Flexible Fixturing Supports Automation

Robotics and carousel systems with custom fixtures help Akron-based Slice Mfg. Studios process hundreds of medical devices unattended.

Share

Slice Mfg. Studios in Akron, Ohio, is a contract manufacturer serving the medical and aerospace industries, among others. One of its specialties is 3D printing in metal—specifically, the manufacture of titanium medical implants with electron beam melting (EBM) which was the reason for my visit. Printing with EBM is tricky and can be dangerous; Slice’s success in using this technology has been the result of an intentionally designed facility, rigorous processes and ongoing knowledge building. Though the company also relies on machining, turning and EDM, additive manufacturing is clearly ingrained in Slice’s operations.

But it became apparent when I visited that Slice is also a believer in automation. Finish blasting of trabecular hip cups is performed by a FANUC LR Mate 200iD robotic arm inside a blast cabinet. Laser marking of parts is fully automated with a Foba M-series laser marking system. The company is talking about adding an automated guided vehicle (AGV) to shuttle parts around the facility, freeing operators from this task. And two of the company’s machining centers are equipped for unattended operation.

One of these, a Willemin-Macodel 508 MT machining center, has a robot and carousel system with rotating trays. The carousel can hold as many as 288 acetabular hip cups when these trays set up with corresponding 3D-printed fixtures (Figure 1). Before machining, the robot lifts each hip cup so that its diameter can be measured with a laser system. The part’s size is then relayed to the CNC to call the correct program for machining, enabling different part sizes to be loaded on the carousel at the same time. With automation, this machining center can process around 100 hip cups per day, more than the company’s EBM 3D printers can currently produce.

A newer machining center, a Willemin 508 MT2, features a lower turning turret that allows it to operate more like a Swiss-type lathe. This machine tool also has a more sophisticated automation system that uses a six-drawer carousel and FANUC 200 iD 7L robot equipped with vision capabilities for part identification.

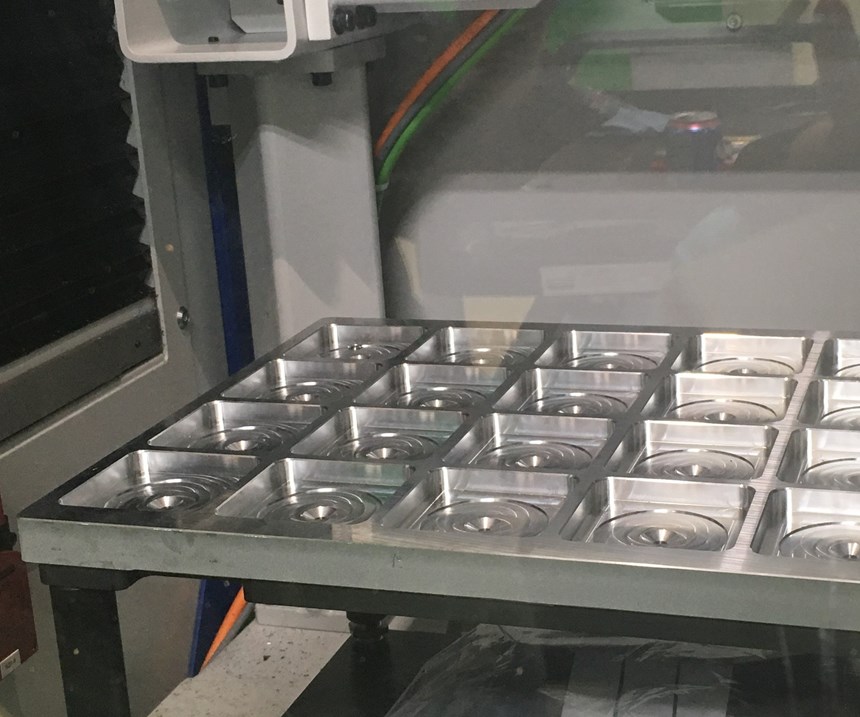

Slice has devised an interchangeable fixturing system for the 508 MT2: a machined tray with square holes (Figure 2). Plastic fixtures 3D-printed or machined to this footprint can be dropped inside to then hold the metal parts. To change the carousel over to accommodate a different part, the square fixtures can simply be lifted out and set aside.

Related Content

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)