the shop to re-quote parts it had made before and run them again. And storing this data indefinitely helped the shop track KPIs in the long term, and see where it could make improvements in different parts of the business.

Having an ERP system also improved internal communication. Employees throughout the organization (administrators, shop management, machinists, QC personnel and others) can tag one another in the system to leave notes, comments, photos, videos and other instructions about specific parts and processes. “No more illegible post-it notes around the shop that could get lost,” Taylor says.

This improved communication extended beyond the shop to external customers via a customer portal that enables them to track their parts as they move through the production process, as well as see all of the previous parts the shop has made and what parts, if any, the shop is holding for the customer in inventory. Before, Taylor says, whenever a customer inquired about parts in inventory, someone had to physically count them and figure out their status (for example, whether they needed to be cleaned, heat treated, deburred, plated, etc.).

As time went on, Taylor refined and improved the system. Many of the updates he made were based on new features Airtable released, which Taylor says happens regularly. These include new ways to view data, such as grid views (which display data similar to an Excel document), cards, a gallery view, calendars and forms to submit information. Airtable will also release new apps, including one that enables users to add JavaScript to run code. And new integrations help expand the system’s functionality. For example, Airtable can be integrated with Google Docs, enabling users to create a template form within Google Docs that Airtable can grab and fill out with relevant information. The doc can then be emailed to a customer, uploaded to Airtable or saved in Google Drive. In fact, a whole ecosystem of other companies that facilitate the use of Airtable has sprung up, such as Zapier, which helps with integrations.

A Customized Approach

Taylor customizes each ERP system based on the customer’s needs, and can add or remove functionality as a shop grows. For example, if a shop doesn’t have a CMM, it might need its ERP system to create inspection documents. But if the shop adds a CMM, it can remove this feature.

Eventually, Taylor started his own company, Defiant CNC, to begin offering custom ERP systems to other shops. “My area of focus is people who want something that isn't right out of the box, and where the ERP system isn't assumed to fit their needs,” he explains. “It's very customizable, very modular.”

For example, if a shop doesn’t have a CMM, it might want its ERP to include programs that help automate the recording of part dimensions and document creation for first article inspections or certificates of conformance. But if a shop does have an advanced CMM, it won’t need this feature because the CMM likely already has software that can do this. Another example Taylor gives is new business development. He notes that methods can vary based on shop owner — in his experience, shops run by younger people like to use social media to engage with customers, and in these cases, he can integrate Instagram, Facebook, LinkedIn and Twitter into the ERP system so shops can use it to create posts or send marketing emails.

Not only can a custom ERP be built to provide the exact functionality a shop needs, but it can also be adapted as the shop grows or changes. So if a shop adds an advanced CMM and no longer needs its ERP to create inspection documents, it can remove that functionality.

In order to build such customized systems, Taylor needs to take a personalized approach to each one. When he first initiates the ERP building process with new customers, he starts with a conversation about what exactly their workflows are, how they manage data and what they think will be important to them. He also adds his own suggestions based on his experiences. From there, he models out how the system will work so the customer can provide feedback.

According to Taylor, once the first shop implemented the ERP system, it reduced setup times, improved internal and external communication, made it easier to re-quote and run parts it had already made, and enabled it to track KPIs in the long term.

With the scope of work set, Taylor begins building the customer’s “base,” which is what Airtable calls a database. He starts with an exhaustive template base he’s developed over time. “It has absolutely everything in there, and I can just copy it, change verbiage, add and subtract fields according to what it is exactly that they need,” he says. “I customize it to the way their shop works.” This base serves as the central hub for all of the information in the customer’s ERP system. Although Airtable is user-friendly, Taylor says that he still relies on his experience with database design to know how to properly organize information and link it together.

Once the customer’s base is set up, he links it to other apps to enable automations. API calls can be used to pull information from other sources. This requires some technical expertise, but Taylor has built out a library of scripts and modules that he can re-use and modify for new customers. He still occasionally needs to program something new, but he says this library has saved him significant time. He also creates templates for documents the customer needs, such as AS9100 documentation, first article inspection and certificates of conformance. These will automatically populate with information from the shop’s base and can be sent directly to the relevant customer.

Because Airtable is cloud-based, it’s not ITAR-compliant, but it does have 256-bit encryption to keep data secure. Taylor points out that lots of other big companies use it, including some financial institutions. For additional security, he sets up two-factor authentication for every system, and designates an “owner” at each company to control access to the system within the company. He can also create separate bases that sync together if the system contains information the customer doesn’t want certain users to access. This way, a user would be able to access information about a certain job, but not the company’s financial information.

