Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Images provided by Fagor Automation

A machine feature that works for one shop might not work for another. Computer numerical controls (CNCs) can play an important role in adapting a machine to a manufacturer’s needs through the development of custom interfaces and the integration of peripherals, such as machine monitoring programs, coolant control systems and probes. However, implementing these customizations often requires high-level programming expertise as well as cooperation from the OEM (and/or third-party companies in the case of peripherals).

Fagor Automation is touting another way. Rather than employing a custom application programming interface (API) to build the new HMIelite, the company chose HTML5 — reportedly an industry first. As a relatively simple, intuitive programming language, HMTL5 is expected to make machine tool customization easier and faster while also adding a layer of security, which can be an important consideration in an era of interconnected machinery and manufacturing operations. The HTML-based HMI is expected to become standard on all the company’s Windows-based controls in 2022.

Custom Screens

As a developer of CNCs for all manner of machines and processes, Fagor sees the potentially wide-ranging impact in making interfaces easier to customize. For example, HTML might enable an OEM to remove functionality from a screen to make it simpler, or an end-user to create a custom button that starts certain processes.

The benefits of easy customization go beyond flexibility. For example, custom screens can make learning to operate a machine tool easier. “It's not only the CNC,” notes Artur Gugulski, application sales at Fagor Automation. “It's easier to handle the whole machine.” A well-designed interface can ease navigation and keep machine operators focused by presenting only relevant information. He adds that custom screens can also help ease maintenance. Having a control that’s well organized and easy to navigate makes remote troubleshooting and machine maintenance faster.

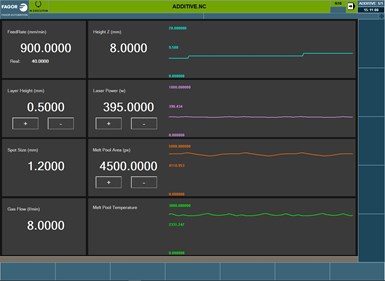

Using Fagor’s API to build custom CNC screens like the one for this industrial 3D printer can take weeks, even with deep in-house programming expertise.

Previously, building custom screens for a Fagor control required the company’s custom API. Additional screen-building software that sits atop the API was designed to make this process easier, but the task could still take weeks, even for companies with in-house knowledge of programming languages, such as C Sharp, C++ and visual basic. “Giving an API to an end-user, sometimes they don't have the capabilities of developing software, and they don't know how to use the API correctly,” says application engineer Thiago Miranda. “You need a little bit more advanced programming knowledge.”

But with an HMI built on HTML, anyone with web design experience can build a custom screen in days. Ryan Adamovic, senior marketing coordinator, cites the example of a customer that switched to the new, HTML-based HMI. This switch meant recreating a custom control screen for the customer's industrial 3D printer, but the process was much faster with HTML than it was with the API. It also provided an opportunity to update the screen's design, functionality and scaling. “They were able to recreate the custom screen in a fraction of the time and actually make it look more pleasant to the end-user,” he says.

The company estimates that about half of its controls already use some type of custom screen, but switching to a more accessible HTML-based HMI could increase this number. “It's way easier to find somebody who knows web development than somebody who's going to build a full software program from scratch on C Sharp,” Miranda says.

When the metal AM user switched to the HMIelite, it rebuilt the screen using HTML. The process was much faster than with the API, and the user was able to update the screen with a new design, functionality and scaling.

Machine Monitoring

An HTML-based user interface also has benefits for shops that have implemented or plan to implement peripherals on their machines. For one, because HTML is more common and easier to use, it’s easier to integrate with third-party systems for machine monitoring, coolant management, probing, tool breakage detection and adaptive control. Downloading an app to the machine control is more convenient than contacting the OEM and getting the API, then finding someone who can create the software to integrate them. Gugulski sees such capability as an initial step toward a future when machine tools are more open to modification, and when integration is more like installing new office equipment. “Connecting a new PC to your network should be simple,” he says.

HTML5 also enables users to design custom screens that are responsive; that is, they scale to the display of the viewing device, Miranda says. Responsive displays are critical for properly viewing information such as job numbers and machine status on tablets and cell phones.

Security

The use of HTML also enables a new security feature on Fagor’s controls. HTML’s geolocation function enables users to restrict remote access to the control based on location parameters. This means that only users within certain towns or even a specific building can log into the control. This gives an extra layer of security if login credentials are compromised. Adamovic adds that custom screens and other features enabled by the HMTL-based CNC front-end can be just as useful for manufacturers that prefer not to connect their machines to the internet.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Custom Control Adds Accuracy, Flexibility to New Machine Tool

A new boring-mill machine with a custom control is helping a shop hold tighter tolerances and accommodate rapid travel rates for faster machining.

Read MoreCNC Machine Shop Reaps Benefits of Hiring an IT Person

A database guru combined off-the-shelf technology with an elaborate proprietary shop management software to drive efficiency throughout all areas of a machine shop.

Read More5 Things New CNC Machine Operators Must Know

These subjects are the building blocks of training newcomers on a specific CNC machine tool.

Read More

.jpg;maxWidth=300;quality=90)