EDM Economizes Stamping Tool Production

High part volumes tend to be the norm for providers of stamping services, but the nearly 1 billion electrical contact connectors produced last year at Scenic Tool and Stamping aren’t such typical fare.

Share

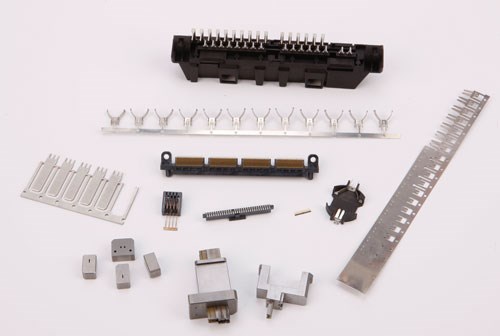

High part volumes tend to be the norm for providers of stamping services, but the nearly 1 billion electrical contact connectors produced last year at Scenic Tool and Stamping aren’t such typical fare. Measuring approximately 0.03 inch wide and 0.15 inch long, these components often have features as small as 0.012 inch and require holding overall dimensional tolerances within ±0.0005 inch. Competitiveness depends on not only meeting the stringent accuracy and surface finish requirements of the intricate tooling used to stamp these components, but also keeping processing times for that tooling to a minimum. Wire EDM technology from GF AgieCharmilles (Lincolnshire, Illinois) is critical to achieving both goals, says Mike Blackwell, president of Scenic Tool and Stamping. “Wire EDM is at the heart of our shop,” he says. “We design tooling according to the capabilities of that technology.”

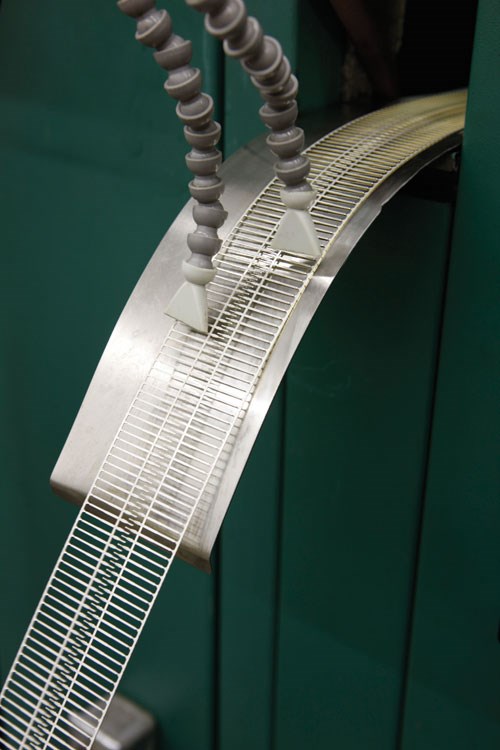

Founded in 1995, Scenic Tool and Stamping is a family-owned, 30-employee supplier of stamped products and tooling and provider of tooling repair and design services that operates out of two buildings in Cordobella, South Carolina. Although the company takes on a range of job sizes, it specializes in small, complex components like the electrical contact connectors and the tooling used to produce them. Approximately 90 percent of the connectors run reel-to-reel in lot sizes ranging from 50 parts to millions. Raw material—typically copper, beryllium, stainless steel or brass—moves on coils through progressive stamping presses that run at speeds as fast as 1,000 to 1,200 strokes per minute to stamp the parts in rapid succession. After inspection and quality testing, the material is re-wound onto a reel and shipped, either for outside plating services or directly to the shop’s mostly electronic and automotive industry customers.

Producing these tiny, complex connectors to exacting tolerances isn’t expected to get any easier. As consumer products continue to shrink, the components inside them do as well, and the shop reports that this trend has been leading customers to request even smaller connector designs. In turn, the tooling used to stamp these components must also be smaller and more precise. Nonetheless, Mr. Blackwell remains undaunted, thanks in large part to the capabilities of the shop’s GF AgieCharmilles Cut 2000 wire EDM. “With the ability to cut parts using wire diameters as small as 0.002 inch, we are able to easily meet requirements for smaller, more precise micro-stamping tooling,” he says. “More importantly, the machine enables us to generate the extremely high-quality surface finishes that are critical for that tooling.”

The Cut 2000 is capable of achieving surface finishes as smooth as 0.2 Ra, says Eric Blackwell, CNC and EDM manager. Moreover, the necessary settings and parameters for achieving such finishes are built into the machine’s control. This eliminates the need for time-consuming, trial-and-error adjustments. Other notable machine features include GF AgieCharmilles’ Intelligent Power Generator (IPG), which is said to provide reliable machining of complex parts with stringent surface finish requirements, and a cast iron, C-frame construction for stability and dynamic rigidity.

The machine’s automatic wire changing (AWC) capability is also critical for Scenic Tool and Stamping to minimize processing times for tooling and to conserve its higher-end, smaller diameter wire, says Eric Blackwell, the shop’s CNC and EDM manager. Any given tooling component might require as many as 20 different small cavities, many of which contain tight radii. These features are ideally suited for the shop’s small-diameter wire, which consists exclusively of zinc-coated, steel-core material with high tensile strength from GF AgieCharmilles. This wire is less suitable for roughing, but the time required to swap wire often left the shop with no other economical choice prior to installing the Cut 2000. For example, it once machined a series of 1.75-inch-thick carbide punches using only 0.004-inch-diameter coated wire. Now, however, it can rough the parts much faster using 0.008-inch-diameter brass wire and automatically change to smaller-diameter, coated wire for finishing.

In operation, two spools at the back of the machine feed wire to two corresponding brake mechanisms at the front of the machine. After the first wire is cut, one brake mechanism rotates out of the way, and the other rotates into place to enable automatic threading of the second wire from the other spool. At the heart of the system is GF AgieCharmilles’ Universal Wire Guide technology. Both the upper and lower wire guides feature a three-point, roughly V-shaped design. As opposed to systems that require threading a specific wire size through a hole, often with very little clearance, this construction enables wires ranging from 0.002 to 0.012 inch to nestle snugly within the slot created by the guide’s V shape, the company says. The current contact that charges the wire also serves to secure it within this V slot. During a change, the current contact moves out of the way to enable a new wire type or diameter to slide into place.

With this technology, automatic wire changes take less than 2 minutes, Eric Blackwell says. He adds that the system always “knows” the exact center location of its V-guides. Operators simply enter the desired wire diameter size into the machine’s control, and the guides compensate for the difference between one wire diameter and the next. More importantly, the machine tracks wire center to maintain exact part location and size after a wire change.

Since its founding, Scenic Tool and Stamping has never experienced a true slow-down, the Blackwells report. Thanks in part to EDM technology from GF AgieCharmilles, they expect that trend to continue in coming years as the shop expands into the medical and aerospace industries.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)