Share

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreKnowing where a job might be at any moment and when to expect it in a specific department is critical information for all manufacturing personnel. At Crafts Technology, this information was gathered and disbursed during weekly production meetings and during daily walks of the shop floor. Until recently, this proved to be an effective communication strategy for the 100% employee-owned company, which relied heavily on teamwork and collaboration as part of its company culture.

That all changed in March 2020, when the COVID-19 pandemic began to shut down businesses. Like most manufacturers that were designated essential, Crafts Technology had to adapt quickly. Its team leads could no longer meet in the same room, so they tried holding their 45-minute production meetings spaced on the shop floor using iPads and headsets to access Zoom meetings. Production noise and masks made this a less than ideal situation. Plus, some people were working from home to limit the number of people in the facility.

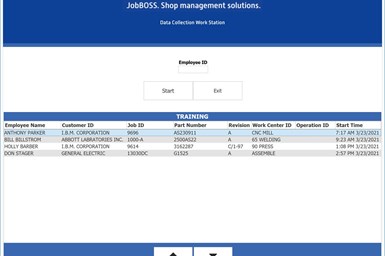

JobBoss ERP software is shown on digital displays throughout the facility at Crafts Technology to provide transparent, digital communication. Photo Credit: ECI Software Solutions

“Everything that came along with the COVID-19 restrictions was the opposite of what we were trying to achieve as an employee-owned company in terms of collaboration, teamwork and business transparency,” says Joe Abbate, technical sales manager. “When you can’t come within 6 feet of your coworkers, you have to wear masks and you can’t have groups of more than 10 people — all those things were 180 degrees from where our company was heading pre-pandemic. We really struggled with that.”

But the urgency of some of the work related to the pandemic also spurred the company to accelerate its reliance on enterprise resource planning (ERP) as a communication tool. To increase communication throughout the company, Crafts Technology decided to set up digital display boards that could give quick visualization to real-time information gathered through JobBoss, its ERP software from ECI Software Solutions. It also invested in additional modules for this software. Ultimately, the company realized a system for accurate and timely information sharing that is arguably more effective than the culture of communication it had previously been trying to build.

Accelerating Adaption

Before the pandemic, Crafts Technology was already using JobBoss at its Elk Grove Village, Illinois, facility to produce precision wear parts, components, assemblies and custom tooling from superhard materials for aerospace, nonwoven fabric, injection molding and fluid-dispensing applications. The company’s six department leads would use the ERP software to run a weekly report and print out a list of all active jobs in their departments. During production meetings, the leads would go through the hard-copy reports line by line and discuss each job based on its number and description. It was up to the leads to relay sequence of operations and timing information to their departments as needed.

This traditional, top-down approach to production management left room for improvement, and leaders at Crafts Technology had plans to set up digital displays so it could use its JobBoss ERP software as a more transparent communication tool. However, much like the proverbial can that got kicked down the street, these projects were always delayed as more pressing tasks emerged.

Then the pandemic began, and Crafts Technology took on an urgent order to produce tungsten core pin tooling used to make COVID-19 test kits. This accelerated everything in the production process — from ordering and shipping the raw material ahead of signing the official tooling contract, to freeing grinding and EDM equipment used to produce the core pins, to finally hand-delivering the finished product so it would not get lost in shipping.

It also accelerated the company’s need to streamline its communication efforts. “As soon as you bring something to the front of the line, everything else gets jumbled. If you don’t have a handle on your communication, you’re going to get derailed,” Abbate says.

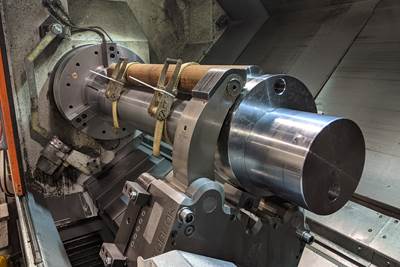

Crafts Technology produced tungsten carbide core pins in just three weeks to support the creation of COVID-19 test kits. Typical lead times for core pins run from nine to 12 weeks. Photo Credit: Crafts Technology

Communicating Job Priorities and Handoffs

Along with the JobBoss ERP software Crafts Technology had been using for years, the company decided to add two additional software modules from ECI to better communicate job priorities and handoffs. The first add-on is the Job Location Control Utility. Crafts Technology worked with ECI to customize this web-based module to show department-specific information. Each department has a custom display that shows current jobs, listed by priority, and below that is a second table that shows when jobs are coming their way. Those are also prioritized.

