Quick Action Vises

Vises are the workhorses of workholding. With innovations like the Plumb multi-flex CNC, the ubiquitous vise will continue to evolve as a useful tool for metalworking shops.

The precision machine vise is the most popular workholding device found in metalworking. Vises are versatile and economical. In part because vises have been around for such a long time, many may think they are a mature product with much of their development potential already accomplished.

Well, think again. Development of the vise continues. Shops are looking to the machine vise for more and more of the workholding chores. As job lot sizes become smaller, the economics of investing in dedicated fixtures is less favorable. Moreover, shorter product life cycles, with more frequent engineering changes on the parts that must be cut, add to the need for more workholding flexibility.

All this is making the vise more popular than ever, and vise manufacturers have responded with innovations such as machinable jaws that can hold asymmetrical blanks. Other innovations include high-density workholders that use a minimum amount of the machining center worktable to hold a maximum amount of part blanks.

Quick action vises are another recent innovation to help shops achieve a key productivity goal—better throughput. Most vises are actuated when an operator torques a screw that is attached to a movable jaw. As the screw is turned, it presses the workpiece blank against a stationary jaw. On multiple setups, where more than one vise is used, cranking five, six or eight vises can take some time. And with the operator manning the crank, there can be a problem of consistent torque being applied. Unless the operator uses a torque wrench, over torque or under torque can affect machining consistency from workpiece blank to blank.

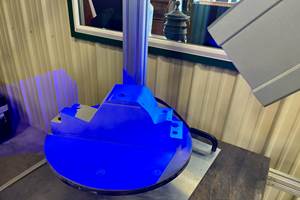

Plumb multi-flex CNC vises represent a new wrinkle on the torquing problem. Made by Woodbury Devices, Inc., (Woodbury, Connecticut) these quick clamping, multiple jaw vises use a short throw lever action to actuate the clamping of a workpiece blank. When the lever is up, the vise is unclamped. Push the lever down and the jaws close with an adjustable clamping force of up to 2,000 pounds. Once clamping force is set, it remains consistent from part to part and operator to operator.

The basic design of the Plumb vise uses a master jaw that is bolted directly to the center T-slot of a vertical machining center. Stationary jaws mount on the front and back to this master rail. The stationary jaws are made in one piece for better repeatability. Like the master rail they attach to, these jaws extend in the X-axis direction the full length of the multi-station vise.

Two hardened steel rods pass through the stationary and master jaws covering the machining center worktable in the Y-axis direction. The movable jaws attach on either end of the rods and are able to move freely on the rods. Once the movable jaws are in place, keepers are secured to the back end of the rod, and the actuation mechanism goes on the front end of the rod. At this point the vise is ready for a workpiece blank.

The relative positions of the movable jaws, end keepers and actuation mechanism are fully adjustable. When the workpiece blank is in place, these components clamp to the bar and the vise is ready to go. A simple adjustment of the components on the rod allows quick accommodation of different size workpiece blanks.

Vises are the workhorses of workholding. With innovations like the Plumb multi-flex CNC, the ubiquitous vise will continue to evolve as a useful tool for metalworking shops.

Related Content

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

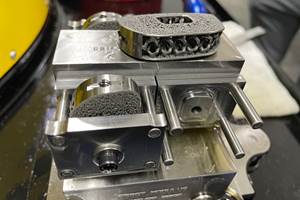

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreRead Next

The Automation Event for CNC Machine Shops

Get sensible, real-world automation solutions during this half-day workshop co-located with IMTS 2024.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreIMTS Elevate Workshop: Make Your Shop a Top Shop

This ½-day program offers attendees insight into the results from this year's Modern Machine Shop Top Shops annual benchmarking survey.

Read More

– Medium Rectangle (1).png;maxWidth=300;quality=90)