Alter the Axial Depth

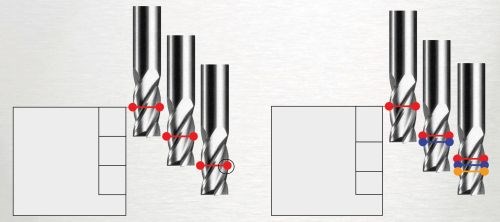

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. The solution: Change the axial depth of cut for each pass.

Share

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. Early damage to the tool can, therefore, occur at this one spot. The tool might have to be changed because of the wear at this one spot, even though the rest of the tool’s flute length is sharp.

The solution: Change the axial depth of cut for each pass. This will distribute the problem area to different points along the tool, as the drawing above suggests.

This practical advice is one of 10 tips for machining titanium recently provided by cutting tool supplier Stellram.

Related Content

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.png;maxWidth=300;quality=90)