Desktop 3D Printer as Job Shop Resource

The low-cost 3D printer in this shop supports machining by simplifying prototyping and producing usable hardware—including vise jaws.

Share

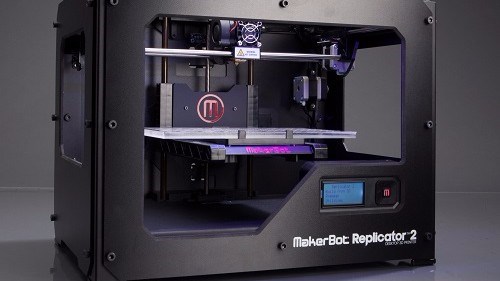

Will consumer 3D printers one day become commonplace in our homes? Maybe yes, maybe no. In the meantime, will these same low-cost 3D printers become commonplace in CNC machining job shops? If the example of Kenworthy Machine of Duvall, Washington is any indication, the answer is yes. The shop bought a MakerBot Replicator 2 desktop 3D printer as an aid to prototyping, but continues to find uses for it that go well beyond this. Recently, the shop 3D printed custom vise jaws for a job on a vertical machining center.

“Once you have this capability, you think about problems differently,” says Mark Kenworthy, the shop’s owner. “New possibilities present themselves.”

Mr. Kenworthy is a former program manager at Microsoft who had always been fascinated with manufacturing. He founded the shop after leaving the software company 10 years ago. Today, the shop employs six, who oversee resources including five vertical machining centers and two CNC lathes, the latest of which is a bar-fed nine-axis lathe from Ganesh. The 3D printer was purchased specifically to spare these machines from having to run jobs that are not yet ready for production.

He explains, “When it comes to part design, we have various types of customers.” Some, particularly large OEMs, have their designs nailed down before the jobs ever come to him. But others, particularly inventors, at best know what they want their components to do, but they need to hold and evaluate the physical part before they can confirm that it matches their expectations.

Of course, any job shop knows the problem with this. “I often can’t afford to program and set up the CNC machine if there is only one piece involved,” Mr. Kenworthy says. Enter the MakerBot. While this machine is not as precise as a CNC machine tool, it generally can deliver a representation accurate enough to let the customer validate the part’s design.

In other words, the 3D printer is a design resource rather than a manufacturing one. And this highlights one reason why the possilibities for consumer 3D printing are questionable. The capability of the printer is entirely determined by the user’s CAD capability, and even a home user who has CAD likely doesn’t have proficiency with it. By contrast, the printer is a natural complement to the resources many job shops use. Mr. Kenworthy’s shop has SolidWorks and he uses it every day. To him, the printer is an extension of this software—a way to turn the digital designs into tangible forms.

And yet, the applications for the printer also have advanced well beyond design models. This advance began simply. A display case needed shelf brackets. The shop owner designed and printed them. A kitchenette connected to the shop lacked a good place to store eating utensils, so Mr. Kenworthy designed and printed a wall rack. (He also posted this design to the website Thingiverse, from which hundreds have downloaded it.) And when a button broke on the CNC panel of an older machine tool, he printed a replacement button and added the necessary electronic closure to it to put that machine back into use.

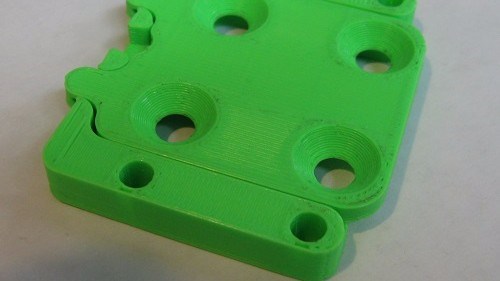

The vise jaws have so far been the largest and most critical functional component the shop has made on the small printer. The jaws provided an inexpensive solution to what otherwise might have been a costly workholding challenge for the shop, which lacks indexing capability on its VMCs. A component of a winch assembly featured two opposing holes, each drilled at approximately a 30-degree angle to the part’s longest dimension. Rather than engineering a custom fixture for these holes out in the shop, Mr. Kenworthy designed jaws in SolidWorks to hold two pieces in one fixturing at the angle needed. He was even able to include the fixture ID number in this printable CAD design, saving an engraving step. The 3D printer generated these forms in builds that took 24 hours for the larger jaw and 14 hours for the smaller one. Those may sound like long cycles, he says, but he points out that printer runs unattended. Twenty-four hours is therefore just one day, not three different shifts.

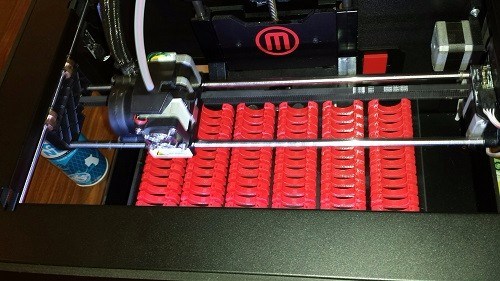

To improve the ability to make functional components on the printer, the shop owner has modified it. The standard build plate did not provide sufficient flatness for printing large parts or arrays of parts, he says, so he replaced it with a flat borosilicate glass plate bought from an aftermarket vendor. Now, the flatness is tight enough that the machine can be used to make an array of functional parts that fills the entire build area, the shop owners says.

He knows this from experience. Lately, in addition to workholding, the printer has made workpieces. These are not customer’s critical parts, but parts related to a side business. Mr. Kenworthy is active in robot competitions that aim to instill in young people the same love of manufacturing that he enjoys, and he has developed and begun to market a line of low-cost robot chassis that can make it more affordable for schools to bring robotics to their students. The desktop printer has been busy recently on making various plastic components that go into these robot bases.

Related Content

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More