CAM Software Improves Productivity, Lead Times

Implementing Mastercam CAM software has enabled this manufacturer to improve productivity and lead time despite limited staffing resources.

Share

With an experienced machine programmer capable of writing code for its three CNC lathes and a slew of skilled operators, the Motion Transfer Devices (MTD) Group of Alinabal had no immediate interest in acquiring a CAM system. Fate, however, had a different idea. In 2001, staffing changes forced the CNC lathe department to re-evaluate its workflow. To improve efficiency, the company invested in its first CAM system, Mastercam from CNC Software (Tolland, Connecticut). The software implementation has enabled the company to keep all its projects moving despite additional attrition during the past several years.

"If I had to name the three greatest advantages CAM programming has brought to our lathe operation, I would cite improved first-time success, reduced time required to make that first piece and the ability to mistake-proof the process," says programmer/operator George Yuhas. "These can be further boiled down to two enterprise-wide improvements: greater productivity and reduced lead times."

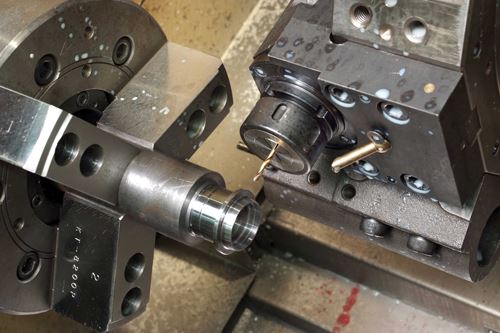

Based in Milford, Connecticut, Alinabal’s MTD Group produces an array of standard and custom rod ends, spherical bearings, linkage assemblies and self-aligning molded bearing assemblies. Primary markets include recreational vehicles, construction equipment, medical equipment and agricultural equipment. Although the shop is equipped with high-volume equipment for large lot sizes, most work in the CNC department consists of low-volume prototype jobs for new applications. "The shifter links, suspension links, brake links, steering linkages, rod end bearings and spherical bearings transfer motion in our company’s products," says Scott Haeffner, manager. "Often, these are safety-critical components requiring strict compliance to specification."

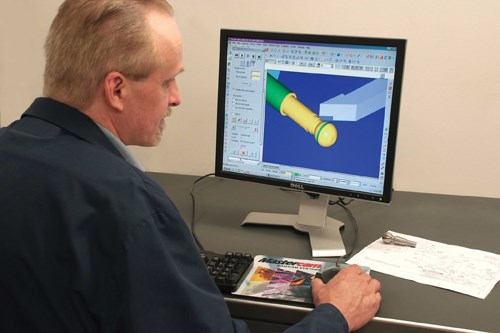

Mr. Yuhas recalls that he used to spend hours on complicated parts doing trigonometric calculations to create accurate points for manual tool paths. Now, toolpath generation is much faster with the introduction of CAM software, which has also contributed to a smoother, more trouble-free operation. However, this was just the beginning of many improvements—both intended and unforeseen—derived from the software implementation.

One of the most immediate benefits was an increase in machine capacity, Mr. Haeffner says. This is a result of the ability to perform programming and troubleshooting on a computer rather than at the machine. Verifying geometry during the programming process enables the shop to identify mistakes that would make manufacturing difficult or impossible much earlier in the process. One example is the detection of "open entities," a condition in which features defined on the drawing cannot be connected during the Mastercam chaining process. When a problem occurs, programmers can send the geometry back to engineering for quick revision rather than spending countless hours trying to correct it.

Seamless support for the shop’s AutoCAD design software is especially helpful here, as it allows flawless import of design models, the company says. "By integrating AutoCAD with Mastercam, we can immediately catch mistakes that we previously did not catch until we were on the machine," Mr. Yuhas notes. "It took a significant amount of time to generate the code, set up the machine and attempt to cut the first piece only to conclude that the part geometry was wrong. By checking the geometry within Mastercam, we know literally within an hour what used to take days to find out."

Quotes are more accurate, too, since implementing Mastercam. The software’s Backplot computer simulation capability allows Alinabal to estimate cycle times and factor them into quotes, even before producing the first part.

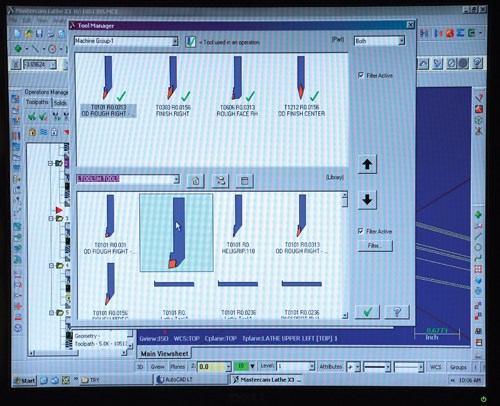

Overall manufacturing consistency has also improved significantly, thanks in part to custom postprocessors for the shop’s Fanuc-controlled Mori Seiki lathes. The posts were created through close collaboration with MacDac Engineering, a Mastercam reseller. Mr. Yuhas worked with MacDac to simulate the manufacturing of a variety of parts and modify the posts to ensure the machines behave the same way in similar situations.

These custom posts eliminate 99 percent of the editing that is often required to support specific machine functions, Mr. Haeffner says. The alternative—using generic posts and editing programs as-needed to support specific machines—was unacceptable because it provided opportunity for error and required additional programming time, he adds.

The ability to set up libraries of tools and their associated settings within Mastercam further contributes to improved consistency and faster programming. By retrieving these settings, programmers can ensure that manufacturing is consistent with proven methods from part to part. Users can create and store custom tool configurations as well.

Moreover, the shop’s custom posts aren’t the only feature of the software that benefits operations on its Mori lathes. The primary role of these machines is producing first-part prototypes, and such jobs often evolve during initial production. By allowing programmers to make feature-specific adjustments, the software reduces programming time for print revisions.

Another notable improvement since implementing the software is better first-time success rates. In fact, the success rate for manufacturing first pieces from CAM-generated lathe programs approaches 100 percent, Mr. Haeffner says. Mr. Yuhas remarks that while he used to put a stop after every line in a given program to check how the code was running, he now has much more confidence. "I select the tool, bring it up to the part and push the button. If there are 50 or 60 lines of information, I’ll just let it run through everything, and then I will check everything out. It’s so much faster."

Since implementing Mastercam, the shop has been able to complete complicated new programs that once took as long as 2 days in only 4 to 6 hours. For Alinabal’s customers, this means improved quality and shorter lead times.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)