CAD/CAM Software Contributes to Shop's Fourfold Revenue Increase

C&S Machine & Manufacturing has long applied CNC machining successfully, but growth started to expose the limitations of its programming processes. Esprit CAM software from DP Technology has helped to overcome these limitations and usher in even more growth.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreKeep growing, and eventually there will be growing pains. This was the experience of C&S Machine & Manufacturing Corp., a machine shop based in Louisville, Kentucky. The need to make the programming process more efficient became crucial to winning bids, which led the shop to acquire Esprit software from DP Technology (Camarillo, California).

Far from its origin in a 180-square-foot shed in 1969, C&S Machine & Manufacturing Corp. has three buildings today with more than 60,000 square feet housing 30 CNC machines including vertical and horizontal machining centers as well as vertical and horizontal lathes with live tooling. The company also offers lasercutting, bending and welding services.

As the company invested in its latest CNC machine tools, it began to experience limitations with its former CAM programming software. “The CAM software could handle nearly all of our programs, but it was somewhat awkward to use,” says machinist apprentice Kyle Dunn. “We would write a tool path, post it out and paste the resulting G code into our handwritten program. This process was time-consuming and prone to mistakes that might wreck a tool or workpiece.”

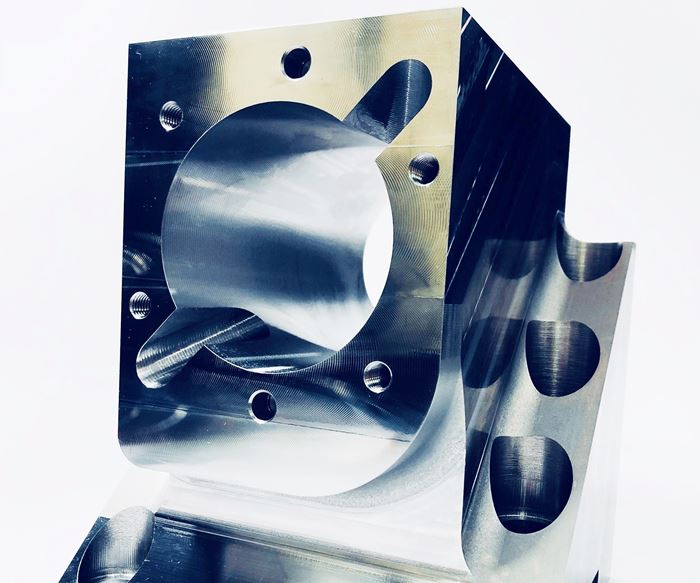

Machining a Lower-Jaw Part

A typical example of type of programming done with Esprit is a lower jaw for a custom-built stamping press. This part is produced from a solid piece of 10-by-9-by-8-inch alloy steel would have been challenging before using Esprit, says Ryan Steele, owner and general manager. “We would have been manually programming a lot of the drilling, hole locations, tap cycles and face milling,” he says.

After working out some of the more complex geometries on paper, they would have plugged that information into the old CAM software, which would be used as a basic G-code generator. Then, they would have copied and pasted the G code into the main program or run as a completely separate program. “Our ability to machine the various blended radii and complex geometries would have been heavily reliant on tooling, given the limitations of our software,” Mr. Steele says.

This process made it extremely difficult to compete on pricing. It also increased the chances of scrapped parts due to keystroke errors and made for longer lead times. Finally, retention of programs was a nightmare, Mr. Steele says. The company essentially started from scratch each time they made the part.

