Grinding Machine Increases Tool Supplier’s Production

Komet of America Inc. had a problem: extra setup was causing a production bottleneck. Junker's Lean Selection allround grinding machine proved to be a cost-effective upgrade in technology that decreased setup times.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

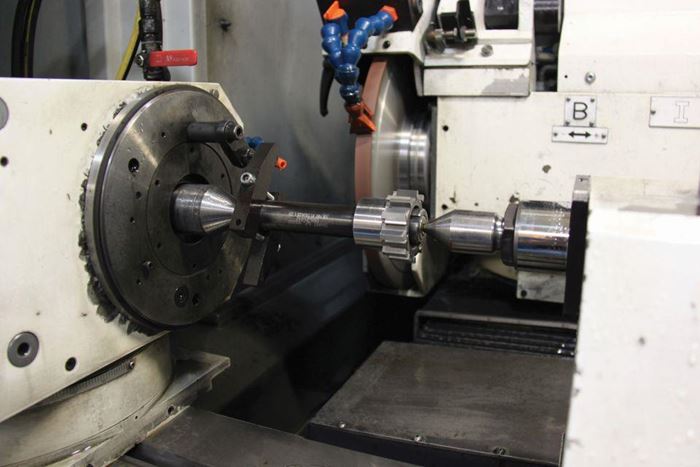

View MoreIn order to stay competitive in their industries, manufacturers must always be on the lookout for new ways to provide value while keeping cost to a minimum. That is one of the duties of David Zurowski, Dihart carbide group leader at Komet of America Inc. (Schaumburg, Illinois). When the company needed to produce complex tools at higher production rates, he knew its existing grinders could not keep up with the task. By investing in a universal cylindrical grinding machine from Junker (Elgin, Illinois), Komet was able to decrease production time while providing the same, high-quality products.

Established in 1918, the Komet Group is a full-line supplier of drilling, boring, reaming, threading and milling tools. With a total workforce of 1,600, the privately held company manufactures reamers, cutting rings and rapid-set heads with carbide and cermet blades. Led by President and CEO Jan Pflugfelder, Komet of America and its 140 employees are dedicated to the design and manufacturing of special indexable tools, polycrystalline diamond tools and reamers.

With a growing demand for complex tools, Komet needed to manufacture at higher production rates without sacrificing quality. The company determined that its existing grinders could no longer keep up with effectively producing its multi-step tools. In particular, tools with a flat diameter and back taper caused a major production bottleneck because the grinders required an extra setup to adjust the table to match the angle.

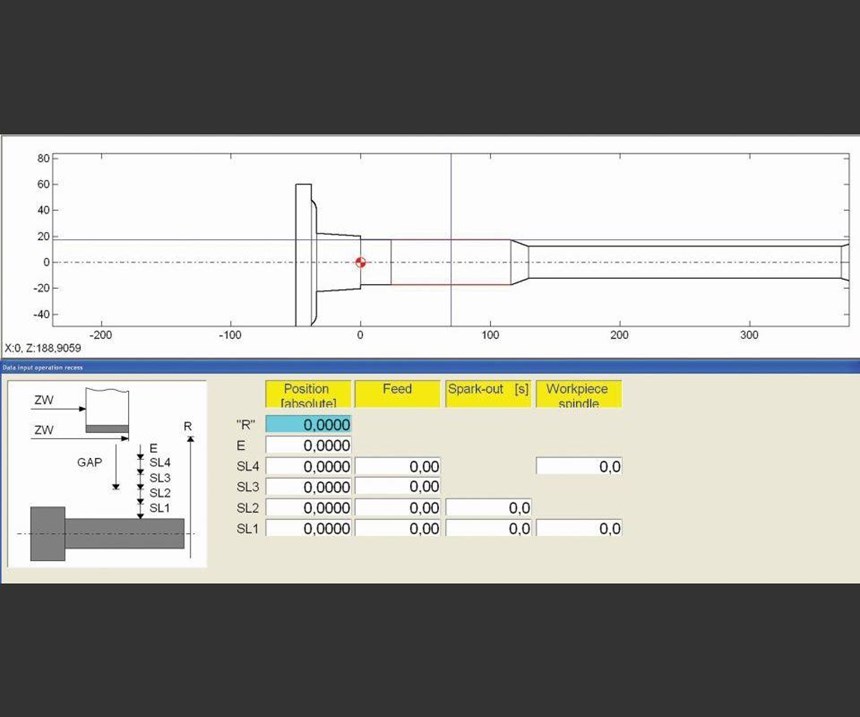

Komet began searching for a solution that would remove this extra setup as well as grind the tools in one clamping to simplify the process. Moreover, the company needed the grinding machine to be delivered in a short amount of time and to be able to accommodate a diamond grinding wheel. To meet these requirements, Komet searched for a CNC grinding machine with a freely programmable B axis that could accurately and efficiently grind parts. According to the company, Junker’s Lean Selection allround stood out because it offers a rigid B axis with 0.0001-degree resolution that is capable of grinding all the tapers Komet needs to manufacture its tools. Along with the crucial B axis, the flexibility of the grinding machine set Junker apart from the competition, the company says.

Mr. Zurowski says Komet selected a grinder with a choice of two grinding spindles because “we believe that we will have fewer limitations having one wheel per side and more clearance for our complex tools.” The machine was also available in a short delivery time and at an appealing price point, he says.

In addition to the proper mechanical features, the company sought a custom-designed grinding program to reduce the amount of air grinding. The carbide inserts ground on each reamer are set at common intervals along the diameter, meaning the grinding surface is interrupted. After several discussions about the problem, Junker suggested using its gap detection acoustic sensor to control the workhead speed. Now, when the grinding spindle detects air grinding, the workhead rotates quickly until the next carbide insert is detected. At each insert, the workhead slows to the “grind” setting then speeds up again to the “air” setting when finished grinding. This is designed to ensure the best cycle time.

In April 2015, the Junker Lean Selection allround arrived at Komet and was up and running shortly thereafter. With machine operation in full swing, the company immediately noticed significant savings in production times. Mr. Zurowski says that setting back the taper with the B axis has been easier, hassle-free and faster for operators. “In setup, we save around 30 to 35 minutes,” he says. The grinder’s flexible design not only provides significant savings in setup time, but it also reduced running time by 5 to 10 minutes per part. The freely programmable B axis enables the operator to grind continuously without having to change out the grinding wheel.

Despite the improved run time and setup time, Komet detected a final inefficiency after installation. Some parts required a wheel change in order to grind multiple features, making wheel-change time a critical factor in throughput. To improve change-over time and prevent potential quality issues when mounting a new wheel, the company implemented Junker’s three-point grinding wheel mounting system, which reduces wheel change-over times to less than 20 minutes and guarantees a wheel concentricity of less than 2 microns. Now that the system is installed, the company says it is experiencing a further reduction in setup times, improved grinding times and even better part quality.

“From our experience in grinding reamers and the way we set up and run the Junker, our finished product is the same quality despite a reduction in production time, which is what we were looking for,” Mr. Zurowski says.

Komet uses the same grinding wheels as it previously did, but the company says that setup is simpler, change-over is faster, and grind time is reduced. The machine is equipped with the JUWOP/LS programming system, in which the graphically supported data entry and to-scale representation on the screen are designed to make machine programming easy with little or no training.

Today, the company produces high-quality reamers with greater efficiency and at competitive costs for a quality/value proposition, Mr. Zurowski says. The economical and flexible Junker Lean Selection allround gives the tool supplier the freedom to manufacture a wide range of parts with high quality and precision as it aggressively seeks to expand its markets and provide new applications to its customers.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)