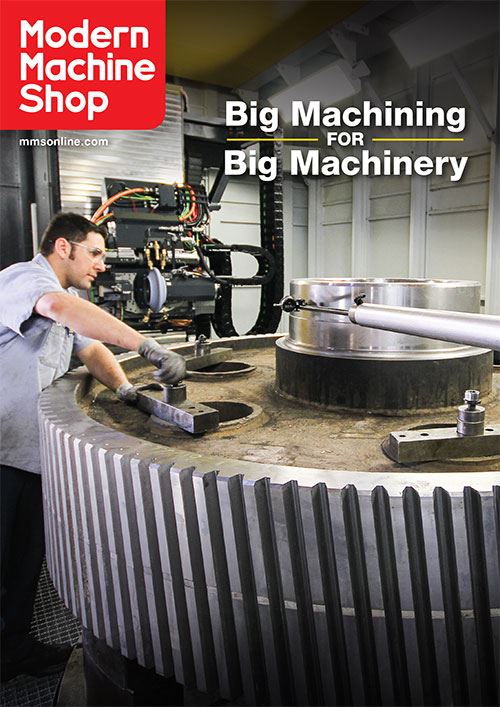

Big Machining for Big Machinery

A significant investment in machining equipment, including an advanced five-axis, 6-meter profile grinding machine, is enabling this Southwestern shop to be more competitive at producing large-scale gears, shafts and other mining components.

Share

The very large gears, shafts and related mining components that are machined at L&H Industrial’s Tempe, Arizona facility are impressive to see. What’s just as impressive, however, is the investment that the Wyoming-based company has made there since purchasing the operation in 2008. In the past few years, the company has invested more than $20 million in the facility by adding machine tools, refurbishing existing equipment and expanding the building. And this is just the beginning, Wayne Myers notes.

Mr. Myers has been employed at this facility for nearly three decades under three different owners. He’s worn many hats there over the years, working as a machine operator, sales representative and operations manager. He explains that until L&H purchased the operation, the shop (like many others that perform this type of work) relied on dated, manual equipment and traditional processes to produce large gears and components for mining machinery. Recently, however, the company has taken significant strides to make this operation more globally competitive, including the addition of an advanced 6-meter, five-axis profile grinding machine (one of only three such models currently installed in the United States and seven worldwide) to produce higher-quality gears with vastly improved surface finishes. It has also installed a huge, multifunction CNC lathe that will enable the shop to produce—in one setup—the types of long shafts that often accompany large gears.

A visit in early March with Mr. Myers (now a territory account manager) as well as Bart Wood, general manager, and Scott Bradley, area manager, enabled me to take the following snapshot of a transformational point in the shop’s evolution. While there, I was also able to learn about the additional investments that are on the horizon as the company strives to be a premier manufacturer of rebuilt and redesigned components for mining applications.

Gear Production via Conventional Means

In 1964, Leon Wandler founded L&H Industrial in Gillette, Wyoming with six employees. Today, the company has offices on four continents and more than 450 employees. L&H is a leader in the design and manufacture of aftermarket parts for mining shovels, draglines and drills. The company also specializes in providing field, repair and remanufacturing services for the global mining industry.

L&H is now owned by Mr. Wandler’s sons, Mike and Jeff, who purchased the Tempe facility so the company could expand its reach into Mexico and the Southwestern United States. The business at this location is split fairly evenly between rebuild work and new product design and manufacturing, the latter of which is exemplified by the company’s expanding Omega line of higher-quality replacement components and systems for OEM mining equipment.

