Cutting Gears with Multitasking Machines

Multitasking machines provide an excellent point of entry for machine shops interested in adding gear manufacturing to their list of capabilities, including power skiving.

Share

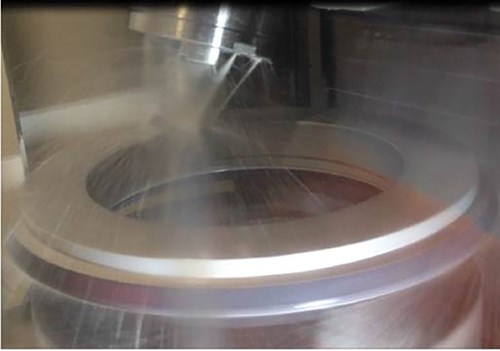

Today’s multitasking machines continue to command a presence in the world of gear cutting as viable processing alternatives for low-to medium-volume production. What started with five-axis cutting of larger-diameter ring gear sets has now ratcheted up to power skiving gears using the highly synchronized rotation of a multi-tasking machine’s milling spindle and C axis.

Unlike high-volume dedicated skiving systems, multitasking machines provide the flexibility to perform other part operations. For instance, shops can turn a part’s ID and OD as well as cut its other mating features, and all on the same machine that will also power skive the part’s gear tooth pattern. This significantly improves overall part accuracy because all the machined features run true to the gear teeth. Plus, the same multitasking machine that power skives a gear one day can machine completely different, non-geared components the next.

The Power Skiving Process

Dedicated skiving systems are fast, but multitasking machines are much more cost-effective in comparison, especially when they eliminate the need to farm out occasional gear work. By keeping gear cutting in-house, shops also gain complete control over part processing, as well as delivery times, because outside vendor turnaround times are no longer an issue.

Prior to its power skiving applications development, Mazak showed how larger sized five-axis multitasking vertical machining centers could cost-effectively and quickly produce those occasional, low-volume spiral bevel gear sets in-house. Mazak machined a spiral bevel gear set that included a 29-tooth, 22"-diameter pinion gear and a 114-tooth, 6-foot-diameter ring gear on one of its Integrex e-1550V/10 multitasking five-axis machining centers. This gear set was completed in days as opposed to months, and using only the one machine.

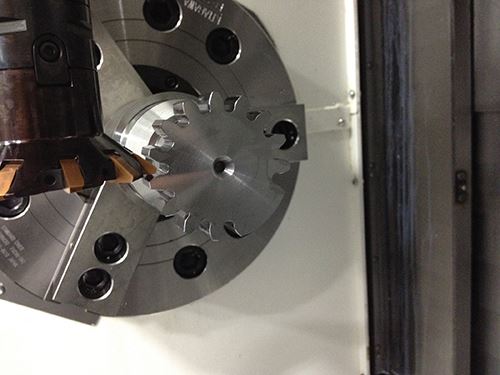

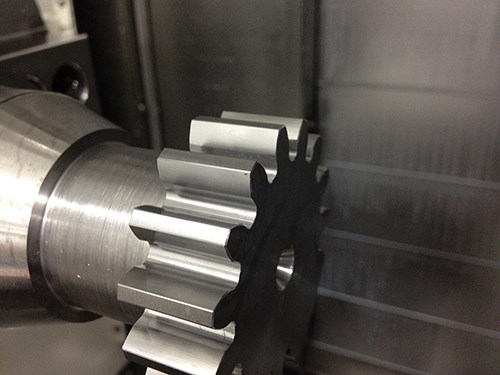

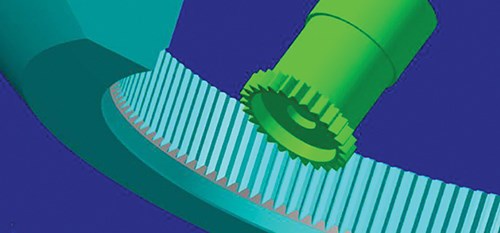

Power skiving is a gear shaping process in which cutting tools are shaped like gear teeth. The tools spin and mesh with workpieces to generate the gear teeth geometry, and it is this meshing that creates the gear teeth profiles.

