Employees and Automation in Harmony

For a well-known guitar maker, automation sets employees free, and product improvement engages those employees’ attention.

Share

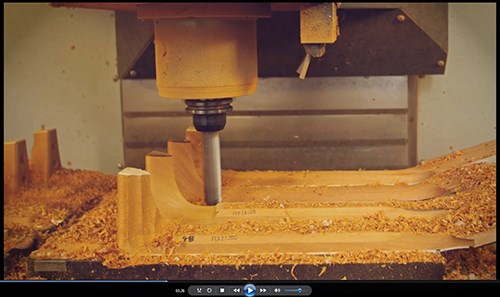

At Taylor Guitars’ production facility in El Cajon, California, the machining capability is mostly for machining wood. Some of the 27 CNC machining centers at this site produce metal tooling components used in the plant’s own production, but most of these machines precisely mill wooden guitar parts. This precision machining figures into a production process that also involves considerable artistic care and hand labor. The juxtaposition of automation and craftsmanship here provides a picture that might be relevant to understanding the proper role of automation in manufacturing in general. That is, automation does not replace people, but instead adds capability beyond what humans can do, and sets people free to give their attention to work that requires a human touch.

For example, Taylor uses robots. It uses various robots in varying operations throughout the process of making a guitar. One application is assembly. On the company’s Expression System 2 guitars, the pickup—the set of piezo-electric transducers that amplify sound—has been relocated from under the guitar bridge to behind it. That change improved sound quality, but made a layer of foil around piezo crystal difficult for human fingers to place, and impossible to place with consistency. Taylor’s response was a small Epson robot that now performs this assembly step reliably.

Meanwhile, at a much larger scale, a robot from ABB Robotics performs buffing. Unlike the pickup assembly, this is an operation employees can do and historically have done. But the work was difficult. Human strength would be used to hold the guitar box against the buffing wheel, an operation that was not only tiring but also intimidating to some and perhaps unsafe. The robot thus was used to automate an operation that employees generally did not want to do.

Yet the advance of the manufacturing process here is not always an advance into greater automation. This is significant. On the company’s new 800 series, the guitar’s improved acoustics result in part from a finish that is only one-half the thickness of the comparable finish on previous guitars. The challenge that finish presents is this: By what means can Taylor hold that finish within its new limits while still producing a guitar that is as pleasing to the eye as guitars with a heavier coating? The answer is manual labor. The guitar finish is hand-measured more frequently in production than previous guitars have been, and much more of its sanding is done by hand. And part of the reason why the company had the labor capacity to implement these changes is because of the way it has used automation to free up labor from less rewarding tasks such as buffing.

The lesson in this is bigger than transducers or wood finishing, and bigger than guitars. At Taylor, automation extends and liberates employees’ capabilities, while the employees stay. The company has made the promise that no employee will be laid off because of automation. This has been an easy promise to keep, because Taylor needs the people. Indeed, it needs to automate even further in order to keep setting employees free, because an ever-advancing company that is continually improving its product line is continually finding new challenges that call for the focused attention of talented people.

Related Content

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More