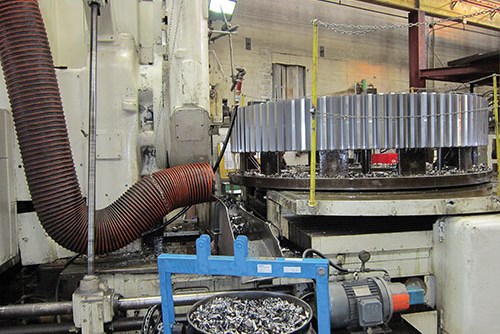

The Tempe facility was established in the 1970s to manufacture large gears. Until recently, it has primarily used World War II-era manual equipment and applied conventional large-scale gear-making processes. For instance, new gear blanks start at a gashing machine that roughs gear teeth profiles by removing much of the material between the teeth. Workpieces are then delivered to either a hobber or a gear shaper to complete the tooth profiles.

Hobbing machines feed rotating cutters ground with a specific involute profile into workpieces to create the teeth (hobbing cutters for large gears can cost as much as $20,000 apiece). Conversely, a gear shaper moves a relatively inexpensive planing-type tool (one that many shops can make themselves) up and down in one axis to create the tooth profile. During the tool’s non-cutting up-stroke, the machine’s saddle and rotary table move simultaneously a bit to mimic the motion of a gear tooth rolling in and out of mesh with its mating component. A tooth profile is completed with multiple downward passes of the tool along that path. Depending on the job, adjustments to the machine can be made to change the number of teeth and the tooth profile or pitch. This concept dates back to the early 20th century, but it has remained one of the most popular methods for machining teeth for large gears. Until recently, in fact, L&H’s Tempe operation used a 1950s-era gear shaper for final machining of gear teeth.

Improving the Process

Although designs for gears haven’t drastically changed over the years, the quality specifications that mining equipment OEMs demand have become more stringent. U.S. gear production is governed by the American Gear Manufacturer’s Association (AGMA), which establishes grades or classifications for geometric gear tolerances. A high AGMA number indicates a tight-toleranced gear in terms of tooth spacing, profile and lead.

Prior to L&H’s purchase, the highest rating the Tempe operation could achieve was an AGMA 8 on its gear shaper. However, many of today’s mining equipment OEMs now require gears with AGMA 10 quality. Realizing this, the company tasked Mr. Myers a couple of years ago with identifying the types of gear-making technology and processes that might enable the shop to attain an AGMA 10 quality level for large gears. Mr. Myers spent a year traveling the world networking with the gear-making community, and considered equipment such as a seven-axis milling machine and even a used gear shaper that was a prime candidate for a CNC retrofit.

However, he and others at the company understood that producing a gear with a quality tooth surface finish was just as important as achieving a high AGMA rating. Obviously, a finer surface finish means there’s less friction between mating teeth, minimizing the chance of pitting that can lead to premature gear failure. Mr. Myers notes that any hobbed or shaped tooth will have feed lines, and surface finish quality will not be better than approximately 100 Ra (as in the case with the shop’s existing gear shaper, even though it uses new-technology cutting oils and tools with advanced coatings).

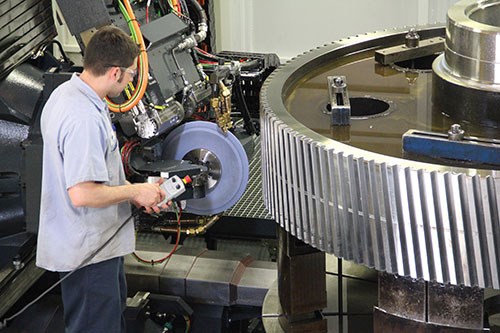

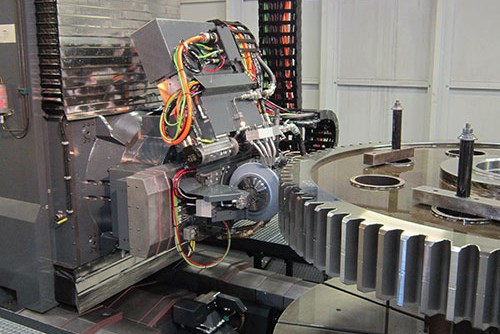

This prompted the decision last year to purchase a new five-axis Rapid 6000 profile grinding machine from Höfler, which can accommodate gears measuring 236 inches in diameter. Since being installed last year, this machine has enabled the shop to surpass its initial AGMA goal and finish-grind shaped gear teeth to AGMA 14 quality and 24-Ra surface finish.

