Difficult Materials Are No Match for Ceramic Inserts

TNG Energy Services Inc. was experiencing inconsistent carbide insert life in valve grooving applications. Greenleaf's Ring Max and face grooving tooling helped to reduce production time and increase reliability.

Share

While manufacturing parts just in time (JIT) has many advantages for a shop’s customer, shops oftentimes face challenges with this sort of production schedule. Namely, there’s no wiggle room for meeting deadlines.

This was especially true for TNG Energy Services Inc., a geothermal company that provides both equipment and services from its Bakersfield, California, headquarters. The company’s mostly JIT workload along with meeting strict quality control requirements led its employees to work large amounts of overtime. This was due, in large part, to the challenges of machining grooves in valve components for oilfield applications using conventional carbide inserts. By switching to ceramic inserts from Greenleaf Corp. (Saegertown, Pennsylvania), TNG was able to dramatically reduce cycle time for two valve applications, meeting deadlines without the additional overtime costs.

Before switching to ceramics, TNG used carbide inserts to produce two API ring grooves on 31/8-inch-diameter valve bodies with a 1963 manual-engine lathe, a process that took between 10 and 15 minutes each to complete. The real challenge, though, was in reconditioning these valve bodies, because it often required cutting through difficult-to-machine materials such as Inconel. For instance, after opening the grooves in the cast steel base material 3/16-inch larger than the API specifications, the valve went to the welding department for Inconel cladding. From there, the process involved opening a straight face groove with a face grooving tool followed by an API ring groove tool. This was only possible by moving into the cut 0.100-inch axially, then moving in a positive and negative radial direction to the groove’s full width. After that, the machinist would move the tool in another 0.050 inch and blend from side to side to match the width of the previous radial cut. These tiny increments were repeated until the full depth of cut was reached. An experienced, efficient machinist like TNG’s lead machinist, Cimaron Hylton, could produce one groove in about 45 minutes, though many days it took closer to an hour.

According to Mr. Hylton, taking such small depths of cut was necessary to reduce vibration and chatter, yet it didn’t fully eliminate it. Several times during the grooving process, machinists had to check the pitch diameter to ensure accuracy. They also had to hand-polish the angled groove walls.

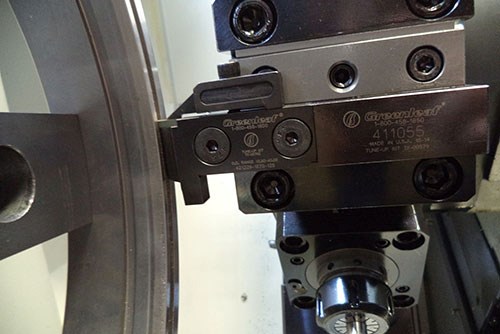

Spurred by often unpredictable tool life and lengthy production times, TNG turned to ceramic inserts from Greenleaf. In the ring groove application, the company decided to use the Ring Max API ring groove cutter with WG-300 whisker-reinforced ceramic inserts. Designed specifically for the oil and gas industry, Greenleaf’s Ring Max line of ring groove tooling is engineered to reduce the machining time of API ring grooves, while the basic concept of WG-300 involves reinforcing a hard ceramic matrix with extremely strong, stiff, silicon-carbide crystals, or “whiskers.” The whiskers are dispersed into a matrix of fine-grained aluminum oxide, where they act much like glass filaments do in fiberglass, for example, by adding tensile strength and improving the fracture toughness of the brittle matrix.

Although WG-300 is designed for excellent shock and wear resistance at high surface speeds for nickel- and cobalt-based superalloys, the grade is a good match for TNG’s application, which runs the materials at a relatively modest horsepower rating (20 hp) on its Hwacheon Vesta 1050B CNC mill.

The ceramic inserts really show their colors during the reconditioning applications, Mr. Hylton says. After the Inconel cladding is applied, he mills down the weld that’s bulging above the flange and follows up with the Ring Max tool, cutting the ring groove in just 28 seconds. Because ring groove machining is a continuous cut, through-spindle coolant is used. The coolant is used not to cool the insert, but to cause the chips to become more brittle and break into smaller pieces, sometimes becoming almost powder-like.

TNG also uses ceramic inserts on its bread and butter work of cutting valve seats in 410 stainless with a Stellite overlay. According to Mr. Hylton, this application is tricky because the groove goes through the Stellite, then through the heat-affected zone and down to the base material—an application that requires cutting material ranging from 40 to 67 HRC.

With the carbide inserts, Mr. Hylton says he had to peck at 0.005-inch depth increments to keep any edge at all. In addition, the retract amount that was programmed into the peck cycle had to be larger than usual due to tremendous amounts of tool pressure. In this case, the actual surface of the cutting tool/workpiece interface was 0.010-inch farther out than the actual machine position. The need to have a 0.012-inch buffer between pecks increased the actual feed travel to 1.498 inches. This meant the machine had to feed a total of six times the actual depth of the groove. The slow nature of this process was exacerbated by the need to peck.

Another problem was the machine’s low speed. It simply didn’t have the torque necessary to efficiently machine all layers of the material, and it would rumble and beat everything up, Mr. Hylton says. He often used three carbide insert tips during the process, requiring him to stop, pull the insert, change it and hit cycle start again. The entire grooving process took between 47 minutes to an hour to complete. To make matters worse, Mr. Hylton says that sometimes the insert would break randomly; there was no consistency at all.

Now, the company uses a face grooving tool with Greenleaf’s new Xsytin-1 ceramic inserts and a support blade. According to Greenleaf, Xsytin-1 is a phase-toughened ceramic insert grade that is showing promise for a wider range of materials than traditional ceramic insert technology, bridging the gap between conventional carbide and ceramic inserts for exotic materials, as well as more conventional metals such as mild and stainless steels. The company says its proprietary phase-toughening ceramic manufacturing process developed for this coating-free grade results in predictable, wear- and thermal-shock-resistant inserts that are twice as strong as the company’s WG-300 whisker grade. It also enables the generation of a sharper insert edge, which can lead to reduced tool pressure and better surface finishes.

The groove is produced in one shot, eliminating the finish pass as well. When TNG started using the ceramic face grooving tool, Mr. Hylton says he was nervous. He questioned his Greenleaf representative about his suggested cutting speeds. However, he says his fears were soon calmed when he saw the Stellite coming off like powder. The ceramic face grooving tool can cut the groove in 30 to 40 seconds.

Now, Mr. Hylton says the problem is the base material. “Before, I couldn’t wait to get there,” he says. “Now, when I hit the stainless, the chips come off in long strings. The inserts get a little beat up on the sides from the chips because face grooving is a nasty operation.”

Mr. Hylton says he’s noticed the Xsytin-1 grade shows significantly less damage when the groove is complete, so he plans to transition the Ring Max application to the new insert grade once he runs through his batch of WG-300.

While the ceramic inserts could potentially be used for more than one groove, he says that he changes them after each groove to be on the safe side. But even at one groove per insert, he says he’s impressed with the predictability and longevity of the ceramic inserts. In fact, he’s quit trying to push tool life in the face grooving operation because the ceramic inserts are comparable in price to the carbide inserts when time savings are factored in.

Given the productivity gains for just one valve feature, Mr. Hylton has no question about moving forward using ceramic inserts. TNG is even planning on producing two valves per week in the future because of these improvements.

“One little insert has made a big difference,” Mr. Hylton says.

Related Content

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)