HyperMill Five-Axis Modules Simplify Complex Part Machining

Open Mind’s HyperMill CAM software includes powerful five-axis milling modules that decrease machining times for complex parts, as happened at NDK Paragon.

Share

The HyperMill CAM software suite from Open Mind Technologies enables a wide range of five-axis machining strategies.

Nick Katrov is the chief technical officer and sole machinist at NDK Paragon — a 3,800-square-foot shop located in Oceanside, California. The shop is co-owned by his wife, Tina Torabi, who is the CEO. NDK Paragon serves the aerospace, semiconductor and medical industries, and Katrov uses three CNC machining centers for its complex jobs: two Mikron five-axis models — one of which has a seven-pallet system tuned for lights-out manufacturing — and a Doosan three-axis system. He also uses a Hexagon CMM with full scanning capability.

As a job shop with high-mix, low-volume orders, precision, accuracy and reliability are paramount. “All of our applications require very fine surface finishes of better than 8 microinches Ra, in addition to high dimensional and true position tolerances with tenths-level accuracies,” Katrov notes.

Tackling complexity with HyperMill

Working on complex parts in this high-precision environment, especially in a one-machinist shop, required a robust, reliable CAM platform to drive key high-performance, five-axis machining strategies. Katrov found this platform in Open Mind Technologies’ HyperMill, a complete CAM software system with one postprocessor for maximum process reliability, minimized machining times and cost efficiency.

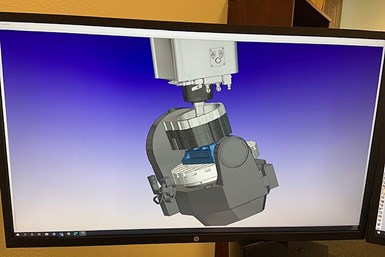

NDK Paragon’s Chief Technical Officer and sole machinist Nick Katrov programs and runs a machining simulation with HyperMill.

“With our applications requiring full five-axis strategies, we have successfully utilized most of the five-axis modules in HyperMill such as contouring, tangent milling with barrel cutters, swarf milling and helical drilling,” Katrov explains. He says he was particularly impressed with the simplicity and seamlessness of the CAM software for programming complex jobs. On top of that, he says the part simulation saved setup time and reduced scrap on account of its accuracy. HyperMill’s reliability enabled Katrov to focus on daily tasks in the shop, secure in the knowledge that the software would work properly.

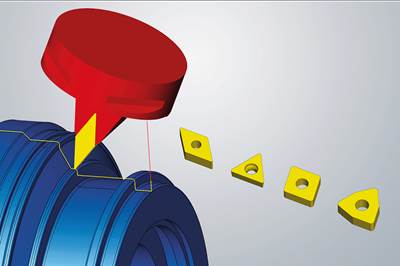

Saving money with standard tooling

Utilizing tangent milling with barrel cutter strategies from the HyperMill Maxx Machining performance package has enabled the shop to manufacture very complex components with standard tooling, which has reduced cycle times by as much as 70%, Katrov says. “And there are times when this tangent milling with barrel cutters feature provides the only way to effectively machine the required shape of a customer’s part,” he says.

In addition to tangent plane machining, Katrov also relies on other HyperMill features for time and tooling cost savings. One such feature is five-axis helical drilling, which enables him to use regular end mills to helically drill large holes at high feed rates. A high-precision surface module, which enables him to mill fine surface finishes, and advanced part probing cycles for the Heidenhain Control have also enhanced Katrov’s operation. “Open Mind Technologies postprocessing is clean and accurate. We have never needed to make manual edits to make the programs run properly,” he says.

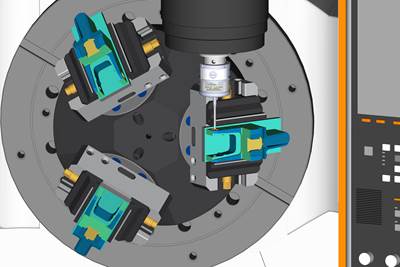

HyperMill CAM software includes support for five-axis cavity milling.

Versatile features

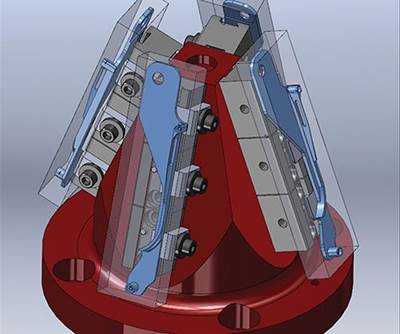

The HyperMill CAM software suite includes a wide range of powerful five-axis strategies designed for machining challenging geometries, free-form surfaces and deep cavities at maximum efficiency levels. Users can choose between five-axis machining with a fixed tool angle, automatic indexing or true simultaneous machining. All toolpaths generate fully automatically with collision checking and avoidance.

The performance package of the HyperMill Maxx Machining offers three modules for drilling, roughing and finishing that are designed to help users achieve optimal rates of machining productivity. According to Open Mind Technologies, five-axis helical drilling uses standard cutters to open large areas prior to roughing and uses a five-axis helical tool path to efficiently remove material and evacuate chips. The roughing module, which is designed for fast, reliable machining, includes cycles for milling spiral and trochoidal tool paths. It also includes options that identify large inscribed rectangles or circles within components to optimize machining with simple tool paths and complete the pocket by identifying the regions with remaining material. Dynamic feed rate adjustment according to actual cutting conditions ensures consistent milling at the highest possible rates. This results in optimal milling paths with maximum material removal. The package also supports high-performance roughing of both prismatic and curved component faces with five-axis techniques.

Algorithms in the HyperMill CAM software are designed to ensure continual removal of a constant chip volume. This delivers high utilization rates without exposing the tool to undue stresses, resulting in roughing speeds up to 70% higher than conventional milling, the company says.

Open Mind Technologies says its HyperMill five-axis tangent plane machining enables cycle time reductions of up to 90% when used with conical barrel cutters. In addition, stepover widths of 6-8 mm or more are possible with the large radii of conical barrel cutters, resulting in smooth surface finishes and improved tool life.

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

HyperMill 2020 Updates Include Advanced Automation Center

Open Mind hyperMill 2020 CAD/CAM software incorporates an advanced automation center and user-friendly enhancements to simplify the machining process.

Read MoreCAM Software Helps Shop Gain Machining Efficiencies

VIDEO NOTE: Scroll to the bottom of the page for a behind-the-scenes look at 5th Axis, and hear Chris Taylor talk about how Hypermill software has helped his company.

Read MoreSimulation Gets Real

Capability to generate something close to a true digital twin can significantly improve confidence in CAM program prove-outs.

Read More