Adding Grinding

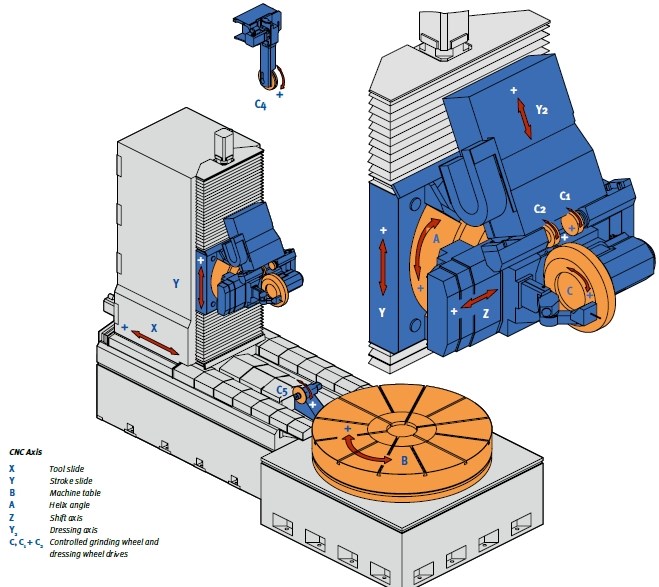

The Rapid 6000 is a five-axis profile grinding machine that accommodates workpieces with diameters ranging from 9.5 to 236 inches and a maximum face width of 80 inches. Mr. Myers says it has a number of features that enable it to effectively grind quality gear teeth profiles. For instance, the machine uses a mineral cast bed, which is said to provide improved damping and thermal growth qualities compared to cast iron. Therefore, processing and ambient facility heat have a significantly lower effect on the machine component expansion during operation.

The machine’s 2,350-mm-diameter table has a 50-ton load capacity and moves axially and radially on hydrostatic bearings. The table has a center bore with a diameter of 750 mm and a depth of 1,300 mm to enable shafts to be fixtured for teeth-grinding operations. In fact, the first part ground on the machine was large ball-mill pinion for iron-ore mining, which conventionally would have been gashed and hobbed. These operations could take as long as 50 hours to complete, but that first pinion took just 18 hours to gash and then grind.

Another advantage that Mr. Myers points to is that the machine uses table drives with torque motors for smooth, backlash-free motion. Its table indexes to within a millionth of a degree and can rotate as high as 70 rpm. In addition, the machine’s grinding head also features a torque motor with a direct-measuring system for accurate position control. A dressing system with two dressing wheels is integrated directly into the head, too. Dressing routines are called up automatically when the machine senses an increase in grinding pressure due to wheel build-up. After dressing, the machine’s control calculates the wheel diameter to automatically determine a new radial in-feed value.

During grinding, the machine can adjust its head’s helix angle and shift the grinding spindle tangentially for simultaneous five-axis motion. There is no limitation for the pressure angle, and helix angles can range from -45 to +120 degrees. The machine also has an internal grinding head installed on its tailstock that can be used to grind internal spurs or helical profiles.

But beyond these machine design features, Mr. Myers appreciated the positive feedback about service he received from other Höfler equipment users. As he networked through the gear community, users of multiple grinding equipment brands said Höfler service personnel notified of an issue would be on site within days versus sometimes weeks with other builders.

The Rapid 6000 has been in operation for just a year, so the shop is still on a bit of a learning curve with it. Rory Tagle, who has been an employee at this location for 12 years, is the machine’s first-shift programmer and operator. He has vast experience running manual machines whereby essentially every machine motion requires some bit of human definition, and admits that this mindset caused the move to CNC to be initially intimidating. However, the machine’s control with intuitive interface made programming relatively easy to pick up, he says, and he’s not tasked with programming or calculating every single machine movement or action (such as compensating for wheel wear, which the control does automatically).