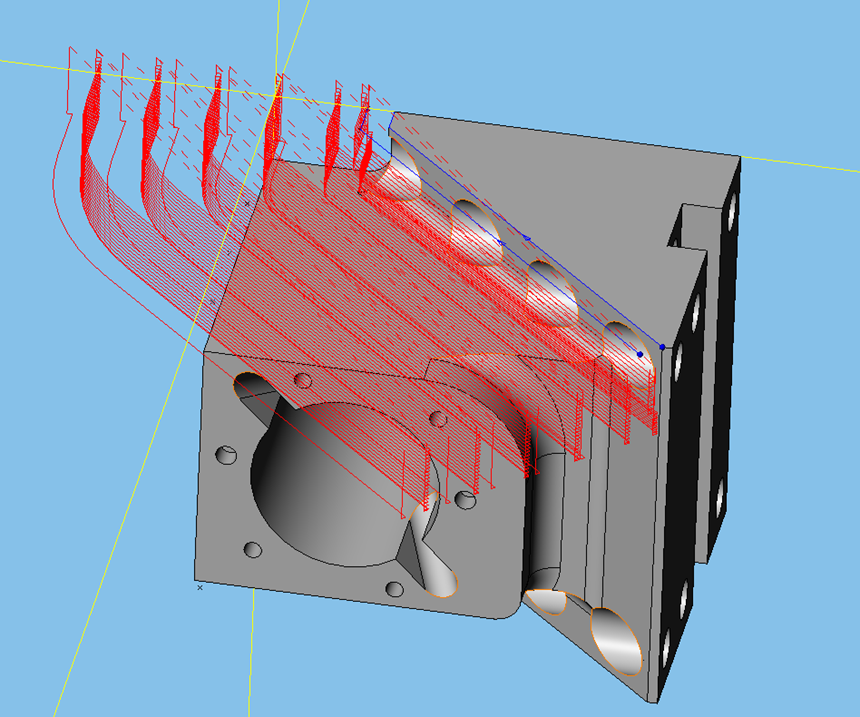

Instead, things were much better using Esprit CAD/CAM software. For the lower-jaw part, the customer provided a SolidWorks solid model of the part geometry, and the programmer imported the model into Esprit. (This import ability was a big draw for C&S.) The programmer then created a block around the part to define the workpiece from which the part is machined. He began the programming process by choosing from a tooling library that he had created in the past that includes ballnose end mills, square end mills, drills, taps and more. The library ensures that programming and simulation match the dimensions of the actual tooling including stick-outs, tool numbers, number of flutes and other considerations to ensure accurate collision detection.

He then used Esprit’s automatic feature recognition capability to restore the intelligence of the part geometry by organizing it into features such as holes, bosses and pockets. He selected many of these features for use in creating tool paths. The programmer created tool paths for the basic outline of the part by chaining edges and line segments to create a few larger surfaces covering the exterior of the part. He then selected these surfaces one at a time and defined contouring operations to produce them. He selected a contour-milling strategy for each contouring operation, and Esprit automatically generated an efficient sequence of roughing, semi-finishing and finishing operations to produce the surface.These operations begin with efficient roughing at high metal removal rates with an indexable end mill that can remove material all areas of the part can without gouging the workpiece. The program then loads the next smaller size tool and calculates which areas of the part it can remove. This process continues down to the smallest tool, usually a ballnose end mill, which generates fine details on the part.

When all tool paths were created, the programmer simulated the program operation in Esprit. The simulation generates a part model that can be easily compared to the design intent as provided by the customer. The simulation also estimates the cycle times, which helps to improve the accuracy of the company’s quoting. “We use this feature on long-term, higher-volume projects to estimate how much machine time will be required to produce each part,” says manufacturing engineer Mike Curry. Mr. Steele adds that the shop worked closely with Esprit to build and tweak its postprocessors to ensure smooth communication flow between Esprit and the machines. It helps C&S detect crashes in the software, reducing the time and expense of scrapped parts.

CAM Programming Improvements as a Source of Growth

“When the initial implementation began, we started from scratch,” Mr. Steele says. New PCs, electronic filing, printers and naming conventions all required a lot of training, but it was worth it. Additionally, the shop worked closely with Esprit to fine-tune its postprocessors: “We have worked on making sure all of our postprocessors post code in the same standardized format of our preference. When machinists and operators see a program in a machine, we want the format to look the same across the board.”

The increase in CAM programming capability provides several key benefits both to C&S Machine and its customers. The more efficient CAM programming workflow helps reduce programming time, for one. The automated strategies provided in Esprit reduce cycle time, which in turn helps reduce the cost of machining. Esprit’s realistic simulation and accurate postprocessors have eliminated problems such as crashes when running programs for the first time.

Operations manager Tom Grace has concluded that the use of Esprit has contributed to the more-than-fourfold increase in revenue since the company started using the software. “There are many factors involved in our growth, including investments we have made in new technology and workforce development, and the dedication and support of our entire team,” Mr. Grace says. “But there’s no question that the improvement in our CAM programming capabilities that we have achieved with Esprit have played a major role in our success.”

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)