For its skiving process development, Mazak also used Integrex series multitasking machines. The models included the e-420 and i-200, both with B-axis milling spindles and C-axis turning spindles, and the Integrex i-630 with a B-axis milling spindle and C-axis table. The machines successfully power skived gears of all sizes and types, including standard and ID splines in both straight and angled teeth patterns. These machines could also power skive spur gears or helical gears.

Seeking Synchronicity

Synchronization and proper cutting ratio are key in power skiving. During the operation, the workpiece—whether mounted on a table or in a turning spindle—rotates in synchronization with that of the skiving tool. Rotation of the two also happens at a specific ratio dictated by the number of teeth being cut in the part and the number of teeth on the cutter itself.

The power skiving operation is a precarious and parameter-specific process in that there is very little room for error. As both the workpiece and cutter masses spin, the slightest miscalculation in terms of synchronization will immediately cause chatter that will continue until the cutter is completely removed from the cut and adjustments are made.

There can be limitations in terms of rpm—how fast the C axis can spin while maintaining proper synchronization with the milling spindle—with traditional gear cutting processes. Dedicated skiving machines typically offer higher synchronized-rpm capabilities. However, with its new Mazatrik SmoothX CNC control technology, Mazak continues to boost the speeds/rpms at which its multitasking machines maintain skiving synchronization. Synchronization at faster rpms helps shorten power skiving cycle times and allows the machine to cut a wider range of gear sizes.

Another aspect of power skiving is that workpieces rotate faster than in a hobbing operation. Consider, for instance, a 40-tooth gear would rotate at 8.75 rpm while using a single start hob rotating at 350 rpm. To power skive the same gear, the part would need to rotate at 218.75 rpm while using a 25-tooth cutter rotating at 350 rpm.

To produce the necessary speed and accuracy, multitasking machines intended for power skiving gears must have integral motor C axes. Those that are gear driven are unable to achieve high enough rpm and, simply by the nature of their design, allow for too much play. Power skiving also requires a very rigid cutting tool-spindle interface with absolutely zero rotational play. If the tool moves at all, the result will be vibration that, again, will continue until the tool is completely removed from the cut.

Skiving tools, like gear hobbers, progressively generate all the gear teeth profiles on a part simultaneously, as compared with machining each tooth individually with a standard milling cutter. However, there are clearance requirements that must be met for power skiving tools. The intended gear pattern location should be such that it allows for interference-free machining. The machine’s spindle needs plenty of room to tilt—almost to a horizontal orientation between 7 and 15 degrees—and maneuver the skiving tool for cutting.

Basically, the gear patterns must be close enough to the workpiece ends to provide ample room for either OD or ID power skiving. Consider a 20"-long shaft part with a gear pattern at its center. This means that 10" of the part would interfere with the machine’s milling spindle, and the gears would have to be hobbed or machined with special disc mill-type, flat-bottomed cutters.

Those particular cutting tools, similar in appearance to slotting cutters, typically have 10 or 12 inserts and cut gear teeth profiles one at a time. The tools provide the flexibility to produce a range of diametral gear pitches, which is especially applicable to prototyping and producing very low gear volumes. A power skiving tool, on the other hand, generates multiple teeth for a particular diametral pitch gear. However, the power skiving process is much faster.

Adding Capabilities Economically

Regardless of the tooling and processes used, interest continues to grow in cutting gears on multitasking machines. And many shops involved in key industries such as heavy equipment, motorsports and others currently benefit from doing so for their low- to medium-volume gear production. Others that benefit are shops that want to bring gear cutting back in-house, and those that are simply unable to justify the cost of replacing worn out existing pieces of dedicated gear cutting equipment. But, it should be noted that dedicated gear cutting equipment is not going away. Multitasking machines simply provide another option for machine shops doing smaller batches of gear cutting in addition to other part-processing operations.

Related Content

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreWFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreControlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More