CNC Data Feeds Make Social Distancing Easier

Machine monitoring helps work remotely, avoid close contact on the shop floor and prevent underbilling for lights-out machining.

Share

Charlie Hill and other shopfloor employees at Optimize Technologies interface with the FactoryWiz monitoring system directly from their workstations. Image: FactoryWiz.

As the economy continues to open, I continue to count myself among the fortunate. Beyond being healthy and employed (so far), I’ve been grateful that much of my work lends itself to isolation. In fact, I’d often seek out isolation before it became easier to find, whether that meant shutting my office door, retreating to a park, or working from home to create the mental space I need to think and to write.

Adapting hasn’t been as easy for those I write about, but there are tools at their disposal. For instance, automation has helped machine shops practice what is effectively a form of social distancing for years. And, not unlike the digital tools I use to connect with the office, machine monitoring systems can make these shops even better equipped for an era when lights-out machining is about safety as well as economics.

I recently had a conversation about machine monitoring and social distancing with Richard Hefner, vice president at FactoryWiz, and Domenic Lanzillotta, who manages sales for that company’s machine monitoring and DNC software. Perhaps the most obvious advantage of the technology is the capability to monitor equipment remotely, from any web-enabled device. Additionally, automated text or email alerts tied to user-specific conditions — machine alarms, temperature thresholds or tool life thresholds — keep planners updated on what’s happening in the shop from the comfort of their homes (or anywhere). “Some companies make their server accessible through the internet with a secure login,” Mr. Lanzillotta says. “Other companies mandate a VPN or remote screen mirror connection to comply with ITAR or other government and industry requirements.”

Information from ERP is suspect. Data pulled directly from the CNC is not.

Other benefits are less obvious. For example, Mr. Hefner and Mr. Lanzillotta point out that machine monitoring can also help people keep their distance at work. Access to information helps individual employees answer questions without leaving their workstations. Dashboards at individual workstations facilitate communication, such as letting the quality department know a part is ready for inspection. They say large, public dashboard displays on TV monitors are ideal not only for this purpose, but also for boosting productivity by putting individuals’ work in context and instilling a sense of ownership in that work.

Machine monitoring also helps quoting, an advantage that is particularly useful for job shops and other high-mix operations facing staff reductions. Manually logging times into enterprise resource planning (ERP) software or other management systems is no way to track and bill for long stretches of unattended machining on many different parts, Mr. Hefner and Mr. Lanzillotta say. The same can be said for work involving lengthy cycle times, Mr. Hefner adds, citing the example of an EDM that stops in the middle of the night.

Shops that rely on overly generic, questionable cycle time estimates are likely to consistently underbill unattended work, he says. Most shops understand the problem, but not the ease with which machine monitoring software can address it. In short, information from ERP is suspect. Data pulled directly from the CNC is not. “Sometimes the job number is embedded in the program, or maybe we query the ERP when the machine runs a program to see which job requires it, then credit that job,” Mr. Hefner says. “In the end, they get the actual time of production rather than a guess.”

Finally, Mr. Lanzillotta notes that the ability to implement monitoring without having anyone physically on site to do the work was particularly beneficial in the early days of the lockdown. The case is the same for existing users who want custom dashboards or tablet interfaces. As posted on FactoryWiz’s website in early April, a time when manufacturers not deemed essential were shutting their doors around the country, its technicians “can’t fly to customer sites for new installations — but they’re set up at home and doing a great job installing as much as they can remotely for newer equipment. With a remote meeting to your server, they will get FactoryWiz going right now, when you need these tools the most.”

Related Content

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreRead Next

Can Sharing CNC Data Lift the Machining Industry?

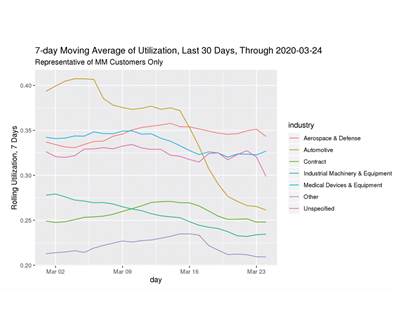

Masses of anonymous metrics arrive ahead of even the leading economic indicators and help machine shops benchmark performance.

Read MoreCoping with the Coronavirus — One Shop Manager’s Thinking

This president of a machining job shop is preparing for the situation to last and focusing on communication and a positive environment for employees.

Read MoreMachine Monitoring Enhances Human Resource Functions

Decisions about manufacturing processes are not the only business factors that can be improved by the insights derived from data collected by a machine-monitoring system. For this shop, using this information to strengthen and fine-tune its employee incentive program is a significant benefit, among many others.

Read More