If a department sees that a top-priority job is headed its way, Abbate says the downstream team can collaborate more effectively with the job’s current department. He says the Job Location Control Utility has helped smooth transitions between departments. It has also helped better communicate disruptions. For instance, if work cannot be done because a job is waiting on material that is not coming immediately, the job can be put in a holding location. It will show up on a department’s to-do list, but it will not be considered active.

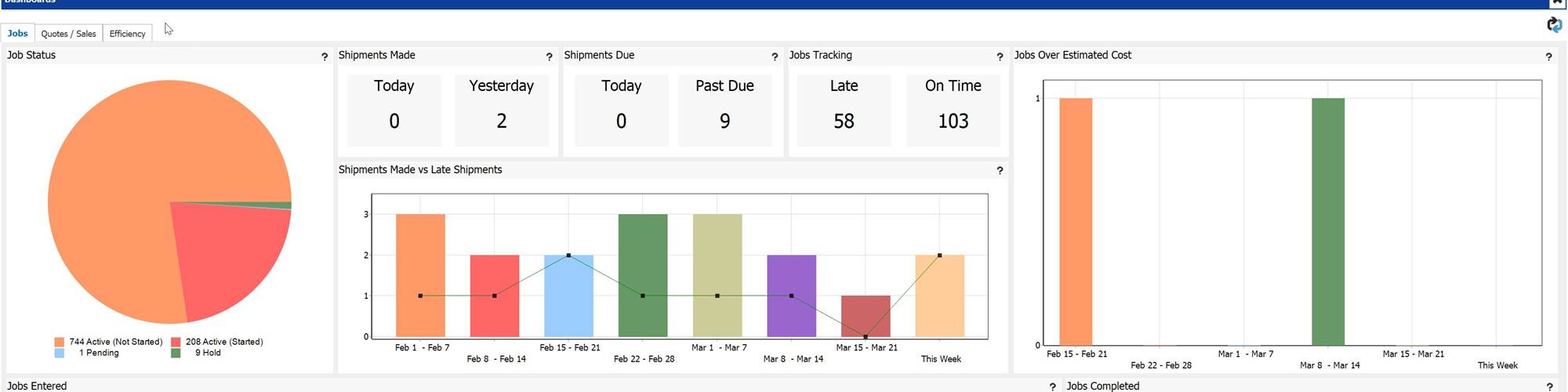

The JobBoss dashboard shows current jobs and priorities, making transitions between departments smooth. Photo Credit: ECI Software Solutions

The main benefit of the Job Location Control Utility is that it makes workflow more transparent. This is crucial information for the manufacturer’s flexibility and staffing. For example, Abbate says that if JobBoss runs an analysis on a 10-piece job and discovers that there are 150 hours of grinding work that need to be done by Thursday, management can redeploy cross-trained employees to the grinding department to complete the work on time. On the other hand, if the EDM department manager knows that the job will not make it to that department until Friday, the manager can schedule more staff at the end of the week, or even sneak in a different job ahead of schedule.

The Job Location Control Utility builds that trust by allowing for checks and balances on the shop floor.

Abbate says that most ERP systems can do this, but it is hard for people to trust them. The Job Location Control Utility builds that trust by allowing for checks and balances on the shop floor. Employees use a barcode scanner to check jobs in and out of their department. If the system says that a job is in a department when it is not, employees have the power to move the job in the system. In the end, this module builds trust because it enables two-way communication. All employees have the power to let others know when something is wrong and to correct the problem right away.

“There have been plenty of times in the past where the system has a job written up in it, and during the production meeting we discover that nobody knows where that job is,” Abbate says. “Somebody last saw it Tuesday where ‘John’ worked on it, but nobody knows where it is currently.”

