Cells To The Max

Brad Hart, president of Roberts Tool Company, in Chatsworth, California, believes that automated cells are the key to survival for companies likes his that machine complex, high-precision parts for aerospace and defense. Cellular manufacturing makes it possible to reduce lead times dramatically and minimize labor input while increasing throughput and improving quality, he says. In his shop, a cell consisting of two Toyoda HMCs and a dozen pallet stations epitomizes the lean manufacturing concepts that Mr. Hart finds so compelling. However, he says that shop owners have to get out of the business of making parts and into the business of building processes--processes such as those embodied in a lean manufacturing cell.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreBefore moving to flexible, “lean” manufacturing cells, Roberts Tool Company generated about $110,000 in revenue per employee per year. That was back in 2000. At the time, this Chatsworth, California, shop had around 50 employees and was not quite a $6 million a year company. In 2006, however, it did business worth $18 million—with 79 employees. That means that annual sales per employee had jumped to nearly $240,000.

Brad Hart, one of two brothers who own and run the company, attributes that change to the move to cellular manufacturing. “For us, it’s the only way to go,” he says.

Mr. Hart is convinced that automated cells are the key to survival. “Cells are the only way to make a healthy profit,” he says. Cellular manufacturing makes it possible to reduce lead times drastically and minimize labor input while increasing throughput and improving quality, he says. Currently, the shop has seven cells in place. The most elaborate cell consists of two Toyoda HMCs and a dozen buffer stations along a rail-guided pallet shuttle. This cell epitomizes the lean manufacturing concepts that Mr. Hart finds so compelling.

He also believes that cellular manufacturing is “the only way to go” for shops that are in the same business as his—making complex, high-precision parts for aerospace and defense. Although these shops may be his competitors, Mr. Hart is actively encouraging and helping them to adopt lean, cellular manufacturing. “It’s essential if we are going to keep this kind of manufacturing in the United States,” he says. Having a viable community of capable, competitive machine shops in this country prompts customers such as Boeing and Parker Aerospace to turn to Mr. Hart’s shop and other domestic manufacturers first.

In fact, Mr. Hart has become a sort of missionary for lean manufacturing with automated machining cells. Roberts Tool is a member of the Supplier Excellence Alliance (SEA), a membership organization consisting of prime contractors, tier-one suppliers and other supplier companies in the aerospace, defense and space industries. SEA was formed in 2004 to promote the adoption of lean manufacturing and other techniques that bolster supply-chain efficiency and competitiveness.

Mr. Hart frequently gives presentations to small- and medium-sized manufacturing companies in the aerospace/defense supply chain and participates in other efforts to promote SEA’s Lean Enterprise System. “I’m trying to show these companies how they can give their customers a 20-percent price reduction and still make twice as much money as they used to,” he says. It’s a simple but powerful message. Of course, Mr. Hart has to be prepared to use his own shop as an example of how this is done.

“I don’t care if these companies do become my competitors,” he insists. “If the U.S. supplier base as a whole can’t deliver this kind of value and do it profitably, the work will go to countries that can.” He believes that cellular manufacturing concepts can help other companies like his become globally competitive. “There’s plenty of work for all of us in the supply chain. Growth won’t come from us stealing jobs from each other,” he says.

Embracing Lean

Roberts Tool Company was started in 1957 as a machining job shop. Mr. Hart’s father bought the company in 1986 and moved it into the era of CNC machining. Complex hydraulic pump components became its specialty. However, the shop was organized in a typical job-shop fashion. Stand-alone machine tools were grouped by type. Batches of parts moved from machine to machine, often waiting to be processed while jobs ahead of them were finished.

Mr. Hart and his brother Bill took over management of the company when their father retired in 1998. This transition in management occurred at a time when many of the shortcomings of traditional job-shop organization were becoming widely recognized. New philosophies about production efficiency, teamwork and constant improvement were exposing these weaknesses and pointing to a solution. Robert Tool was a good candidate for positive change. Its lead times were long. Setting up a job often took longer than total machining time. Work in process (WIP) and parts inventory were tying up capital. The company was achieving only three or four inventory turns a year.

