Hard Turning Might Not Be As Hard As You Think

Turning hardened materials to grinding-like accuracies takes the right combination of part, machine and process parameters.

Share

The clear attraction to hard turning is the possibility of eliminating grinding operations. For some shops, though, the process of repeatedly turning parts that are harder than 45 Rc to grinding-level accuracies is still a bit cloudy.

A properly dialed-in hard turning process can deliver surface finish of 0.00011 inch, roundness of 0.000009 inch and diameter tolerance of ±0.0002 inch. Such performance can be achieved on the same machine that "soft" turns the part prior to hardening, maximizing equipment utilization. However, some shops misstep by initially using the wrong (that is, less expensive) tool insert for the application. Others may not be sure if their machine possesses the rigidity to handle cutting pressures that can be twice that of a typical turning operation.

Tom Sheehy, application engineer for Hardinge, Inc. (Elmira, New York), shared some of his company's hard turning advice and insight. Here are eight key process elements that shops should keep in mind when taking a hard look at hard turning.

• Part—Though 45-Rc material is hard turning's starting point, hard turning is regularly performed on parts that are 60 Rc and higher. Commonly hard-turned materials include tool, bearing and case-hardened steels, as well as Inconel, Hastelloy, Stellite and other exotic materials. From a metallurgical standpoint, materials with a small hardness deviation (less than two Rc points) throughout the cutting depth allow the best process predictability.

In some cases, a part's size or geometry simply does not lend itself to hard turning. Parts that are best suited for hard turning have a small length-to-diameter (L/D) ratio. In general, an L/D ratio for unsupported workpieces should be no more than 4:1, and it should be no more than 8:1 for supported workpieces. Despite tailstock support for long, thin parts, high cutting pressures would likely induce chatter.

• Machine—The degree of machine rigidity dictates the degree of hard turning accuracy. Most machines made in the last 15 to 20 years have sufficient rigidity to handle some hard turning applications. In many cases, a machine's overall condition is more of a factor than its age. Even an old, well-maintained manual lathe can be a candidate for hard turning. However, as required part tolerances get tighter and surface finishes get finer, machine rigidity becomes more of an issue.

Hardinge has integrated a number of features in its turning centers to increase rigidity and damping characteristics for hard turning applications. These include machine bases with polymer composite reinforcement, direct-seating colleted spindles that locate the spindle bearing close to the workpiece and hydrostatic ways.

Maximizing system rigidity means minimizing all overhangs, tool extensions and part extensions, as well as eliminating shims and spacers. The goal is to keep everything as close to the turret as possible.

• Inserts—Some shops are initially put-off by the high cost of cubic boron nitride (CBN) inserts, despite the fact that these inserts are the best all-around grade for hard turning. CBN inserts hold up well during interrupted cutting and offer good tool wear for continuous cutting. With a properly tuned hard turning process, these inserts are second only to grinding in terms of holding diameter tolerances.

Ceramic is not as tough as CBN, and it normally is not used when tolerances are tighter than ±0.001 inch. Ceramic is not appropriate for interrupted cuts, and it should not be used with coolant because of the risk of damage resulting from thermal shock. Blunt edge geometry is inherent to this material, which translates into higher cutting forces and reduced surface finish. In addition, failure on a ceramic insert can be catastrophic and render all cutting edges unusable.

Cermet (solid titanium carbide) works well for continuous cutting of case-hardened material. Though it does not offer the wear resistance of CBN, it tends to wear proportionally under most circumstances rather than breaking.

Negative-rake inserts are typically used because of their robust cutting edge. However, positive-rake inserts may permit hard turning on machines whose rigidity is suspect, thanks to lower cutting forces versus negative profiles.

The best advice regarding inserts is to work closely with a tooling supplier, especially at the beginning of the process, in order to get up to speed quickly.

• Coolant—The biggest question with respect to coolant is whether or not to use it. For parts, such as gears, that have interrupted cuts, it is best to run dry. That is because the thermal shock the insert would experience exiting and entering cuts would likely cause breakage. For continuous cuts, the high tool tip temperatures that occur in dry turning serve to anneal (soften) the pre-cut area, which lowers the hardness value and makes the material easier to shear. This phenomenon is why it is beneficial to increase the speeds when cutting dry. Cutting without coolant provides obvious cost benefits as well.

Coolant can be helpful for continuous cutting applications in terms of providing longer tool life and better surface finishes. The key is to get the coolant to the tool tip. High-pressure coolant is the best bet for reaching the tool tip, and it is not likely to vaporize because of the high temperatures. High pressure also serves to keep chip size small, which reduces the chance that the chips will block coolant from reaching the tip. Another way to ensure that coolant continuously reaches the tip is to deliver the coolant to both the top and bottom of the insert.

If a coolant is used, it must be water-based. A chip formed through a properly configured hard turning process takes with it 80 to 90 percent of the heat generated (cutting zone temperatures can reach 1,700°F). If such a blazing chip would contact straight-oil coolant with a low flash point, the process could literally go up in flames. If hard turning is performed on an open machine, there must be some form of guarding in place to protect the operator from the hot chips.

• Process—Because hard turning delivers the majority of cutting heat out in the chip, examining the chips during and after the cut will reveal whether or not the process is well-tuned. During a continuous cut, the chips should be blazing orange and flow off like a ribbon. If cooled chips essentially disintegrate when crunched by hand, then that demonstrates that the proper amount of heat is being carried out in the chip.

• White Layer—The infamous "white layer" can rear its ugly head in both hard turning and grinding operations. Invisible to the naked eye, it is a very thin (typically 1 micrometer) shell of material that is harder than the underlying material. If a white layer forms during hard turning, it is typically because a dull insert causes too much heat to be delivered into the part. It is most commonly formed on bearing steels and is most problematic for parts like bearing races that receive high contact stresses. Over time, the white layer can delaminate and lead to bearing failure.

Most bearing manufacturers have in-house testing resources to stay on top of this issue. For a shop just getting into hard turning, it is recommended that random tests be performed during the first few weeks of production to determine how many parts can be cut per insert without white layer formation. A metallurgical company can perform these tests. Even though an insert may be able to cut 400 parts within specification, it may be that it has dulled to the point where it causes a white layer after only 300 parts.

• Boring—The high cutting pressures involved in boring hardened material tend to multiply torsional and tangential forces on the boring bar. Cutting pressure can be reduced by using positive rake geometry and sharp 35- or 55-degree inserts with a small nose radius. Reducing the depth of cut and feed rate while increasing the cutting speed are other ways to reduce the pressure.

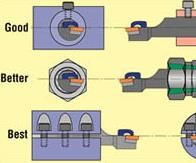

When boring, it is important to set the tool either on-center or slightly above part center, because cutting deflection lowers the effective centerline. The best clamping style is a full-length split sleeve, followed by collet-style and single point.

• Threading—Proper insert geometry is key for threading hardened materials. One of the best threading inserts is a triangular version similar to one that would be used on a boring bar. The 60-degree included angle and small nose radius work very well when threading at the right process parameters.

Additional passes and shallow depths of cut are necessary for threading hardened metals in order to keep cutting pressure down and extend insert life. Another alternative is to use an alternate flank infeed, which changes the cutting force locations and leads to longer tool life.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreRead Next

The Hidden Costs Of Cutting Tools

This shop brought the hidden costs down by paying close attention to tool inventory.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)