Five-Axis Mold Making Software Keeps Tires Rolling

Unless it goes flat, a tire is something most of us take for granted. In fact, the process of making a tire is very specialized and is becoming more sophisticated all the time.

Share

Unless it goes flat, a tire is something most of us take for granted. In fact, the process of making a tire is very specialized and is becoming more sophisticated all the time. Matrix Tooling, Inc., (Bryan, Ohio) specializes in making complex patterns for the automotive industry on high speed three-axis CNC machines. As part of a growth plan to diversify and open new markets, Matrix sought after and won a contract from a major tire manufacturer. The contract involved making a set of molds that would be used to make tires for large diesel trucks.

Tire molds are typically cast from a ceramic mold. The cast molds are made by first create-ing a plaster pattern that represents the shape of the tire. A urethane-like material is then poured around the pattern to create what is known as a "toughy." Next, ceramic is poured around the toughy to form a mold. The toughy is then melted out of the ceramic. Finally, molten steel is poured into the ceramic to form a cast mold that will be used to make the tire.

While this method generally produces acceptable results, there are inevitably inaccuracies built into the mold. Matrix's customer wanted to improve the accuracy of its tires by machining certain critical surfaces on the cast mold. An example of this would be the area of the mold commonly referred to as "the road surface," which forms the portion of the tire that actually makes contact with the road.

The customer wanted to ensure that this surface was nearly perfectly round to increase the life of the tire and provide better performance. During the casting process, the road surface was left with an extra 0.040 inch of material to be machined off later. It was determined that a five-axis machine would be the most ideal way to perform this operation. In addition to improving accuracy, it was thought that the use of a five-axis machine would also reduce the number of required setups and machine time when compared to three-axis machining.

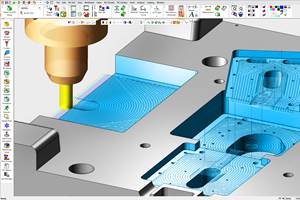

With this determined, Matrix had to overcome two problems: It needed a five-axis machine, and it needed a way to program this machine. Matrix was also on a very tight schedule. The company researched the machine tool market to find a machine that was suited for its application. It decided on the Mikron UPC 710 high speed machining center. With a machine on order, the company now needed five-axis programs. It initially thought of having the five-axis programming work contracted out, but because it was worried about lead time and quality, it decided to purchase its own sys-tem. Matrix found that there were only a few systems on the market capable of doing simultaneous five-axis contouring, and the company ultimately decided to purchase NCL multi-axis machining software from NCCS (Newport Beach, California).

NCL is a computer-aided manufacturing software package that generates simultaneous two- through five-axis NC tool paths and provides parametric 3D modeling. All geometric mod-eling and tool path functions are fully associative. A change to the model results in an immediate change to corresponding tool paths. NCL is suited for environments where design changes are frequent, such as the automotive industry.

NCL also supports full parametric pro-gramming where a family of parts can be machined by simply filling in a form. NCL is used extensively in the aerospace, turbo-machinery, power generation, tire mold and composite industries.

"We looked at three different CAM packages, and of those NCL seemed ideal for doing tire molds," says Gary Chmielewski of Matrix. "NCL was also recommended by other tire mold manu-facturers." To ensure immediate production, NCCS provided on-site technical assistance, including the provision of a postprocessor for the five-axis machine.

The mold is actually made up of nine separate pie-shaped segments, each a slightly different size. The manufacturing plan included five-axis roughing and finishing of the road surface and five-axis profiling around the edge of the tread walls. In addition, 115 vent holes per segment (for a total of 1,035 holes) were to be center drilled, drilled and reamed.

One week after the machine was delivered, programs had been generated and test cuts were being made. After determining the best cutter types and feeds and speeds to use, the NC pro-grams were optimized, and production machining began.

The company was pleased with the results. The roughing was done with a 1/4 inch by 0.02 inch corner radius bull nose end mill using a 0.125 inch stepover running at 14,000 rpm and 120 ipm. Finishing was accomplished using a 3/16 inch by 0.03 inch corner radius bull nose end mill using a 0.025 inch stepover running at 17,000 rpm and 120 ipm.

"Producing a similar finish on a three-axis machine would have required the use of a ball nose end mill using a stepover of about 0.002 inch or less and at much slower speeds," says Matrix CNC operator, Nathan Koppenhofer. "The utilization of a five-axis machine and the flexibility of the NCL software saved a conservatively estimated 15 hours of machine time per segment over conven-tional three-axis machining. Multiply this by nine segments, plus a total of four molds, and you have a time savings of 540 hours or 13 1/2 40-hour weeks. In addition to saving setup and machine time, we also achieved the desired accuracy with a 63 surface finish." Aside from these savings on the milling operations, there were additional savings on drilling and reaming.

Once the process was proven and the first mold was well into production, preparations for a second, larger mold were under way. With the parametric nature of the NCL software, the tool path from the first mold was easily applied to the geometry of the second mold. NC pro-grams were prepared very quickly, which ensured continued production on the five-axis machine.

Five-axis machining in the mold industry is still rare, but it is beginning to catch on, mainly because customers, just like Matrix, want shorter lead time and higher quality.

Related Content

For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;width=860)

.jpg;maxWidth=970;quality=90)