CAM Software Provides Competitive Edge in Bringing Ideas to Life

Intriguing Concepts LLC, a mold prototyping and production shop, uses Surfcam CAM software to achieve better surface finishes and production times.

Share

Oftentimes, turning an idea into reality is easier said than done, yet brothers Thomas and Alan Valentine, co-owners of Intriguing Concepts LLC, say they are up for the challenge. As a one-stop shop for both mold prototyping and production, the company uses Surfcam CAM software in order to stay competitive using complex machine tools. The CAM software helped the company to slash production times and increase its overall business by 31 percent from last year.

Based in Harrison Township, Michigan, Intriguing Concepts has been materializing the concepts of its customers since 2004. Though the majority of the workload involves manufacturing plastic injection molds for the medical and electrical industries, the business also produces automotive, hunting and dairy products. One such dairy product is a pumping diaphragm with some assemblies that require seven or eight working components. Along with working on challenging products such as these, Alan says he enjoys finding ways to complete manufacturing projects that others deem impossible.

The brothers’ can-do attitude is an ideal match for the prototype development and manufacturing that accounts for nearly 75 percent of the business. Production accounts for the other 25 percent and is accomplished with the company’s 10 molding machines that range in size from 15 to 90 tons.

In the early 1990s, before the birth of Intriguing Concepts, Thomas realized it was tough to operate advanced CNC machines without a CAM solution. His self-proclaimed “old school” method of manual programming was virtually impossible on the new machines, he says.

The market was evolving and the company needed to embrace new technologies to stay afloat. For instance, what took 10 hours on a Bridgeport took only 90 minutes on a CNC machine tool.

“If you can take eight hours of manual labor out of a job, you can obviously be a lot more competitive,” Thomas Valentine says.

Today, the brothers utilize a Mazak VTC 16B vertical machining center, a Haas VM-2 vertical mill, a handful of Bridgeport mills, a Jet lathe and several surface grinders that are used for finishing work. The company machines in as many as four axes, and while many of the parts it makes aren’t especially complex, tight tolerances must be maintained, which adds to the overall challenge of production.

To competitively cut small, precision parts, Mr. Valentine chose Surfcam by Vero Software (Thousand Oaks, California), largely because of its power and ease of use. He says he can train an employee in Surfcam and make him somewhat fluent on it in less than a week. Also, the software communicates seamlessly with Solidworks’ CAD solution, enabling him to import any file from Solidworks with no issues.

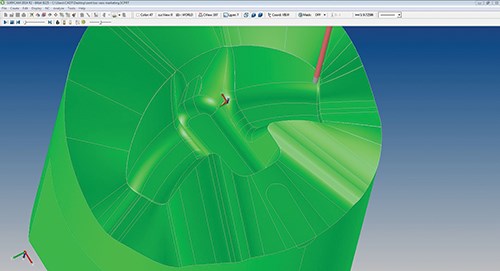

Three main Surfcam features have been key for Intriguing Concepts: “Z-rough,” rest machining and 3D offset finishing.

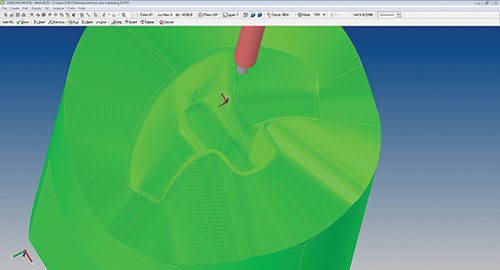

The time-saving Z-rough cycle is a roughing cycle along the Z axis that rapidly removes large amounts of stock to prepare for other operations. Using a two-axis (X, Y) pocketing cycle in Z-axis increments, this operation is an efficient method for removing large amounts of material from around a part before additional operations perform the finish cutting.

As a preliminary step in Z-level roughing, programmers must identify the size and shape of the material from which the part will be rough cut, and Surfcam offers a number of options that enable the programmer to easily do so. Z roughing is also used to remove large amounts of material from inside a cavity.

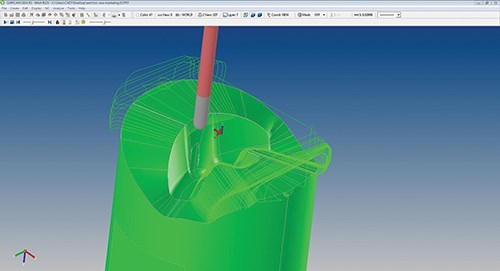

Surfcam’s second key feature, rest machining, enables the system to recognize the last tool

used. The programmer then picks a smaller cutter and it then calculates the remaining material to be removed. For example, when a pocketing or contouring operation is performed, material typically remains on the sides of the part because it was located in areas too small to be accessible by the tool. The rest machining is a secondary operation that removes the “rest of the material” from the sides of contours and pockets. If material is left at the bottom of a pocket, such as when a ballnose tool is used, other methods must be used to remove it.

“It calculates what has been removed and what still needs to be removed, and just goes to the corners and cuts,” Mr. Valentine explains. “If it didn’t calculate the areas that need to be removed, I would have to create boundaries, which takes more time.”

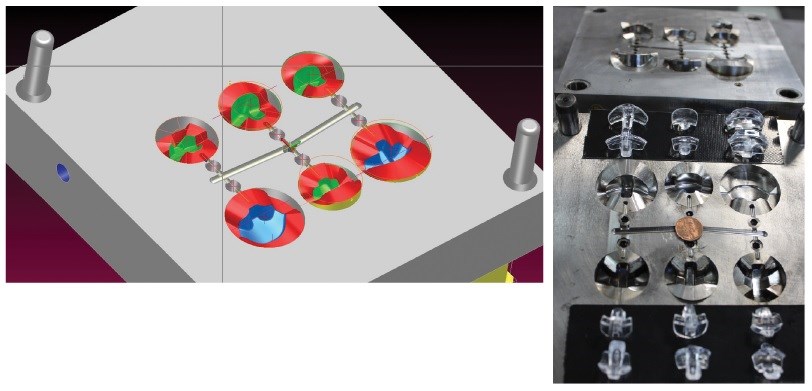

Finally, Surfcam’s 3D offset capability has proven to be beneficial in helping Intriguing Concepts save time. A recent project included a six-cavity dental mold that produced six different parts ranging in size from ¾ to ½ inch. The 3D offset capability ensured that the part remained in constant contact with the end mill, which led to substantial time savings on the shop floor.

“That’s the most powerful tool in the package,” he says of the 3D offset function. “It’s so powerful that I can’t think of any job that I don’t use it on.”

Along with saving time, the 3D offset capability helps deliver a superior surface finish by creating a single tool path across the entire part, which eliminates time-consuming lead-in and lead-out moves. The 3D offset finishing operation creates concentric offset cutting passes based on the shape of the outer contour of the part. The tool path maintains a constant scallop height, which results in a consistent finish.

There cannot be any parting lines or burrs in the final product, Mr. Valentine says of the dental application. “It has to be a perfect part; it’s going into people’s mouths.”

By creating a tool path based on the model’s surface, the 3D offset finishing operation performs movements parallel to the model to ensure uniformity. Its ability to echo the shape of the part results in a high-quality surface finish across the entire model, which reduces or eliminates the necessity for secondary operations to finish the part. Moreover, the constant cutter chip load produced by 3D offsets reduces cycle time by enabling significantly higher cutter speeds and feeds.

“I can create almost a whole job by using just a Z-rough, Z-finish and 3D offset,” Mr. Valentine says.

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)