Fortunately, one of the company’s best customers introduced Mr. Hart to the concepts of lean manufacturing, which he embraced enthusiastically.

For Roberts Tool, the adoption of lean manufacturing meant a fundamental shift in both tactics and strategy. On a tactical level, lean manufacturing presented a methodology for systematically reducing or eliminating activities that did not add value for the customer. On a strategic level, lean manufacturing compelled the shop to move away from being a pure job shop. Ultimately, lean manufacturing led the shop to install machining cells. As Mr. Hart saw it, lean manufacturing would be most powerful in situations involving part families for similar customers.

“A job shop can make anything for anybody, but we saw a bigger opportunity to be a low-cost, short lead-time manufacturer of niche products,” Mr. Hart explains. The shop focuses on complex, high-precision parts for customers in the aerospace and defense industries because these customers are the most likely to continue manufacturing in the United States, especially with partners who can offer competitive prices and short lead times. That’s the kind of partner that Mr. Hart intends his company to be.

“We are not a job shop,” Mr. Hart insists. “Job shop” implies a business model that Roberts Tool no longer fits. The company does not sell machine time by bidding against other shops for whatever orders it can win, never knowing what job or part quantities will come through the shop. “We need parts to repeat,” Mr. Hart says. In this business model, the shop provides dedicated capacity at the disposal of the customer. “That takes the customer out of the forecasting business,” he says. Lead times are not a significant factor for either the customer or the shop. “All we need to know is how many parts should be produced and when they need to be delivered,” he says.

The appropriate machining cell can then be scheduled accordingly. Because setup time is measured in minutes or less and cycle times are proven, the shop simply has to ensure that the cell can hit the appropriate takt time—the pace of production dictated by the customer’s demand.

“There is no batching and no inventory of WIP,” Mr. Hart explains. “There are only two kinds of parts on our shop floor—blanks or finished parts ready for shipping. If the customer hasn’t ordered it, we don’t start machining it.”

What Is A Cell?

Mr. Hart does not define a cell by the presence of a robot, guided vehicle or other particular component. Any grouping of equipment arranged for one-piece continuous flow (blank part goes in, finished part comes out) with the capacity to achieve the appropriate takt time (the pace of production that matches customer demand) and meet all quality specifications is a cell. Provisions to minimize or eliminate setup time and other activities that do not add value make a cell “lean.”

Continuous flow and takt time dictate cell design. What processes have to be provided to complete the part within the equipment grouping? How much of each process is needed to turn out parts fast enough to deliver orders on time? The answers to these questions may call for an automated, multi-machine cell, or they may call for a single, manually loaded VMC with a cluster of auxiliary hand-operated workstations. Roberts Tool has examples of both types, as well as several in between.

“It’s all about having the right tool for the right application,” Mr. Hart explains.

The most elaborate and capable cell is the one built around a flexible manufacturing system from Toyoda Machinery USA (Arlington Heights, Illinois). It is a good example of cell designed to be “the right tool for the right application,” as Mr. Hart says.

The FMS consists of two FA400 HMCs arranged side by side along a track for a rail-guided vehicle (RGV). These 30-hp, 40-taper machines have the power and precision to produce complex hydraulic manifolds and other jet engine components from solid titanium at tolerances of ±0.0005 inch. Each machine has a 120-pocket automatic tool changer (ATC).

The RGV shuttles 400-mm pallets from a setup station at one end of the FMS to the machines’ pallet changers or to any of the nine buffer stations, which are lined up along the track opposite the machine tools. The FMS can accommodate 14 active pallets at one time. The pallet changers at each machine ensure that production is interrupted only long enough to exchange a pallet of finished workpieces with a pallet blanks. By filling the buffer stations with pallets loaded with blanks, the FMS can run continuously with little operator intervention for extended periods of time.

