Top Shops 2012: L&H Industrial

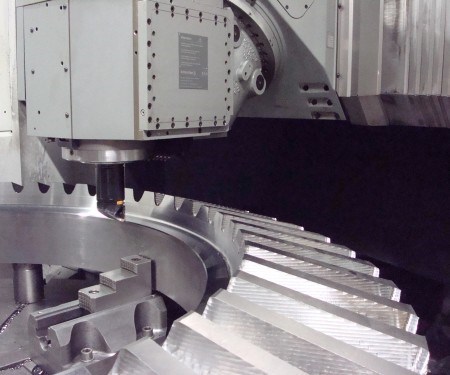

L&H Industrial has a wealth of advanced large-scale machining and manufacturing capabilities.

Share

Developing the Workforce of Today and Tomorrow

Company Description

End Markets Served

- Oil/Gas

- Mining

Workpiece Materials Commonly Machined

- Brass

- Cast Iron

- High-Temp Alloys

- Mild Steels

- Plastics

Contact Information

L&H Industrial

913 L&J Court

Gillette, Wyoming 82718

Related Content

Creating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreMachine Shop Mastery: Insights from America’s Top Shops

Ever wonder what sets Top Shops apart from the competition? Dive into their award-winning practices and explore behind-the-scenes strategies for operational excellence.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More