How Machine Tools Can Save Energy

It starts with energy-efficient designs of the servo and spindle systems. This article introduces useful concepts such as the difference between direct and indirect energy consumption.

Share

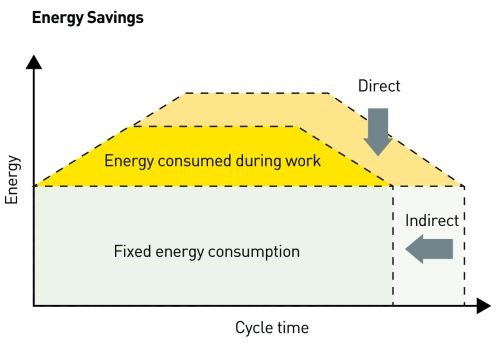

Energy usage is becoming a more important factor in determining the overall efficiency of automation systems, including CNC machine tools. Conserving energy cuts costs and protects the environment. An article by Paul Webster, engineering manager at FANUC FA America, explores the topic and focuses on the value of modern electrical motor design for CNC machine tools, injection machines and other automated production equipment. “Energy Saving Designs in Factory Automation Equipment” also introduces a number of key concepts in energy consumption and efficiency strategies.

Related Content

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

.jpg;maxWidth=300;quality=90)