Instead, he uses Höfler’s GearPro conversational-type programming system to simply enter a handful of parameters for a specific job. The standard software enables dressing of almost all involute profiles, and profile modifications are displayed graphically on the CNC’s monitor. In-process probing routines determine how much material remains left to grind after a pass. Plus, the machine’s touch probe is also used during final inspection after which an inspection report is automatically generated.

Grinding Sans Gashing

To date, the Rapid 6000 machine enables the shop to produce AGMA-14 gears with an excellent surface finish to ensure longer component life and quieter operation. However, a gashing operation followed by either hobbing or gear shaping is still required to create the rough teeth profiles prior to grinding. Therefore, the shop is investigating a process to enable the machine to completely grind gear teeth from a blank in one setup without pre-machining work.

Because the wheels that were supplied with the machine were designed for finish grinding of carburized or induction-hardened material, Mr. Bradley has been working with Norton Abrasives to develop wheels capable of producing gear teeth complete, rough-grinding the profiles in the soft state and finishing the teeth in the hardened state. In fact, the shop planned to begin testing this process the week after my visit.

As part of this new approach, a new coolant nozzle system from Cool-Grind was added to the machine. These nozzles use coherent-jet technology that features an internal nozzle geometry to create a tight, coherent jet when the coolant exits. This is especially important for grinding, because most of the heat goes into the part, not away with the chips. The stream’s high impact energy removes the boundary layer of air that oftentimes stops low-pressure coolant from wetting the wheel surface at high speeds. The concentrated stream enables the wheel to carry the coolant directly into the grinding zone. During installation on the machine, a miniature laser fitted to the tip of the nozzles enabled precise aiming of the jets.

Although this process will require much greater material removal and will take much longer than conventional skim grinding, the shop believes it will benefit by consolidating the operation on one machine to minimize setups and transport of the large workpieces.

Adding Capacity, Capabilities, Floor Space

Not all equipment the shop has recently purchased has been new. In fact, it’s had good results purchasing used machines. The huge, multifunction Ravensburg CNC lathe the shop recently installed is a good example. Although it had a VTL that could turn 29-foot-diameter parts, its horizontal turning capacity was limited to 40 inches in length. The Ravensburg, one of the largest CNC lathes in the Southwest, enables the shop to turn parts as long as 354 inches. And in addition to offering a 55-inch swing capacity, the lathe has a milling spindle and 12-station ATC providing the possibility to produce splined shafts, ball-mill pinions and similar components in one setup instead of moving workpieces across a lathe and a mill.

The shop has also had some of its existing equipment remanufactured and/or modified. For example, its British Craven gear hobber has been retrofitted with a CNC and modified to perform gashing work. In addition, the shop created a custom attachment to enable it to machine internal splines, starting with a straight end mill and finishing with a full-form end mill. Similarly, its Carlton five-axis CNC horizontal boring mill will soon be modified to provide more floor and head travel to machine larger gears in fewer setups. During my visit, the shop’s Betts horizontal boring mill was being retrofitted with a new FANUC control and drives. In addition, a 120-inch Betts VTL remanufactured by New Century will soon be delivered as will a retrofitted G&L internal splining machine.

The G&L will be delivered after the shop completes its facility expansion. A new welding shop is being added, and the existing welding area will become another machining bay. This, combined with additional office space, will increase the facility’s total space from nearly 36,000 square feet to approximately 58,500. Air conditioning will be added to the entire production area, too.

Mr. Myers says the Wandlers’ openness to make these types of investments is one reason why L&H’s annual business has grown from $10 million to $100 million. He also says this is why the last few years has been the most exciting time he’s experienced at this facility.

Learn about Klingelnberg Corp.

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Top Shops 2012: L&H Industrial

L&H Industrial has a wealth of advanced large-scale machining and manufacturing capabilities.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More