Machine tool automation is not a new idea at Aztalan Engineering of Lake Mills, Wisconsin. Instead, for this contract manufacturer, using automation to load and unload parts is an established practice. In the 1990s, the company took over production of a set of components from another shop, buying and installing the two robot-loaded CNC lathes this previous shop had used. The cell delivers high productivity to this day.

And yet, the experience with these robots did not mean that the third lathe added to this cell would get a robot of its own. When increasing demand for these components justified a new process involving an additional lathe, Aztalan watched closely to see whether manual loading of this additional lathe was sufficient to keep pace. It was for a while. But when demand was forecasted to increase further, it became clear that a new robot was needed for the latest machine. Therefore, a FANUC M10iA robot has now been added to this

Okuma LB 2000 lathe. Thus, this cell at Aztalan now includes both robots and lathes that are separated in age by nearly 20 years.

The cell is one of various examples of machine tool automation at this company. The extent to which Aztalan uses automation is instructive for various reasons. First, it illustrates the variety of automation options that might make sense in a contract-machining environment. But second, and perhaps more significantly, Aztalan’s experience provides an illustration for why not to be swayed by the challenge of embracing automation. Aztalan faces this very challenge itself. The company is advancing rapidly, and increasing capacity through automation is often the best way to meet production demands. But even so, says Kirk Kussman, company sales and marketing director, automation technologies tend to face extra hurdles when it comes to winning justification. As he puts it, “It’s always hard to purchase a machine that does not directly make a chip.”

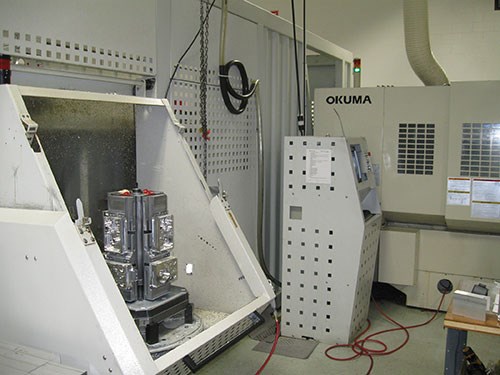

Compounding this challenge is the range of automation possibilities. Succeeding with one automation type does not reveal the value of other approaches. For example, success with the robot-loaded lathes wasn’t enough to show the company the best way to automate a certain manifold-machining process. Here, the best solution was not a robot, but a

Fastems flexible pallet system in conjunction with a horizontal machining center. Rather than coming to this solution on its own, Mr. Kussman says Aztalan embraced it after its machine tool supplier, Morris Midwest, made the case that there was a cost-effective way to automate production of this part number, too.

Building Awareness

Part of the reason why Aztalan is advancing rapidly today is the company’s deliberate decision to do so. About 4 years ago, the company launched a sales and marketing effort aimed at increasing its business volume. The company had little brand awareness back then, but now is more widely recognized, particularly by makers of medical technology—the sector accounting for the largest share of the shop’s business. Within this field today, says Mr. Kussman, Aztalan routinely gets to bid on major RFQs. The company has also succeeded in winning the trust of design engineering firms, a benefit that enables the company to be involved in the development of new products by consulting on their manufacturability.

All of this has led to increased activity. The company has responded in part by expanding, with company CEO Jim Brey himself designing the expansion facility that more than doubled production space when it opened two years ago. The company has also increased staff, along with applying automation to increase the value that staff members can deliver.

An Okuma gantry-loaded LFS twin-spindle lathe is another example of automation that works well within this company’s environment. While Aztalan is a contract shop (meaning much of its work comes from long-term agreements), it still has to be as responsive as a job shop in meeting customers’ often fluid part quantity and delivery requirements. The LFS machine, which features two turning spindles that both face forward, has been valuable for high-volume machining of an automotive part. The overhead gantry not only loads and unloads the part, but also passes it between the spindles for side A and side B machining, keeping multiple pieces in work at any moment. More recently, the shop has assigned a second part number to this machine, and is preparing chuck jaws and grippers for a family of four parts to be assigned to it as well. While the gantry-loaded twin-spindle lathe is an efficient high-productivity resource, it is still a CNC machine with the flexibility this implies—allowing for rapid transitions between different part numbers as needed.

