"Hybrid" Manufacturing Process Combines Deposition and Laser Peening

Research at the University of Nebraska-Lincoln is combining directed energy deposition (DED), a metal 3D printing process, with laser peening for improved mechanical properties.

Share

Dr. Michael Sealy at the University of Nebraska-Lincoln is exploring combining laser peening with deposition using this Optomec LENS 860 hybrid system. Photo: University of Nebraska-Lincoln

When we talk about “hybrid manufacturing” we usually mean some combination of 3D printing and milling technology. But at the University of Nebraska-Lincoln, hybrid means something else. Dr. Michael Sealy is combining metal directed energy deposition with a different type of secondary process: laser peening, applied between 3D printed layers.

The specific machine used for this procedure is an Optomec LENS 860 hybrid machine tool. LENS stands for Laser Engineered Net Shaping (LENS), a powder-based directed energy deposition (DED) process used for repairing parts as well as building them up from scratch. In its hybrid configuration, the DED capability is more often paired with a milling head that might be used to cut off damaged portions of a part, tap holes or finish machine a part.

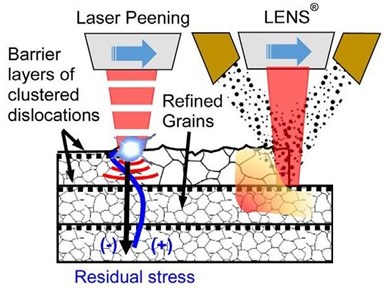

The hybrid process uses LENS deposition followed by laser peening to strengthen the material.

Figure: https://doi.org/10.1016/j.cirp.2019.04.105

The laser peening capability promises something different: “lightweight structures that have higher strength than you can achieve with just 3D printing by itself,” Dr. Sealy says. Applying laser peening can strengthen material in specific areas or universally, potentially resulting in a stronger part made with less material. To borrow a term from the business world, Dr. Sealy refers to this strategy as a “glocal” approach, or one in which local changes have global impact.

The first application Dr. Sealy is exploring for this hybrid technique is medical implants. Specifically, his research is focusing on femur implants made of magnesium, a material that could be absorbed by the body over time. Laser peening applied between layers could manipulate not only the strength of such implants, but their rate of degradation as well.

Read more about this research and the “glocal” approach to hybrid manufacturing in this article on the Additive Manufacturing website.

Want to learn more about 3D printing?

Sister publication Additive Manufacturing explores how manufacturers are applying 3D printing to make tooling, molds, functional prototypes and end-use parts. Subscribe.

Related Content

-

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

-

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

-

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)