Deep Holes with a Carbide Microdrill That Flexes

These microdrills combine the advantages of HSS with those of solid carbide.

Share

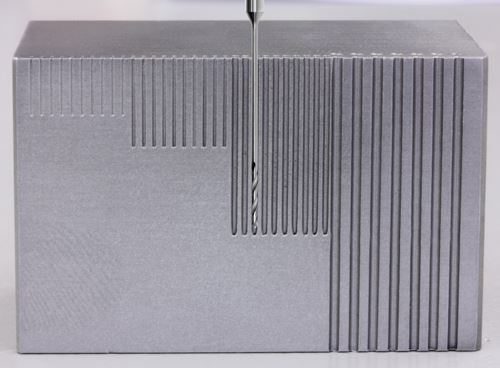

The microdrills in the CrazyDrill Flex line from Mikron Tool (Monroe, Connecticut) are designed to combine the advantages of HSS (flexibility and resistance to breakage) with those of solid carbide (precision and resistance to wear). This combination makes the drills reliable in difficult drilling situations yet very productive in holemaking capability. The Flex line covers diameters ranging from 0.1 to 1.2 mm in 0.01-mm increments. Two length categories are available for holes as deep as 20 times diameter or 30 times diameter.

According to the company, the drill’s unusual flexibility is attributable to two factors. For one, the drills are made of a new carbide alloy that is engineered to have mechanical properties that make it less brittle than other carbides and more like HSS in terms of what the company calls elasticity. For another, the geometry of the drill includes an extended neck with a reduced cross section between the shank and the fluted cutter head. As a result of these engineering concepts, the Flex drill is slightly bendable. It can flex from 0.1 to 0.6 mm from center, depending on the overall length of the neck.

Furthermore, the carbide alloy retains the wear resistance and hardness of typical carbides, the company says. This enables the drills to remove material faster than HSS and last longer before dulling. In addition, a 140-degree point angle and wide flutes aid chip breakage and evacuation. Smooth chip flow also reduces cutting forces such as torque and feed force. This geometry is also said to prevent stringy chips from wrapping around the neck or shank.

Having HSS-like flexibility and carbide-like wear resistance makes the Flex drills suitable for situations in which holemaking equipment offers less-than-precise drill positioning. Positioning error can be caused by misalignment in the rotary indexing tables of transfer machines, the spindle drums of a multispindle lathe or drill stations in a series. Thermal expansion on a machining center can also cause misalignment. In any of these cases, the drill’s slight flex can compensate for misalignment, thus preventing excessive side forces from snapping the tool. The resulting reliability of the microdrill and its capacity for high drilling speed makes it useful for lights-out or lightly attended operations, the company says.

According to the company, the performance of these drills makes holemaking operations on these machines competitive with small-hole EDM (electrical discharge machining) and laser drilling. The company reported a test cut involving 10 holes measuring 0.5 mm in diameter and 15 mm deep. The Flex drill took 3 minutes to perform the operation versus 24.4 minutes for gundrilling and 30 minutes for EDM.

However, using this type of microdrill may require a change in CNC holemaking routines. Drills in diameter sizes at the low end must have a pilot hole produced by a CrazyDrill Flex Pilot drill of the same diameter. The pilot hole, which works best at three times the drill diameter, centers the Flex drill and stabilizes as it as it enters. Also, while holes as deep as seven times diameter can be produced in one step, drilling deeper holes (as deep as 30 times diameter) requires additional pecking cycles.

These microdrills have been used successfully to drill deep holes in aluminum, brass, copper and steel. The company reports the main applications to be micromachining of precision parts in the watch and medical industries or for machining fuel injection components.

Related Content

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More