Advancing to Micromachining on a CNC Swiss Lathe

By moving up from a standard lathe to a Swiss-type machine, this company can now bid on making small, complex parts it wasn’t able to in the past, while also slashing cycle times on legacy parts.

Share

The best thing about keeping a file of bids you couldn’t quote in the past due to part complexity and the limits of your shop’s capabilities is that, once you do invest in the right equipment, you can revisit that record and hopefully win the bid the second time around. That’s what Sussex Wire has been doing since purchasing a CNC Swiss-type lathe for micromachining production parts as well as making small-batch prototype runs.

Having used standard turning machines for years, the company is now reaping the benefits delivered by this more advanced technology with signature sliding-headstock design including the ability to perform both turning and milling; machining parts complete using the main and subspindles; reduced cycle times; savings from being able to buy smaller diameter barstock; and the ability to perform unmanned machining. Plans are already in place to begin lights-out machining in the near future.

As there often is with any new technology or machining process, there was a learning curve for Sussex Wire, with challenges that included using programming codes that are specific to Swiss machines, working with stock materials and workpieces even smaller than it had in the past, and finding experienced operators for a process that’s unlike any other. Although the new machine has been on the shop floor for less than a year, these challenges have been overcome, and the machine’s potential continues to be revealed with each new part that’s run across it.

Learning Swiss

Founded in 1973 and located in Easton, Pennsylvania, Sussex Wire specializes in designing and manufacturing highly engineered parts and components for markets including medical, semiconductor, automotive, energy, aerospace and the military, among others. The company is known primarily for its expertise in cold forming, which involves transforming metal wire and specialty alloys at room temperature into precision micro-miniature components. This method is faster and more cost-effective than machining many of the parts the shop produces, but not in every instance, in which case it would turn to its turning machines. Yet, although these older machines were still making parts well within tolerance, they were somewhat slow and limited in terms of their capabilities, so the company decided to invest in the latest CNC Swiss-type technology.

The shop was drawn to this machine platform for a number of reasons. Unlike conventional lathes on which the part is stationary and the tool moves, a Swiss-type turning center allows the part to move in the Z axis while the tool remains stationary. The barstock is held in the machine and advanced via sliding headstock through a guide bushing. Only the portion being machined is extended from the guide bushing, allowing the material to be held very near where the tool is cutting, and therefore minimizing deflection and increasing accuracy. This requires ground stock, which has a more uniform diameter and will not jam in the guide bushing. Some models enable the guide bushing to be removed, so shorter, stockier workpieces can be machined that do not need support.