When the system is ready, Taylor provides virtual training sessions to demonstrate how the system works. He also creates training videos and documentation that users can reference later on, keeping in mind that different job functions within a shop will use the system differently (for example, an administrative employee and a machinist).

Proving Ground

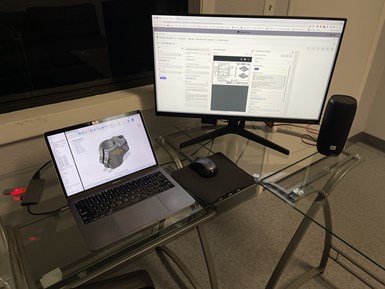

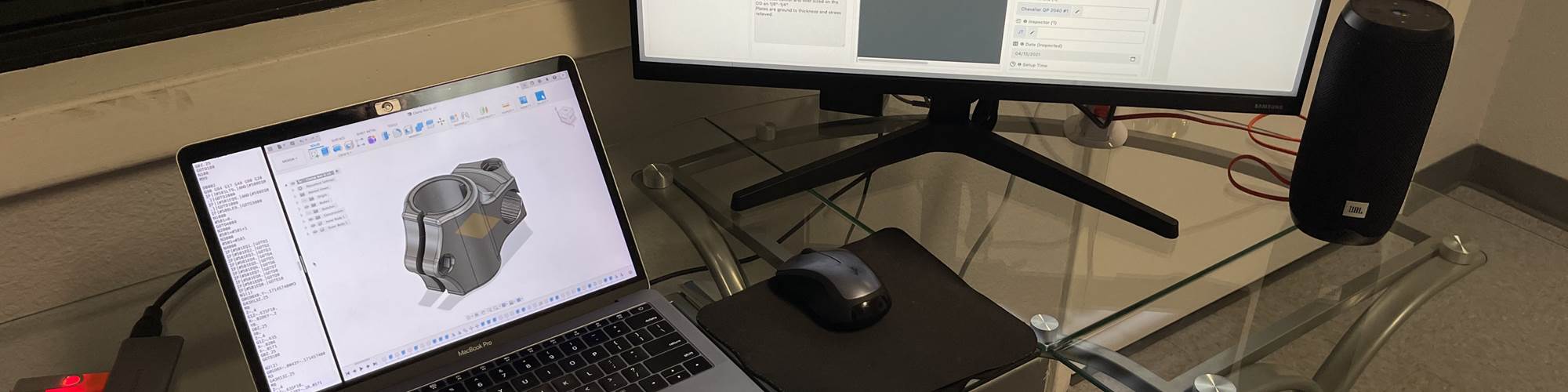

Eventually, Taylor started Defiant CNC to provide custom ERP systems to other businesses. The company also includes a small machine shop, which Taylor uses to prove and improve his product.

Building custom ERP programs isn’t the only thing Defiant CNC does — the company also includes a small machine shop. It has two employees and a few mills (one four-axis and two three-axis, including a recently acquired Doosan DNM 4500) as well as some lathes (including one five-axis lathe). The shop does mostly low-volume and prototyping jobs for a variety of end markets. “We've done things for robotic welding components, different aerospace things, components for helicopter kits and jewelry making machines,” Taylor says. “Just an array of things primarily with aluminum, and stainless steel.”

CNC machining isn’t the primary focus of the company (it accounts for about 25% of the business, while custom ERP makes up the remaining 75%), but it serves an important role — it provides a place for Taylor to prove out and refine his ERP product.

Taylor says that things are going well on both sides of the business. He’s considering hiring another employee to help him with ERP work, and he’s looking at adding a surface grinder to the machine shop. It’s something he enjoyed while working in tool and die shops, and it’s a gap he’s noticed in his geographical area. And as the shop’s capabilities expand, he notes, his own ERP system will need to adapt.

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

Cybersecurity Becomes a CNC Machining Prerequisite

Management software and information technology partner services prove their worth amid the rollout of defense industry requirements.

Read MoreERP Becomes a Communication Tool

Enterprise resource planning software modules provide at-a-glance understanding of job priority and location between departments as pandemic restrictions disrupted collaborative working environments.

Read MoreDatanomix Fusion Enables EPTAM to Visualize Facility, Optimize Resources

Faced with rising customer demand for high-precision parts EPTAM Precision Plastics used Datanomix Fusion to streamline data collection, improve quote accuracy and discover training gaps.

Read More

.jpg;maxWidth=300;quality=90)