June 2018 Issue

June 2018

Digital Edition

Features

Featured articles from the June 2018 issue of Modern Machine Shop

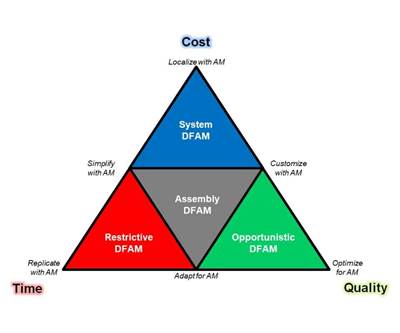

The Many Possibilities of Additive Manufacturing

Why would anyone want to use additive manufacturing?

Read More

Using Augmented Reality on the Shopfloor

As the technology behind virtual reality comes into its own, companies are already looking at how manufacturers can make use of it.

Read More

Good Leaders Have the Difficult Conversations

Talking to someone about their work performance or behavior is never easy, but it must be done.

Read More

MMS Looks Back: 1980s - CAD/CAM Comes on Strong

As CNC machine tools displaced conventional, manually operated machines, computerized systems were taking over other manufacturing functions. This story is part of our 90th anniversary series.

Read More

Characterizing the Future of Manufacturing over the Next Nine Years

The hopes and dreams we have today provide a good clue for what tomorrow might be like.

Read More

MMS Looks Back: 2000s - Machine Shop Connectivity Increases

A machine shop’s experience installing Wi-Fi in 2005 is just one illustration of the rise of wireless technologies and the expectation of 24/7 connectivity. This story is part of our 90th anniversary series.

Read More

MMS Looks Back: 1930s - Machine Shops Take a Belting in the Depression

Even when harsh economic conditions have business at a creep, manufacturing methods and shopfloor practices must move forward. The means of powering machine tools is a case in point. This article is part of our 90th anniversary series.

Read More

Asian Trade Shows Reveal Focus, Unbridled Optimism

While South Korean builders continue to push more advanced technology, newcomers from China seem eager to sell in North America.

Read More

MMS Looks Back: 1970s - When We Looked Back and Forward

One article in the 50th anniversary issue recapped the emerging technologies covered in years past, but another predicted how the digital computer and automation might impact our industry in the future. This story is part of our 90th anniversary series.

Read More

How to Get Form Measurements Right, Part 2: Avoiding Measurement Mistakes

Avoid these five form-measurement mistakes.

Read More

Being Part of Modern Machine Shop's Brand Evolution

The Modern Machine Shop brand has changed, expanded and improved in thoughtful ways during the near decade and a half that I’ve been part of the MMS team. Here are just a few examples.

Read More

Metalworking Index Sustains Growth Rate Entering the Second Quarter

Metalworking’s April reading remained unchanged from the prior month.

Read More

Cloud-Based ERP Consolidates Quoting, Enables Mobile Management

E2 Shop cloud-based enterprise resource planning software from Shoptech improved the quoting process at an Ohio machine shop and enabled off-site management.

Read More

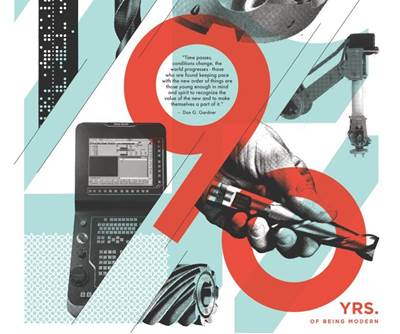

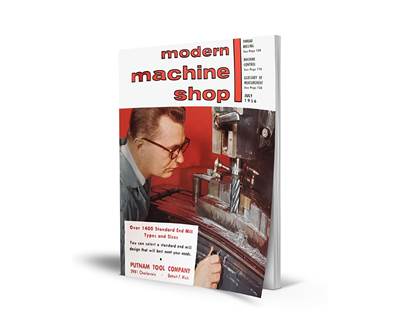

A Celebration of Serving Manufacturing for 90 Years: MMS Looks Back

A brief history of Modern Machine Shop and its contribution to the industry.

Read More

An Introduction to Our Collection of Articles Celebrating the Magazine’s 90 Years: MMS Looks Back

We consider technologies that have been important through each of our nine decades so far.

Read More

MMS Looks Back: 1940s - How They Rolled During World War II

What has changed in roller bearing manufacturing? The Timken Company and Modern Machine Shop reunite to explore the topic we covered 75 years ago. This story is part of our 90th anniversary series.

Read More

Even My Accurate Predictions Are Wrong

The future does not come in a straight line. Multiple factors affect one another and the final outcome. My prediction that machine shops would see more composites is playing out, but I missed an important means by which this would happen.

Read More

Understanding Circle-Segment Milling Tools

The circle-segment cutter represents a class of milling tool in which the CAM software is key for using the tool effectively. Cutting profiles presented at the proper angles realize cycle-time reductions in contoured workpieces such as molds. A CAM company engineer discusses the role of this tooling.

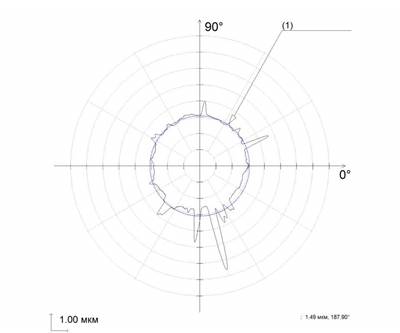

Read MoreHolding Size with Tight Tolerances

Tolerances of less than 25 microns can be challenging to achieve and hold. Here are some suggestions for holding them for multiple workpieces.

Read More

MMS Looks Back: 1960s - The Radical Becomes Practical

Stories about whether to adopt numerical control reveal the value of careful consideration over wholehearted embrace or outright dismissal of new disruptive technologies. This story is part of our 90th anniversary series.

Read More

MMS Looks Back: 1950s - NC? What’s NC?

Numerical control was first mentioned in the pages of Modern Machine Shop in the mid-1950s. It proved to be the biggest disruptive machining technology of that era—maybe even the biggest disruptive technology ever. This story is part of our 90th anniversary series.

Read More

Overcoming the Limits of Hard Milling with EDM

An unusual opportunity led a maker of die-cast dies to reconsider its emphasis on hard milling and take another look at its use of EDM.

Read More

MMS Looks Back: 2010s - How Far Will Digital Advances Go?

Shops now linking their capabilities into unified systems are taking the first steps on a journey with no known destination. In media, too, we are asking our own version of this question. This story is part of our 90th anniversary series.

Read More

10 Lean Manufacturing Ideas for Machine Shops

In addition to the right mix of traditional strategies, a lean manufacturing toolkit can make high-mix, low-volume machining faster, more predictable and less expensive.

Read More

.jpg;maxWidth=300;quality=90)