The FMS is controlled by the builder’s proprietary Mach III cell controller software. This system coordinates the movements of the RGV and keeps track of the order in which pallets are delivered to the machine. It also downloads the appropriate CNC programs and tooling data to each machine as the corresponding pallet arrives. According to Mr. Hart, the strength of the control system was a major selling point of the FMS. “It gives us the level of automation and flexibility we need to operate the FMS as a lean cell,” he says.

The FMS itself follows the builder’s standard, pre-engineered configuration, which is modular to allow installation with any number of machines. For example, the FMS at Roberts Tool could be enlarged by extending the track, installing a third machine and adding more buffer stations. What makes this FMS a lean machining cell are the accommodations for off-line preparation of the pallets and cutting tools.

Off-Line Setup For Zero Time

“This is how we achieve near-zero setup and changeover on this cell,” Mr. Hart points out. “Zero setup and high throughput make this cell a highly productive moneymaker,” he says.

All of the pallets are equipped with upright workholding pedestals. At least two fully fixtured pedestals have been built up for each part assigned to this cell (one for processing in the machine and one for waiting in queue). The pedestals are kept on dedicated pallets and, when not in use, are stored on shelves near the operator’s station toward the end of the FMS. (This point-of-use storage minimizes travel for the pallets and steps for the operator.) Even though the cell can produce several part numbers, it needs relatively few pallets. That’s because many of the pallets can accept multiple part numbers.

“When an order comes in for a certain part, we simply retrieve the pallet for it, load the solid blanks at the setup station and queue it up at the machine,” Mr. Hart explains.

Likewise, all of the cutting tools required to fully machine any part that enters the cell are kept in the machines’ ATCs at all times. Replacement tools to replenish the ATCs are prepared in this area of the cell, too. Tools are preset and kitted in carts, then switched in at the beginning or end of a work shift.

“This all happens off-line,” Mr. Hart says emphatically. “Setup and tool prep have zero impact on part flow.”

Equally important is the consistency of setup that this approach ensures. “Parts are always located and fixtured exactly the same way, and that is essential to quality part production, he says. No variables are introduced to affect output.

Before this cell was installed, the shop made parts like these on stand-alone machine tools. Typically, it took two weeks for setup and another week for first-part inspection and buy-off. The shop needed 6 weeks lead time to run an order. Today, it needs 3 days.

The bottom line is this: cellular manufacturing takes out most activities that do not add value to the part while speeding up the activities that do. “That means we can take the cost of this waste out of the price of the part yet still earn almost twice as much per spindle hour,” Mr. Hart says. The overall higher throughput of the shop is reflected in the fact that inventory turns per year have increased from four to 12.

Building Processes, Not Making Parts

Mr. Hart believes that designing a cell is both a science and an art. It’s a science in the sense that lean manufacturing concepts such as continuous flow, takt time and setup reduction take much of the guesswork out of sizing and specifying the equipment for a cell. It’s an art in the sense that spotting and exploiting opportunities for profitable operations require a “feel” for the kinds of parts and part groupings that lend themselves to cellular manufacturing. However, mastering cellular manufacturing concepts is not what holds back many shops.

Shop owners are more likely to have difficulty grasping the fact that they have to get out of the business of making parts and into the business of building processes, Mr. Hart contends. “Building a process requires a substantial upfront investment, but both the customer and the supplier get a lasting pay-off,” he says. Designing and building a cell and working out all the details of off-line setup, fixturing, tooling, programming and inspection routines necessarily take more time and money than traditional job-shop thinking can justify in its usual quoting practices.

