Collaborating for Competitiveness

These seven aerospace shops prove that blurring the line between competitor and collaborator can benefit all involved—if it’s done right.

Share

The large plasma screen overlooking the shop floor at Vanderhorst Brothers is a potent symbol of the value of open communication in manufacturing operations. Showcasing up-to-date metrics and performance data, the display keeps everyone aware of where things stand and actively engaged in addressing areas that need improvement. More notably, it is a physical manifestation of the fact that information sharing goes beyond the company’s own four walls. Installing the screen was just one of many changes made as a direct result of consultations with a select group of local shops—shops that for all intents and purposes are competitors.

Vanderhorst Brothers has been participating in these consultations since the inception of the Southern California Manufacturing Group (SCMG) in 2004. The SCMG consists of seven Los Angeles-area aerospace manufacturers that share knowledge and resources to help one another improve. Shopfloor best practices, training, sales and marketing strategies—few topics are off-limits, and discussions are more than skin deep, with members sharing sensitive information about strengths and weaknesses alike.

In an industry where the slightest advantage can provide a significant competitive edge, such close collaboration might seem risky. However, for every improvement idea shared with the group, an individual member is likely to be repaid tenfold, says Dave Fisher, president of S&H Machine and founder of the SCMG. He and the other members agree that there is plenty of work to go around, and that working together to avoid making the same mistakes will help keep it that way. After all, without a stable community of competent, cost-competitive manufacturers in the United States, OEMs could turn elsewhere. “It is our hope that other companies will form their own peer groups so they can learn, improve and be successful in keeping manufacturing here at home,” he says.

He’s quick to add, however, that keeping a peer group viable and fresh takes a lot more than the occasional meeting. In the SCMG’s case, clear goals and expectations, highly structured activities, a rigorous application process for new members, and a culture of accountability all help ensure that membership in the group is truly a value-added proposition. More importantly, these characteristics play a key role in fostering the level of trust required for members to share the most intimate details of their operations.

Coming Together

Trust seemed a rare commodity among Mr. Fisher’s peers when he began looking for a group like the SCMG to join. Driven by a desire to continuously learn and improve, he had become frustrated by the lack of a window into the aerospace manufacturing world beyond his own shop and second-hand information from suppliers, customers and trade magazines. He had heard plenty about the potential benefits of a small, close-knit peer group from an uncle who worked in the printing industry, but a similar organization in the more secretive manufacturing sector simply didn’t exist. The only option was to create one. That effort began with a meeting of like-minded local business leaders who’d been recommended to Mr. Fisher by prominent equipment suppliers.

Nearly 10 years later, the SCMG is still going strong. What began with four shops has grown to include seven: S&H Machine, Vanderhorst Brothers, Roberts Tool Company, W Machine Works, Superior Thread Rolling Co., B&B Manufacturing and Warmelin Precision Products. Together, these companies represent more than 400 employees, nearly 400,000 square feet of manufacturing space, more than $40 million in annual procurement spending, and more than $100 million in annual sales. All activities are geared toward achieving four specific goals: to learn from one another, to develop the workforce, to streamline the supply chain, and to support manufacturing in the United States.

Making it Tick

Although the SCMG’s activities have expanded dramatically over the years in pursuit of those goals, the primary benefit for members remains the same. That is, the group provides a frame of reference for comparing performance and strategies with similar businesses facing similar problems and competitive pressures. These comparisons form a solid foundation from which the shops can improve by identifying best practices, zeroing in on inefficiencies that might otherwise go unaddressed and pooling resources to address common areas of concern.

As with any exercise in relationship building, getting comfortable enough with one another to make this collaboration work required time and the right combination of intangibles. Still, certain aspects of how the SCMG operates made it easier to develop the necessary rapport. These include:

• A Structured Approach. Avoiding wasted time is critical to keeping busy company leaders engaged. To that end, all interactions are tightly structured, beginning with the official monthly meeting. Hosted by member shops on a rotating basis, the roughly six-hour-long gathering is divided into various segments: general announcements from the president, treasurer and other officers; an open roundtable discussion; and some kind of learning initiative. The latter activity is often a tour of the host shop for a first-hand look at a problem or recent improvement. In other cases, outside experts speak on topics ranging from machining technology to complying with new health care regulations to employee interviewing tactics.

Hiring an outside facilitator to handle logistics and run meetings has proven critical to staying organized and on schedule, Mr. Fisher says. The facilitator also consults with officeholders to set the agenda for future meetings, and he helps organize various subgroups of middle managers, who meet periodically to discuss specific business areas like finance or human resources. The case is the same for other joint initiatives, including numerous outside training workshops and, most notably, the SCMG Supplier Conference. At this annual event, members host providers of heat-treating, anodizing and other services to work toward improving communication and breaking bottlenecks throughout the supply chain.

• A Clear Governing Philosophy. While structure keeps the SCMG focused, a lengthy list of specific bylaws codifies what’s expected of members. A few of these rules stand out as particularly important to facilitating the kind of interaction that makes the organization successful. First, everything discussed in a group setting is strictly confidential. Second, the monthly meeting is open only to two specific, top executives from each member company. This helps to avoid potential awkwardness and ensure an environment that’s conducive to sharing intimate operational details. Finally, and perhaps most importantly, the rules strictly forbid any form of direct employee recruiting from other members, price fixing or similarly unscrupulous business practices. “No one is in this group to get to know the others’ customers or pricing models,” says Doug Horton, president of Warmelin Precision Products. “It’s not about getting sales leads; it’s about improving our processes and improving our businesses.”