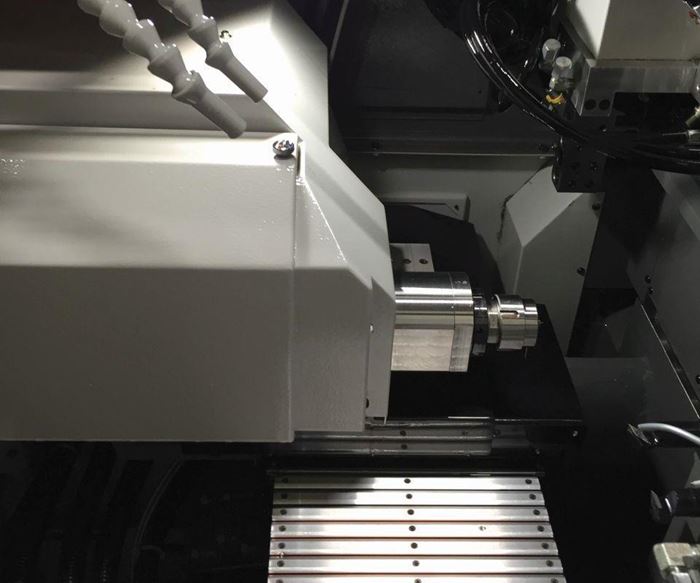

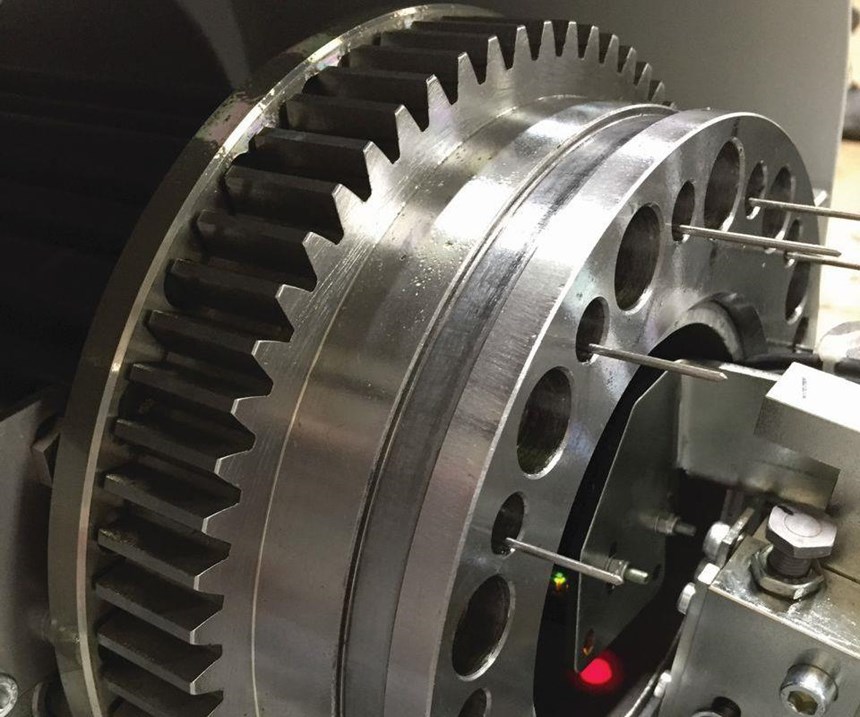

When Sussex Wire decided to move to a Swiss-type, Darryl Sienicki, senior tooling designer, was assigned the responsibility of researching machines currently available in the United States and their capabilities, and determining the make and model that would best suit the company’s needs. After comparing the time required to produce certain legacy parts on the shop’s existing machines to that of four brands under consideration, Mr. Sienicki and his colleagues chose a Marubeni Citizen-Cincom (Cincom) L12-type VII Swiss turning center. The lathe has a maximum barstock diameter of 12 mm, a maximum machining length of 135 mm (ground bar) or 30 mm (non-ground bar), and a spindle through-hole diameter of 20 mm. The maximum main spindle speed is 15,000 rpm for ground bar and 12,000 rpm for a non-ground bar, while the maximum subspindle speed is 10,000 rpm. As many as 28 manual tools can be mounted at a time. Of those, the L12 has four live tools on the main spindle side of the machine that can perform cross milling, cross drilling and slotting. There is also an optional three-position live spindle that can accomplish face drilling and face milling, along with angular hole drilling. The subspindle side of the machine also has four live tooling positions for face drilling and face milling. An optional slotting saw unit can be put into one of the four live tool positions. The machine can also perform deep-hole drilling on the main spindle through the use of a fixed-drill tooling station located on the subspindle housing.

As for options, Sussex Wire decided to invest in a high-pressure coolant system with 10 lines, primarily for clearing chips off of the workpiece, but also to help stabilize the temperature of both the part being machined and the cutting tool during operation. It also opted for a Cool Blaster mist-control system for filtering cutting fluid mist from the work area, which can be unhealthy when aspirated, and a fire-suppression system for future lights-out machining. Once barstock has been loaded into the back of the fully enclosed guide tubes, the Swiss-type’s hydraulic feed system delivers maximum speed of 12,000 rpm, while the LNS Tryton bar feeder with “combo barrel” design performs across the total range of 0.039 to 0.500 inch without barrel changes. The bar feeder is suited for small-diameter stock because each of the bars resides in its own tube, or barrel, so that they do not need to be separated when they enter the feed mechanism as they do in a magazine-style feeder.

Once installation of the Swiss-type was complete—in this case requiring technicians from Cincom distributor Precision Machine Tool Solutions (see the sidebar below), LNS, and Firetrace, the manufacturer of the fire-suppression system—onsite training began, through which the technicians provided operating tips and troubleshooting suggestions.

Challenges and Benefits

Swiss-type machines are known for their sliding headstock and the ability to machine intricate, geometrically complicated pieces in one setting by delivering the workpiece to the cutting tool, instead of the reverse. Since this was Mr. Sienicki’s first experience with a Swiss-type, he wanted to learn how to run the machine himself before hiring an experienced operator. He took what he’d learned during training and first began running simple parts, increasing the part complexity as he became more comfortable with the machine. This progression came about fairly quickly, thanks in part to the Cincom front end software system backed by the Mitsubishi Meldas 70LPC CNC. The system is designed to be user-friendly and features multi-line, multi-axis programming along with superimposed and synchronized control. While he was gaining confidence in running the machine, the company began searching for Swiss lathe operators, eventually hiring two with a wealth of experience in both programming and operating these types of machines. This eliminated the need to contact an outside technician whenever there was a question to be answered or a challenge to be overcome.