That thinking misses the point. According to Mr. Hart, the point of building a process, as embodied in a lean manufacturing cell, is to lock down both a significant cost reduction for the customer and substantially improved profit margins for the supplier. As he puts it: “Once you’ve made the investment in building the process, its cost-saving, profit-boosting effect is brought to bear every time a customer order is filled by that process. And you can prove that to the customer by sharing the design concept. Why should customers for that process try to find a shop that promises a 1- or 2-percent reduction when you can offer a 10- or 20-percent price cut for as long as the part is in production? At the same time, the cell’s high throughput gives it exceptional earning power that is protected from being eaten away by excessive setup, high scrap rates and batching bottlenecks.”

Mr. Hart recently had the chance to demonstrate the value of process building to one of his best customers in the small aircraft industry. He was asked to create a model cell that could be compared to the customer’s traditional job-shop source. This model cell had to meet the following goals:

- Reduce cost by 10 percent at the outset.

- Reduce leadtime by 80 percent.

- Reduce setup time by 90 percent for all 30 different parts made in the cell.

- Maintain SixSigma quality in real-time process monitoring.

- Operate the cell with unskilled labor following standard work procedures.

- Make at least twice as much money as comparison suppliers.

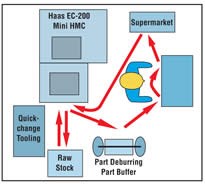

In eight weeks, Roberts Tool had the cell up and running. A schematic is shown on page 84. The cell occupies only 240 square feet of space. The operator travels only 10 feet in each part cycle. A system of visual signals (a “supermarket” in lean terminology) tells the operator what part to make next, so there is no formal scheduling. A KanBan system provides visual signals when cell supplies need to be replenished. Here’s what the project accomplished:

- All 30 parts can be set up in less than a minute off-line (thus, zero online setup time).

- Lead time to complete one set of 30 parts for shipping is 1 day for machining, 3 days for surface treatments and painting.

- Process control is maintained at 1.33 Cpk or better.

- Every aspect of cell operation is documented, and standard work procedures are fully established.

- Running the cell requires no special skills or previous training.

- The cell generates $286 in revenue per hour with one unskilled operator.

The competing source’s process had a leadtime of 87 days. This supplier needed 39.7 hours to a complete one set of parts for shipping, compared with 9.8 hours at the Roberts Tool model cell. The original supplier consumed 70 hours of setup time per “shipset,” compared with zero setup time for the model cell. Whereas the original supplier had 57 sets of parts in process at a time, the model cell had only three sets. Bottom line: the cost to the customer from the old supplier was $4,078 per set of parts. The cost from the model cell is $3,570. The original supplier made $76.29 an hour with his process. Roberts Tool made $286.65 an hour on the model cell.

These results reinforced the customer’s intent to promote the lean cellular manufacturing approach to all of its sources in the supply chain. The model cell at Roberts Tool is serving as an example to these suppliers of both what can be done and what needs to be done.

More True Believers

Mr. Hart hopes that other shops will follow the lead of Roberts Tool. “I don’t try to tell other shops how to run their businesses. I do try to show them how I run mine,” he says. He can see encouraging results. One recent development he cites involves a shop owner who meets with a group of local aerospace suppliers for peer review. Mr. Hart represents Roberts Tool at these meetings. After hearing about the Toyoda FMS cell in place at Roberts Tool, this shop owner recognized that a similar system from this builder was the right solution for his situation as well. The system is currently on order.

Finally, Mr. Hart notes that he wants his own employees to be true believers in the advantages of lean manufacturing and cellular machining. To this end, his company has implemented a system to share productivity gains with employees. The formula is based on the ratio of net payroll to net sales, and it creates an incentive to remove waste from shop operations. In short, the value of lean manufacturing comes across in fatter paychecks.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreRead Next

Lean Manufacturing Shapes A Cell

A machining cell that seeks to optimize product flow may look very different from a cell that seeks to optimize a machining process.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

%20and%20cell%20operator%20Alex%20Montiel.jpg;width=860)

.jpg;maxWidth=300;quality=90)