Share

Read Next

Much has been made of high efficiency milling in recent years, and for good reason. Roughing cycle times can often be reduced by as much as 80% by using solid end mills, small stepovers, faster feed rates and deeper axial depths of cut. The shortcoming has been that, due to part feature obstructions or CAM system limitations, the cutting technique can often only be used in certain areas of a part so that total part cycle time reduction ends up being much more modest.

CAM developer SolidCAM has an answer for this with its iMachining technology for both 2-axis Z level and full 3D machining. According to Dr. Emil Somekh, the Founder and CEO of SolidCAM, with the ability to intelligently generate high efficiency tool paths for a wider range of cutting conditions, iMachining can reduce total cycle times by as much as 70% and more and deliver dramatically longer tool life in the bargain.

Constant Chip Thickness is the Key

The key to being able to cut faster and improve tool life is to keep a constant force load on the cutter. This reduces the shocks and vibration that occur when material engagement changes abruptly, for example, when a tool hits the corner of a pocket. In high efficiency machining this is most often accomplished by manipulating the tool path to keep tool stepover and feed rate constant, which can result in highly variable chip thickness and force load on the tool. Because the process requires a climb cut, this can also create a lot of air cutting time when repetitive unidirectional passes are required. And it tends to limit use of the technique to certain open features of the part.

Dr. Somekh says iMachining applies a much more flexible approach with the patented ability to dynamically vary the tool cutting angle (which refers to the degree of radial engagement of the tool with the material) and the feed rate in order to maintain a constant chip thickness and load on the cutting tool. The dynamic feed rate adjustment algorithm supports material cutting angles from 10 to 80 degrees of tool engagement. Constant load and chip thickness is key to the success of iMachining, also with very small cutters and machining in hard or highly abrasive materials.

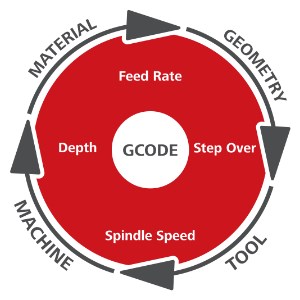

iMachining Technology Wizard automatically generates programs taking account of all elements of the machining process including tool path, feeds, and speeds, material machinability, tooling, and machine capabilities.

SolidCAM accomplishes this tool path optimization with two modules:

- The iMachining Technology Wizard provides SolidCAM’s iMachining algorithm with the parameters to automatically calculate the optimal varying feed rates for each point of the toolpath to maintain constant cutting force on the tool for any stock material, cutting tool type and CNC machine.

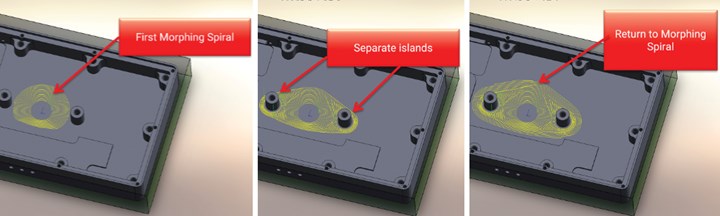

- The Intelligent Tool Path Generator calculates efficient, mainly morphed spiral tool paths, incorporating D-Slot Trochoidal motion where necessary when the user defined ‘Cutting Angle Range’ requires it. This keeps Spiral Morphing at its optimum efficiency while using the cleanest motion for joining discontinuous regions in the most effective manner.

Combined, these modules apply extremely sophisticated logic to generate the most efficient CNC part programs for any given machine. In fact, machine attributes – max feed rate, spindle speed, HP – and such are used by the wizard to get the best results for a specific machine, tool and material.

Intelligent Tool Path Generator creates spiraling cuts wherever possible to maximize cutter engagement time. In cases where part features obstruct the path, it incorporates the features and continues spiraling.

Keeping the Tool Engaged

The Spiral Morphing tool path generator is a key enabler to generating the most efficient programs. By maximizing a continuous spiral cutting path, iMachining produces the most efficient cutting strategy because the tool is constantly engaged in the material for greater durations. Part features such as islands or bosses can limit the extent to which the technique can be used. However, the iMachining toolpath algorithm automatically recognizes these features, creates trochoidal tool path around them to incorporate them into a larger pattern, and then continues a spiral path around them to complete a Z-level with the highest percentage of cutter engagement time possible.

iMachining’s patented algorithm is used in iMachining 2D and iMachining 3D. iMachining 2D is made for the roughing and finishing of 2D features, sometimes referred to as prismatic geometry. iMachining 3D is made for the roughing and semi-finish of complex 3D surfaced parts. iMachining 2D uses Machinable Feature Recognition to make geometry setup easy with a single click on a face and iMachining 3D gives the shortest cycle time using its scallop-based roughing.

This constant load cutting strategy is critical for extended tool life. iMachining has been shown to not only give better Material Removal Rates (MRR) than any other toolpath technology, but also amazing increases in tool life... Most people assume that since iMachining is more aggressive with the cutting speeds and feeds, that it should wear out the tool sooner. So how is it that iMachining provides much better tool life?

To understand this, we must first understand solid Carbide Cutters. Carbide is an extremely hard material - it can stand up to compressive forces beyond most other materials and it is also highly resistant to abrasives. These factors make it a great material to use for Cutting Tools, used for cutting Steel, Super Alloys, and most other Metals. Along with being extremely hard, Carbide is also very "Brittle" - it will not stand up to Tensile Force (Bending Force) very well at all.

iMachining ensures that the carbide substrate at the sharp edge of the solid carbide tool flute never sees tensile forces - it only sees compressive forces. Therefore, the sharp edge resists micro chipping, even at elevated performance levels as seen with iMachining, resulting in dramatic improvements to tool life - no other system can manage this balance as well as iMachining.

One other large factor in increasing tool life is the ability to run tools with their full depth of cut. In the past, in order to avoid putting too much stress on brittle tools, other systems would only make shallow cuts to compensate for over engagement. With iMachining, making use of the full cutting depth of the tool, never over stresses it and actually spreads the forces out over a greater area, further maximizing tool life by using the full length of the flute instead of just the bottom 10%.

There is so much more to be said about iMachining, and its amazing successes for customers, we can’t do it justice here. Watch the below interview with SolidCAM’s Ken Merrit, giving an in depth look at iMachining.

More on iMachining

Learn more at SolidCAM.com or register for an online demonstration with a SolidCAM expert.