• A Rigorous Evaluation Process. Rules help, but they’re no substitute for true camaraderie. Thus, the decision to add a new member is never taken lightly. To even be considered, a company must have AS9100 certification, sustainable profit levels, a record of on-time deliveries and modern equipment. And whereas most decisions are made by majority vote, adding a new member requires the group’s unanimous consent. Moreover, the final decision comes only after a 6-month trial period so members can evaluate whether the proposed addition shares their values, including commitments to lean business models, continuous improvement and workforce development. Maintaining manufacturing diversity is also a concern because each company has its niche (for example, B&B Manufacturing specializes in hogging out large castings and forgings, whereas S&H Machine’s work often involves complex turning operations). The trial period also helps gage whether the new company’s leaders mesh well personality-wise. “The interpersonal connection is critical,” says Jeff Lage, vice president of B&B Manufacturing. “We have a great group of people who have all become very good friends, almost like family.”

• A Culture of Accountability. The lengthy waiting period also weeds out those who find the time commitment associated with SCMG membership overwhelming. Despite the genuine affection among members, this is not a social club. Those who don’t actively contribute will likely be asked to leave. Still, few formal mechanisms hold the shops accountable. Rather, the culture that naturally arises from a group of carefully chosen, like-minded individuals has proven more than sufficient. Given the window that a group like the SCMG provides into similar businesses, shop leaders who are truly dedicated to improvement can’t help but strive to outdo their peers.

BJ Schramm, president of Roberts Tool Company and the SCMG, says this friendly competition frees shops from the “tyranny of the urgent.” That’s his term for the tendency of immediate concerns, such as getting parts out the door, to preclude attention to efforts that are longer-term but no less essential. Without the SCMG, shops might procrastinate on such efforts, but the expectation to present results to the rest of the group compels them to get things done. Setting goals and working to achieve them in full view of peers also motivates shopfloor employees and encourages them to take pride in their work. Finally, collaborating with other shops helps avoid false starts and dead ends. “Having someone to compare notes with means you don’t have to reinvent the wheel—you can ask ‘How did you do this?’ or ‘Why didn’t this work?’” Mr. Schramm explains. “Individually, we wouldn’t have that kind of reference point.”

Looking Ahead

As evidence that truly engaging in a close-knit peer group is well worth it, Mr. Fisher cites the SCMG’s longevity—“People vote with their feet,” he notes. Still, the future holds daunting challenges. The group is pursuing training efforts in earnest to combat the skilled-worker shortage, to name just one example. Other discussions revolve around the increasing prevalence of difficult-to-machine, high-temperature alloys and continuing consolidation in the aerospace industry.

Amidst all this change, however, the basic model for the SCMG is expected to stay the same. These seven companies remain confident that they can help one another overcome new challenges, just as they collaborated in the group’s earliest days to implement lean practices, pallet-fed machining cells, flexible manufacturing systems and a host of other dramatic changes. With a similar philosophy and the right group of dedicated peers, perhaps other shops in other industries can do the same thing.

For more information about the Southern California Manufacturing Group (SCMG), visit thescmg.com.

Related Content

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreKennametal Turning Tools Enhance Small Part, Medical Machining

TopSwiss Micro Boring Solid tooling and KCU25B turning inserts are well suited for the small parts and medical machining space.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreRead Next

Cells To The Max

Brad Hart, president of Roberts Tool Company, in Chatsworth, California, believes that automated cells are the key to survival for companies likes his that machine complex, high-precision parts for aerospace and defense. Cellular manufacturing makes it possible to reduce lead times dramatically and minimize labor input while increasing throughput and improving quality, he says. In his shop, a cell consisting of two Toyoda HMCs and a dozen pallet stations epitomizes the lean manufacturing concepts that Mr. Hart finds so compelling. However, he says that shop owners have to get out of the business of making parts and into the business of building processes--processes such as those embodied in a lean manufacturing cell.

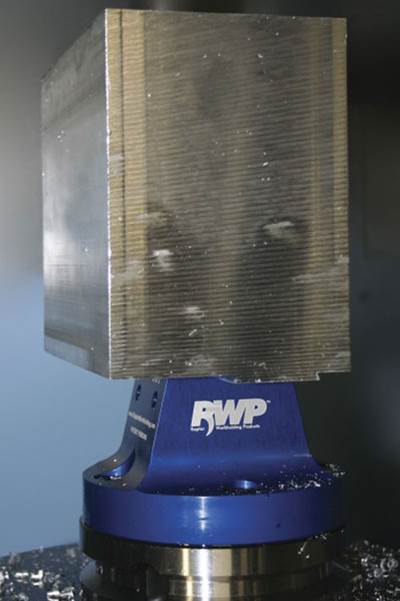

Read MoreJob Shop-Developed Dovetail Fixture Takes Wing

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Read MoreSharing The Big Picture

The theme of visibility in manufacturing finds expression in numerous ways at this shop. One of the most conspicuous is the use of plasma displays in strategic areas to summarize the company’s performance as reported by its shop control/data-collection system.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)