Hydraulic or Pneumatic Actuation for Collet Blocks?

Collet-style workholding devices like collet blocks offer a number of benefits, but which actuating method is most appropriate for you?

Share

Takumi USA

Featured Content

View More

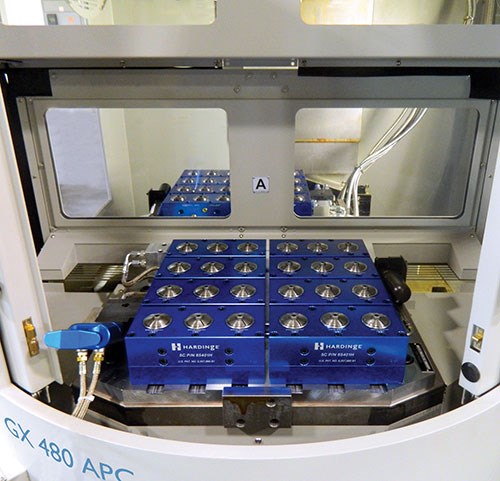

Grouping collet blocks together enables machine tools to machine multiple parts unattended. Collet blocks can be configured in a number of ways, including on tombstones and trunnion tables.

Collet-style workholding devices, such as collet blocks, offer a number of benefits. Collets automatically center parts to their center points known locations, they provide equal gripping pressure around a part’s circumference and expanding collet systems enable effective internal gripping of thin-wall parts. Grouping collet blocks together enables machine tools to machine multiple workpieces unattended over long stretches of time. However, should you go with pneumatics or hydraulics to actuate them? This article based on input from Hardinge offers advice.

Related Content

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)