How a Worksheet Can Elevate AM Success

How a simple worksheet can help improve success with additive manufacturing.

Share

Takumi USA

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

The past couple of months, I have been discussing the challenges of teaching people to leverage the design and material freedoms associated with additive manufacturing (AM) to develop new and creative solutions as well as innovative business models that disrupt current products and practices. Achieving the full power of AM requires understanding both the opportunistic and restrictive aspects of the technology. The distinction between these aspects was first introduced by a team of doctoral students and faculty working at the Ecole Nationale Supérieure d'Arts et Métiers (ENSAM) in Paris, France, and I want to expand on them.

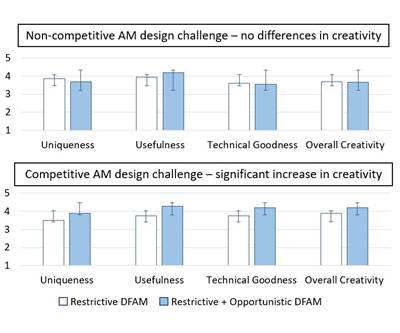

The opportunistic aspects are what drive the hype. These include all of the things that are made possible by AM that are not easily done with a traditional manufacturing process such as the ability to create lightweight structures that mimic nature, the ability to consolidate multiple parts in an assembly into a single 3D-printed component, and the ability to mass customize or functionally grade a component for different users and/or uses. The Design Heuristics for AM cards that I highlighted last month is one embodiment of the opportunistic aspects of AM. Using these cards in the early stages of design can improve the creative solutions generated by novices.

On the flip side, the restrictive aspects represent the realities of the technology. These include the limitations that are inherent in the layer-by-layer fabrication of a 3D solid object such as overhang angles that may need support structures, thin walls that may distort or fail to build properly, and residual stresses that may lead to warping as the material heats up and cools down. The full list of restrictive aspects and corresponding failure modes can be pretty overwhelming, and it is important to carefully balance the restrictive and opportunistic aspects to give anyone a realistic preview of what AM can or cannot achieve. The AM Design Principles cards that I referenced last month include some of the restrictive aspects of AM alongside the opportunistic aspects; however, the cards have only been shown to improve the novelty and quality of ideas generated by novices. The feasibility of those designs was not considered as part of their initial study.

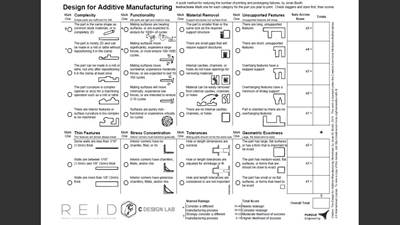

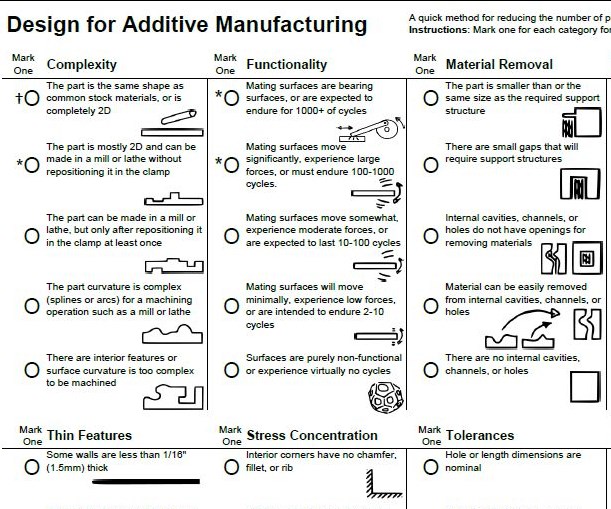

Shown here is a portion of the Design for Additive Manufacturing (DFAM) Worksheet developed by Dr. Joran Booth as part of his graduate studies at Purdue University significantly reduced the number of build failures when given to students. Source. The full worksheet can be found here.

Enter the Design for AM (DFAM) Worksheet by Joran Booth as part of his doctoral studies at Purdue University with Dr. Tahira Reid and Professor Karthik Ramani. Available free under the Creative Commons license, the DFAM Worksheet provides a quick checklist to determine whether a part is suitable for AM. Eight criteria are included, most of which focus on the restrictive aspects of AM. For instance, guidelines for thin features, unsupported features and stress concentrations are provided along with considerations for tolerances and geometric exactness. The simple spreadsheet format makes it easy to filter out bad designs, and the team observed an 81% decrease in the rate of poorly designed parts printed by students in their makerspace.

While the worksheet was developed for material extrusion AM systems, the eight criteria can be easily tailored to other AM processes. For instance, we have developed a customized version of the worksheet to help companies screen metal parts for powder-bed fusion processes. This is done by adapting the ratings in each column to the specific AM system in use. Alternatively, new criteria, like the extent of postprocessing needs or the ability to inspect a metal AM part, can be substituted or added to the worksheet if it is an important consideration for an AM process.

I have also used the DFAM Worksheet during brainstorming sessions to help identify parts that are not good for AM. The worksheet recommends that a low-scoring part be redesigned for AM. In other words, the part is not a good candidate in its current instantiation for AM. In fact, there are several starred ratings in the worksheet that are immediate triggers to consider a different manufacturing process. For metal AM parts, a flight critical component might trigger such a review if “part criticality” were added as a criterion to the spreadsheet. I have seen this criterion appear as an important screening factor in many AM part identification methods and qualification/certification documents, and while it should not eliminate the part from consideration, it is an easy way to flag it for further review.

We need innovative methods to capture and transfer knowledge about AM in order to be more creative with AM.

While textbooks and guidance documents are still important, the success of DFAM worksheets and custom DFAM cards should challenge us to think more creatively about how we capture and convey the opportunities and restrictions of the different AM processes. In other words, we need innovative methods to capture and transfer knowledge about AM in order to be more creative with AM.

Related Content

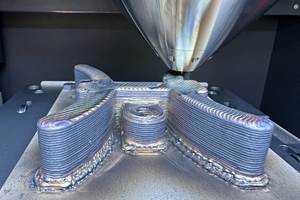

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

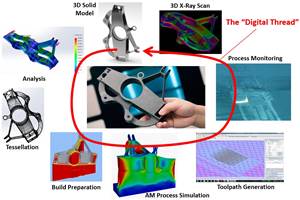

Read MoreGo Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read MoreRead Next

Students Develop Design for Additive Manufacturing (DFAM) Worksheet for 3D Printing Success

A team of researchers at Purdue University developed and tested a DFAM worksheet to help novice and intermediate 3D printing users increase build success and minimize reprints.

Read MoreThe Challenges of Teaching Creativity in Additive Manufacturing

The extensive design freedoms offered in additive manufacturing can be paralyzing. With AM consistently pushing the boundaries of manufacturing, how do we teach people to take risks and be creative with AM?

Read MoreCard Decks Leverage Additive Creativity

How custom card decks are helping people be more creative with AM.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)