Allied Machine Drill System Provides Enhanced Chip Evacuation

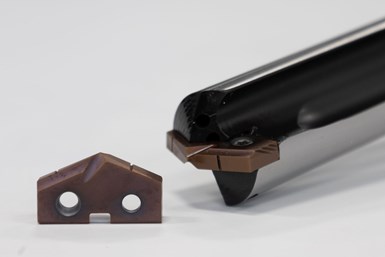

Eastec 2023: The T-A Pro drill body incorporates straight flutes designed for optimized coolant flow and rigidity.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Allied Machine and Engineering, a leading manufacturer of holemaking and finishing cutting tools for the metal-cutting industry, is showcasing the T-A Pro at Eastec 2023 in booth 5453. The T-A Pro drilling system is said to provide extended tool life, consistently create quality holes and deliver superior chip evacuation even in the toughest applications.

The T-A Pro drill body incorporates straight flutes designed for maximum coolant flow and excellent rigidity while the material-specific insert geometries produce optimal chip formation. These insert geometries include steel (P) with AM300 coating; cast iron (K) with TiAIN coating; nonferrous (N) with TiCN coating; stainless steel (M) with AM460 coating; and high-speed steel substrate (X) with AM200 coating.

Adding to the material-specific inserts available for the T-A Pro, Allied most recently launched the new M geometry insert with AM460 coating, which targets stainless steel and heat-resistant super alloy (HRSA) materials. With the release of the M geometry and its proprietary margin design, Allied is able to provide a tool that reportedly offers low cutting forces, excellent penetration rates and long tool life in challenging stainless and HRSA materials. The new insert geometry features newly designed T-A Pro holders, but is also compatible with T-A holders.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

.png;maxWidth=300;quality=90)