Can A Machining Center Be Used As A CMM?

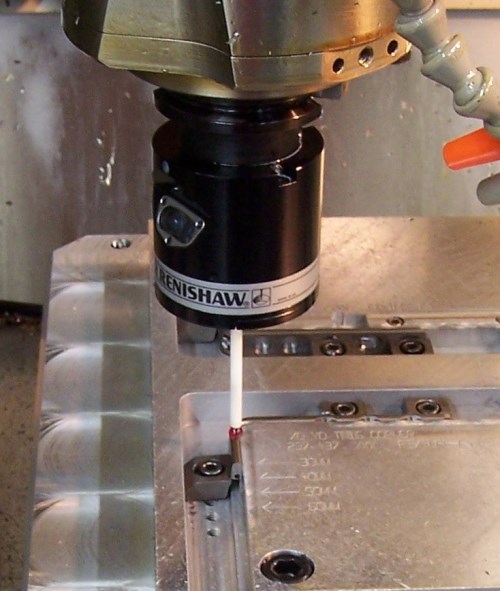

One manufacturer in need of a shop-rugged CMM wants to use a probe-equipped VMC for precisely this purpose. The shop asked probing expert Renishaw about this idea. Here is the response.

Share

A reader from a precision-machining contract manufacturer recently used the “Ask An Expert” feature of our Inspection & Measuring Equipment Zone to ask the following question:

Question

We are considering using a new VMC as a CMM on the shop floor. The machine has covered ways and it’s designed to work in that environment. What are the benefits/drawbacks to this approach?

Response from Dave Bozich, machine tool business manager with Renishaw

Using a machining center as a shop-hardened CMM is not impossible. It is done very infrequently because of the detailed knowledge of metrology necessary to get satisfactory results.

There are three primary uses of a machine tool probe. In order of popularity:

1. Pre-process. Before a machining process commences, a probe can be used for job setup. Typically the probe is used to determine part location and automatically update a work coordinate system. This is by far the most popular use of machine tool probing.

2. In process. During the machining process, a probe can be used to verify that the part is being machined to tolerance. This allows the machine to check itself, keeping the loop closed and reducing the need for operator intervention.

3. Post-process. After the part has been machined, the probe can be used to verify that the part was machined correctly. The challenge with post-process inspection is that errors inherent in the machining cycle may affect the measurement results. In order to ensure the integrity of the measurement process there are a couple of recommended metrology principles to follow:

A. Calibrate the machine using a laser interferometer, telescoping ballbar and other metrology equipment (electronic levels, alignment lasers, spindle analyzers). This ensures the machine meets the highest performance standards.

B. Certify the machine’s ability to perform as a measurement system. This should incorporate repeatability and accuracy tests. Repeatability tests ensure the machine "hits the target" repetitively. Accuracy tests ensure the machine can replicate a measurement verified by another source (i.e., a CMM).

The bottom line: If you keep the machine healthy through calibration and alignment, and certify that it has the ability to perform as a measurement system, then you could get CMM-like results from your machine tool. Other important factors to consider include the type of probe, measurement strategies and software.

Related Content

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.