Attaining Synergy From Front Office To Shop Floor

By providing a centralized hub of real-time information, ERP software from Global Shop Solutions enables this shop to keep its finger on the pulse of the business. As a result, it can improve accountability, identify inefficiencies that need to be addressed and develop sound strategies for cost reduction and continuous improvement.

Share

Generally, the success of any manufacturing operation boils down to three factors: part quality, delivery speed and price. Decades ago, meeting only two of these benchmarks might have been sufficient. For example, a customer might have been willing to pay more for quick delivery of high-quality parts. In today’s globally competitive arena, however, this is often no longer the case.

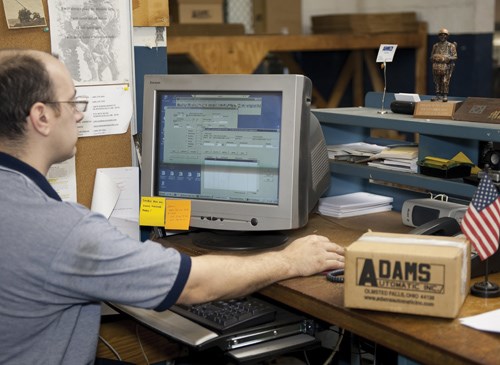

The silver lining is that despite a more difficult environment, modern manufacturers have access to technology that can streamline operations like never before—technology that continues to evolve to provide increasing levels of efficiency. At Adams Automatic, a short-run CNC turning house in Olmsted, Ohio, a customized enterprise resource planning (ERP) system has contributed to sustained growth for almost 10 years. Supplied by Global Shop Solutions (The Woodlands, Texas), the software synergizes all operations from the front office to the shop floor to improve accountability, reduce costs and facilitate on-time delivery and quality ratings in the 99th percentile.

Adams Automatic’s 12 employees produce custom screw machine items for a range of industries, including electronics, valve, aftermarket automotive, medical, and hydraulic. Founded in 1952, the company is now in its second generation of family leadership. Edward Bond, president and CEO, took the reins from his father in 1971, and he has since overseen the transition of the shop into the full-scale manufacturing operation it is today.In fact, the company has expanded four times during Mr. Bond’s tenure. The single-spindle automatics the shop used when he first stepped into a management role have given way to CNC models that produce most parts from barstock. Rounding out the 10,000-square-foot facility are a number of machining and turning centers as well as equipment for secondary work and repair.

Management emphasizes the importance of producing high-quality parts, building relationships with customers by getting things right the first time, and bringing a sense of accountability to every job. This mindset has contributed significantly to the company’s success and expansion over the years, Mr. Bond says. However, accomplishing these goals is not an easy proposition for a shop that takes on such a wide range of different jobs, many of which involve quantities of less than 50 parts.

By providing a centralized point of real-time information, Global Shop One-System Solutions software plays a key role in easing the difficulties inherent to organizing, tracking and improving the shop’s diverse operations at every step of the process from the original estimate to final delivery. "This software has been a big reason for our success," Mr. Bond says. "It has made life easier and really made us more productive."

About a decade ago, things were quite different at Adams Automatic. The custom-written ERP program the shop used at the time was cumbersome and too complex, Mr. Bond says. Even worse, technical support for the system was virtually nonexistent after the developer moved out of town. Seeking a more user-friendly solution, the shop worked with a Cleveland-based consulting firm to determine which software on the market would best meet its needs. "They asked maybe 100 questions and presented us with about 50 different systems," Mr. Bond says. "Global Shop met almost 96 percent of our requirements based on the questions, so the choice was easy."

The shop uses the full range of available modules, including estimating, quoting, shipping and receiving, job tracking, invoicing, inventory and more. Once the shop decides to bid on a job and works out how parts will proceed through the manufacturing process, the quoting module prompts the user to enter information into various categories that affect the quote. These include rates for labor, materials, secondary work, overhead, outsourced operations such as heat treating, and more—all based on the shop’s own pricing structure.

Based on the quote and the chosen manufacturing method, the shop develops binders that accompany every job on the shop floor to keep operators on the same page and ensure consistent quality. The binders contain part blueprints; details about the machines, tools, and workpiece material needed for operations; the number of parts that can be produced per bar; and other process information. The software’s routing procedures track every part as it moves through the process via a barcode system. When a job is finished, employees can use the software to access information needed for shipping, such as how many parts are supposed to be packed in each box.

The modules containing all these data and procedures are interlinked. As a result, disparate areas of the shop that might otherwise be viewed in isolation are instead seen as parts of a whole. With an all-encompassing, real-time picture of the overall operation, the shop can keep its finger on the pulse of the business to improve accountability, identify inefficiencies that need to be addressed and develop sound strategies for cost reduction and continuous improvement.

For example, job tracking enables the shop to compare the actual time it takes to complete an operation to its original estimate. Problem areas are easy to pinpoint, and if the process can’t be improved, future quotes can be adjusted accordingly. Setups are much more efficient, especially on repeat jobs, because operators can update procedures as they go along and incorporate cost-saving ideas. Raw material and finished parts that aren’t shipped are also barcoded and tracked via the software’s inventory module to ensure that the shop is always aware of what’s in stock. "With Global, we can reduce our setup time and minimize our inventories," Mr. Bond says. "If you can minimize your setup time, material costs and handling time, run time becomes less costly."

Pricing information entered during the quoting phase is pulled directly from that module when needed, eliminating redundant data entry and the potential for typos or other mistakes. This helps streamline the front office. All data goes directly from the software into cash flow, income and other financial statements, providing a real-time source of data that the company can track to see how business is coming along. "We print all of our checks, purchase orders and work orders off Global," Mr. Bond says. "A lot of this front office work was done by hand before. That kind of administration labor has been completely eliminated."

As the shop has evolved over the years, the software has kept pace. As an example, Mr. Bond cites its accounting functions, which are more user-friendly than they once were. "As the software grows into an even more powerful tool, we see our shop growing right along with it."

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)