Filling the Time

Something similar could be said of the horizontal machining center, also from Okuma, that is serviced by the pallet system from Fastems. Of the ten pallets with this system, five are set up to run one particular part—a manifold machined from solid aluminum. On each of these five pallets, the tombstone holds eight aluminum workpieces, four blocks for side A machining and four partially machined pieces for side B machining. The remaining pallets are available for production runs of other parts during pauses in producing these manifolds, which are delivered at the rate of about 15,000 per year.

Aztalan could produce this part efficiently using an independent HMC. Even with eight pieces per tombstone, loading one set of parts by hand on one pallet at the HMC while the current set runs on the other pallet could essentially eliminate setup time. However, the next step beyond HMC production is something like the Fastems system. What this automation adds to the already-efficient HMC is the otherwise lost time when no employees are present.

Seemingly, that’s not much time. With two 10-hour shifts, Aztalan captures 20 hours of every work day. And yet, lights-out machining with the pallet system increases the capacity of this HMC dramatically. On a weekday, the pallet system keeps the machine running through the remaining 4 hours. During the weekend, it permits an additional 6 hours of production. This extra 26 hours of machining increases the output of the HMC by more than 20 percent.

Even when staff is present, in fact, the pallet-system-equipped machine is essentially running unattended. Typically, the operator has as long as 6 hours to walk away and tend to other machines before returning to unload finished parts and load new ones.

Keeping Pace

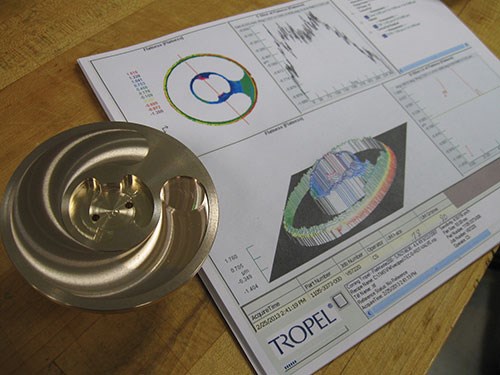

Those robot-loaded lathes—the machines with which Aztalan’s use of automation began—make components for a drug delivery system. Automation in this cell, which now includes the robot added to the newest lathe, frees the cell operator to perform the vital task of inspecting finished parts. The dimensional tolerances of mating components machined in this cell are exacting, with features that even include overall convexity or concavity (depending on the part) of 5 microns.

Aztalan has invested in measurement technology so the inspection required for these parts can keep pace with automated machining. A Tropel form measuring system from Corning uses laser metrology to map finished parts. The device represents a level of inspection technology rarely seen in a contract machining environment.

And this suggests the next level of challenge that automation typically brings. Automated production systems are often so productive that keeping work flowing requires responsive systems both before and after machining. Efficient measurement meets the speed demand after machining. Meanwhile, Mr. Kussman says investing in

Exact JobBoss software—not just purchasing it, but also taking the time to bring its full capabilities into play—has been essential for getting work organized before machining and set up for production more efficiently.

Making the process still more responsive prior to machining is the shop’s main challenge now, he says. The company is searching for ways to expand its CNC programming capacity to keep pace with the still-accelerating workflow. Shopfloor programming will be part of the solution, he says. There is talent on the shop floor, and not every job needs to be programmed in Engineering.

Additionally, the company will learn to rely more on automation within CAM software to generate routine tool paths automatically—but this is not easy, he says. Understandably, programmers want to ensure that every critical feature of a high-value part is programmed correctly. As a result, they prefer to oversee each programming step directly. Thus, it’s one thing to turn out the lights on a machining process, because it’s possible to watch the robot and machine tool in action before the lights go out. But turning out the lights within programming is a different matter, because the software offers no similar way to peer inside. Therefore, adopting CAM automation will entail even greater trust than automated workpiece loading. The machine tool, it turns out, is one of the easier parts of the process to automate.

.jpg;maxWidth=970;quality=90)