A side benefit of the Job Location Control Utility is that it has changed production meetings. No longer lengthy and tedious, these meetings are now used for finding the unknowns — jobs shopfloor employees have already identified as not being in the correct location. Review and scheduling of jobs in holding locations also take place during these meetings. According to Abbate, these meetings are much more productive because somebody always has the live feed up. “We always know the system has reliable information,” he says.

ERP Automates Communication

The second JobBoss add-on that Crafts Technology is using to improve its communication is the Knowledge Sync module. According to Abbate, this software resides on the manufacturer’s server and monitors the ERP database to catch problems before they happen. When certain production, job or sales criteria are met, the module sends automatic notifications to the correct people. For example, Abbate says it can be set to look at the inventory level for a certain part number. When the inventory drops below that number, it sends an email.

Much of the grinding work at Crafts Technology is done on manual machines. Here, an employee grinds core pins. Photo Credit: Crafts Technology

Abbate says Crafts Technology relies heavily on Knowledge Sync for quality checking jobs when they are written up. “Did we add that customer? Did we forget to enter a unit price? Did we use a routing operation that is obsolete?” The manufacturer also uses Knowledge Sync for automating the distribution of reports. It runs an Orders and Trends sales report that looks at the six-month trends, compiles the list and emails that report to five or six people. While Abbate says this only saves him about 10 minutes per week, the real savings is in timing and reliability. “If I’m working from home or on vacation, the report can still be set to automatically send at 9 a.m. on Monday versus Tuesday at lunch or whenever I am back in the office, working on that task,” he says.

Crafts Technology has also deployed a custom application for the part of the business with repeat jobs. This application streamlines the job creation probcess by allowing jobs to be created right from the shop floor. According to Abbate, all job creation used to take place in the office, but now a repeat job is simply scanned in, a label is printed, and the job is off and running.

Digital Communication Leads to True Collaboration

According to Abbate, Crafts Technology is modernizing in terms of digital communication, but doing so on its own terms. “We’re doing things that our people wouldn’t have stomached right out of the gate. We’re heading toward the future, but we are doing it our way, and we are getting the most bang for our buck,” he says.

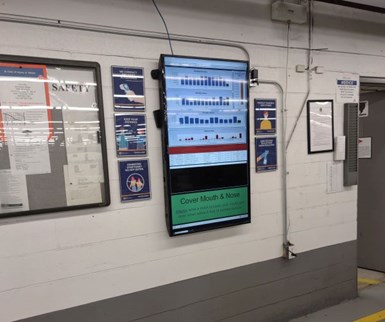

Along with digital displays in each department showing job location information, Crafts Technology has implemented a central display that can show larger-picture information such as financial info, who has been cross-trained in various departments and more. Photo Credit: Crafts Technology

Abbate is excited to see how streamlined, digital communication is being embraced by employees. For example, he tells the story of how an employee who did not want a computer on the shop floor is now providing constructive feedback on jobs using the digital information he now has at hand. “It’s cool to see that he’s understanding the system and adding value to the whole scenario,” Abbate says. “The ERP system is a point of engagement on the shop floor — people are now talking the same language that we’ve been talking in the production meetings and scheduling. Our new communication system gives more opportunity to provide feedback.”

According to Abbate, the ultimate goal in streamlining communication was to provide transparent information to everybody. “I can’t expect somebody else to make the same decision I would if they don’t have the same info. If we want people to make good decisions, we have to give them good info.”

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

CNC Machine Shop Reaps Benefits of Hiring an IT Person

A database guru combined off-the-shelf technology with an elaborate proprietary shop management software to drive efficiency throughout all areas of a machine shop.

Read MoreLet’s Finish Closing the Quoting Gap

Sharing accurate, timely and actionable data is the key to an effective, respectful relationship between a machining job shop and the subcontracting finishing shop. Software that streamlines the quoting process can make this happen.

Read MoreContinuous Improvement Requires Continuous Effort

So-called “busywork” hones natural instincts for reform as a specialist CNC machine shop adapts a more formalized methodology.

Read More

.jpg;maxWidth=300;quality=90)