Continuous Improvement Efforts Lead to New Tooling

G&G Machine’s continuous improvement journey led it to adopt a lean philosophy as well as add new MultiTap tools from Emuge to reduce tooling inventory.

Share

In 2007, G&G Machine ran out of space in its 40-plus-employee shop in Kaukauna, Wisconsin. Turning to the Wisconsin Manufacturer’s Extension Partnership (WMEP) for consultation, the company learned that a new plant layout along with a lean manufacturing philosophy and 5S workplace organization would be key to making more space. The company also realized that it needed to take a critical look at its overall machining strategy, specifically its tooling, to enable continuous improvement in its production efforts.

“After all the analysis, we discovered 150 tons of material we didn’t need,” explains Mark Stumpf, president. “We also found room to add a weld shop and install larger, more efficient machines in space we didn’t know we had,” he says. Once G&G made it past the initial 5S push, the company implemented other lean tools, such as value stream maps, to reduce lead time and improve overall equipment effectiveness measures to keep spindles turning. “We wanted to see just how much we could wring out of our current shop before building a new one,” he says.

It took two years to implement the lean strategy, during which time the company was able to grow. This finally led to the construction of a new 30,000-square-foot manufacturing facility that houses three multi-axis lathes, five two-axis lathes, three HMCs, four VMCs, one Zeiss G2 CMM and a clean room. During the lean implementation, the company also adopted a new vendor-managed inventory auto crib system. The tooling dispenser unit eliminates the need for multiple people to manage tooling, explains John Fiers, tooling supervisor. It also saves time and money on stocking and restocking tools, he says.

G&G serves many different market segments with various material requests. Typical applications for metals range from common carbon steel, aluminum, brass and bronze, to such exotics as titanium, Hastelloy, Waspaloy, Zeron 100, Monel and super alloys. When machining expensive materials such as these, breaking a tap, or any tool for that matter, is not an option. The company routinely manufactures high-accuracy parts—to tenths and below. It also manufactures pumps, valves and rotating parts for the oil and gas industry and impellers for the energy industry. Other markets served include food processing, power transmission, petrochemical and railroad.

Tapping into Lean Production

To reduce waste and work smarter, the company began evaluating its tooling. During this process, G&G determined that it needed to find a tap or thread mill that would not break in a variety of applications—from the basics to exotic alloys. The company also sought to decrease its tooling inventory and suppliers, as well as change-over time.

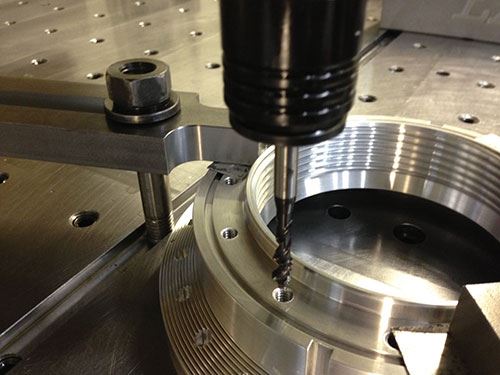

G&G had been using a variety of different taps for a wide range of applications. Machinists found it difficult to know which tap was best for a given application. Because of these issues, taps failed often, leading to machine downtime, scrapped parts, rework and considerable amounts of frustration—all of which cost time and money. By incorporating the MultiTap from Emuge (West Boylston, Massachusetts) into its manufacturing process, the company was able to reduce machine downtime and rework.

New Taps Save Time and Money

In search of a way to improve the tapping process, Chris Weaver, value stream manager, says the shop tried using Emuge tools. “We were impressed by the feeds and speeds recommended. However, we wanted to be sure there were no issues with tap breakage, which we had experienced on other tap brands,” he explains. The company tested different Emuge taps, including the MultiTap, over a couple of months with great results, he says. There was less downtime, no rework and no broken taps. “Being able to run the taps faster with less replacement has provided a significant savings,” he says. Mr. Weaver cites an example in which the company drilled a hole 1/16-inch undersize and threaded it with the MultiTap. “Much to our amazement, the tap held up fine without breakage,” he says.

The MultiTap is constructed of a proprietary grade of high speed steel (HHS-E) that is nitrided with an Ne2 surface treatment. Emuge’s taps are made with long shanks—specifically, DIN length for extra reach. UNC and UNF taps are DIN length with ANSI shanks, while metric taps are DIN length with DIN shanks. A full range of tap sizes for UNC and UNF threads is available with inch sizes ranging from 4-40 to ¾-16 and metric sizes ranging from M 4×0.7 to M 16×2.0. The high-performance, general-purpose taps are designed to produce threads within both 2B and 3B classes of fit. According to Emuge, the MultiTap is well-suited for short- and medium-run threading applications in a wide variety of materials, including carbon steel, steel alloys, stainless steel, aluminum, cast iron, copper, brass and bronze.

The tap’s ability to handle most common materials and applications with increased thread quality helps lower production costs, Emuge says. For instance, when G&G required certain taps for specific applications, it spent a lot of time and money managing tool inventory. Once it began using the MultiTap, it was able to reduce the number of taps stocked in the tool crib because each MultiTap does the work of several other taps. According to Mr. Stumpf, the company has seen a 20-percent cost reduction in taps due to the MultiTap’s versatility.

While G&G Machine uses Emuge tools mainly for tapping, the company also uses the supplier’s thread mills for blind holes so it does not have to go back and hand tap the hole to depth, Mr. Fiers says. “We selected Emuge taps for their performance, quality, cost savings and support,” he says. Emuge also trained G&G employees on product use. Today, 95 percent of the company’s taps and thread mills are from Emuge, ranging in size from 4-40 to 1.5 inch.

As G&G strives to perpetuate its core ideology and lean practices using Emuge tooling, the company is able to more efficiently produce high-quality products. “When employees produce high-quality work, pride, satisfaction and profitability surely follow,” Mr. Stumpf says.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreBriquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)