High-End Watchmaker Eliminates Offshoring with Five-Axis Machining Center

Instead of shipping small components from overseas, a watchmaker was able to accommodate increased demand by purchasing a used five-axis machining center.

Share

Sydney, Australia, might not come first to mind when thinking of places known for high-quality timepieces. Nevertheless, Nicholas Hacko, owner of Nicholas Hacko Watchmaker (otherwise known as NH Watches) has succeeded in carving out a space for himself doing just that. But crafting $1,200 to $11,000 watches requires fashioning tiny parts at micron-level precision.

In the past, the company had no choice but to source the required small components from an external supplier. Being a minor customer, NH Watches was not always high on the supplier’s priority list. In addition, because the plates, gears and other parts required by NH Watches were primarily produced overseas, the part deliveries were sometimes subject to unforeseeable delays.

In order to remain flexible and competitive in the face of such challenges, Mr. Hacko invested in a high-precision five-axis machining center from Germany-based Kern Microtechnik, enabling him to reliably produce in house the micron-accurate parts that are the basis for his business.

With Success Comes the Need to Micromachine Parts in House

Originally from Europe, the Hacko family has a long tradition of watchmaking. In fact, Mr. Hacko is a third-generation watchmaker. He founded NH Watches in 2011 to repair watches and manufacture replacement parts. Five years later, he manufactured the company’s first watch designed in house. The company soon achieved success manufacturing and selling watches, surpassing its original goal of selling 100 watches per year, with demand only increasing.

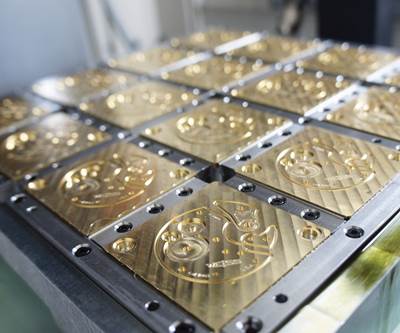

The need to produce the micro parts in house became acute. NH Watches needed a machine capable of achieving accuracy between 6 and 10 microns in order to ensure that the watches keep perfect time throughout their lives. In exceptional cases, XY pitch accuracy of just ±2 microns must be met when drilling and interpolating holes in metal plates.

Mr. Hacko cast his eyes back to Europe to find the technology he needed. During Germany’s 2016 AMB metalworking trade show, he saw a machine from Kern Microtechnik that caught his eye. The following year, he visited Kern at its machine engineering factory in Eschenlohe, Germany, to discuss options, including the possibility of purchasing a used machine.

That summer, when a Swiss luxury watch company replaced a Kern Pyramid Nano with a new Kern milling center, Mr. Hacko jumped on the chance to buy the used machine.

More Than Enough Accuracy

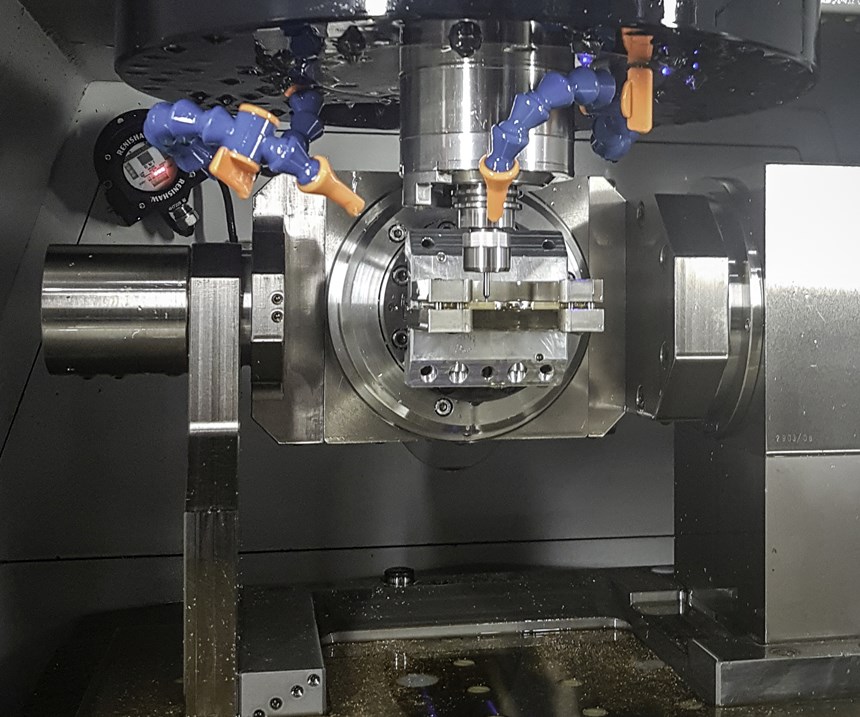

The Pyramid Nano is a high-precision five-axis machining center. Developed for ultra-precise production, it is said to achieve machining accuracy of less than 1 micron throughout its entire service life. “This machine mills very small gears, bridges, pallets, mainplates and other micro parts with greater precision than is actually necessary,” Mr. Hacko says. The model he owns provides axis-motion accuracy of ±0.3 micron and processing speed of 30 meters per second.

The machine is equipped with complex hydrostatic guides and drives that are not subject to mechanical wear and tear. The hydrostatic properties also damp vibrations, meaning that acceleration rates as fast as 10 meters per second have no effect on machining accuracy, the company says. Reflecting on the fact that the machine is designed to maintain precision through its entire service life, Mr. Hacko says, “It’s just like my watches.”

A small team from NH Watches was invited to receive training at Kern’s Eschenlohe training center. During their visit, the Australians learned the skills needed to reliably produce high-quality parts on the machine, including programming with Heidenhain conversational code, using the right tools and setting up the machining center. It has been running with the help of Kern’s teleservice support since March 2018, and Mr. Hacko says the machine “produces each part exactly as we program it. It simply doesn’t make any mistakes.”

Micromachining Center Enables New Business

Mr. Hacko believes that two factors are equally crucial for the success of his brand: his seven motivated employees, three of whom are apprentices learning the watchmaker’s trade, and the machining technology, particularly the Pyramid Nano.

Taking advantage of its new production capability, NH Watches recently became a contract manufacturer for other industrial companies that need micro parts. With no significant competition for this service nearby, Mr. Hacko is now expanding his business by supplying several companies in the Australian medical and moldmaking industries.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More