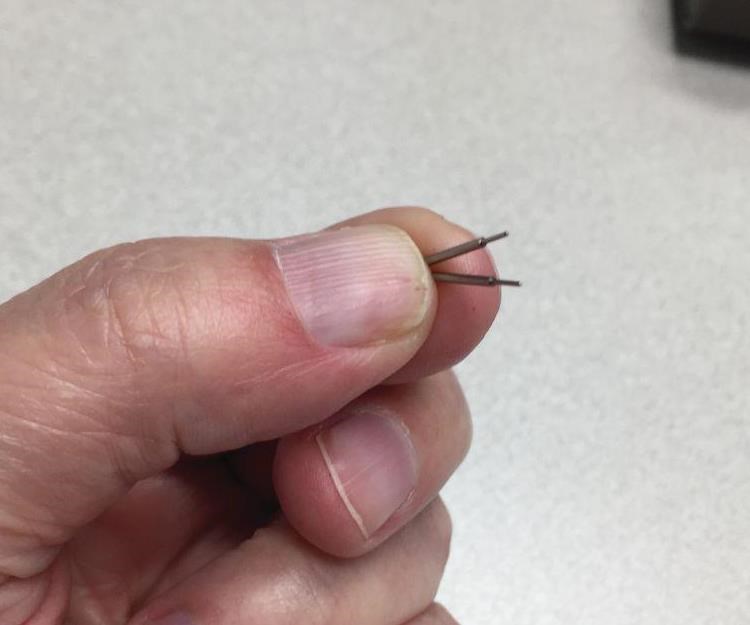

There were additional hurdles, however, as even an experienced operator of CNC HMCs and VMCs would need to learn certain G-code commands that are specific to Swiss machines in order to keep motions in sequence. Such commands include the wait code that synchronizes the main spindle and the subspindle, which are programmed individually, and tells each device when to pause and cease rotation to avoid a crash. Mr. Sienicki continues discovering ways the machine’s two spindles can be used in conjunction with one another on certain processes for increased productivity. For example, one of the company’s current jobs for an application in the electronics industry involves machining a 1-mm thread with 0.25-mm pitch, so it is using the subspindle as the tailstock for support during threading of the part by the main spindle. Without this ability, Mr. Sienicki believes this part may have been added to the “no quote” folder.

Another point about the move to Swiss-type straddles the line between being a challenge and a benefit, in that—although it’s the very definition of micromachining—tiny parts can be harder to work with than larger parts. Features can be more difficult to machine on smaller workpieces, while at the same time purchasing barstock for smaller workpieces is less expensive than for parts with more standard dimensions (the vast majority of the parts Sussex Wire produces are a 0.25 inch and smaller) and more of the bar is often left as a remnant and can be used on other machines for different purposes. Additional benefits Sussex Wire has realized include:

-

The ability to produce net-shape parts on one machine, in one operation, with live tooling and backworking.

-

Realizing the company’s new capabilities, existing customers have started requesting bids for parts they haven’t sent to Sussex Wire in the past.

-

Quick setups on the Swiss-type enable smaller batches, including prototypes, which a customer might wish to purchase in smaller lots to test before placing larger orders. Productivity also is improved by software, which speeds up the process setup. Programmers can watch a part run in simulation and change it if they don’t like what they see. All the setup technician has to worry about is putting in the tools, touching them off correctly and pressing cycle start.

-

The length-to-diameter ratio is extended on a Swiss-type because of the way barstock is fed into the machine, with plenty of stability and support provided by the guide bushing.

Most importantly, the machining time required by the company’s old lathes on a series of legacy parts were slashed once they were being produced on the Swiss machine. In a series of case studies, Mr. Sienicki found that 1) traditional machining of one part required four processes and took 150 seconds, while the Swiss-type machine did the same job in one process in 45 seconds; and 2) traditional machining of another part required five processes and 200 seconds, while Swiss machining delivered the same part with one process in 85 seconds. Traditional turning also required manual loading/unloading and an inspection operation between each run, while the Cincom is self-loading and provides such accuracies that just one inspection after machining and a final inspection before shipping are required.

Quoting with Confidence

Even though the company has learned a lot about its new Cincom Swiss-type lathe over the past months, plans to continue exploring its capabilities—and even upgrading them—are ongoing. For one thing, the machine is capable of being run in “convertible” mode, meaning the guide bushing can be removed to allow for wider diameters of barstock and to perform operations like a conventional lathe. This works well with thicker stock that has a length-to-diameter ratio smaller than 3-1, since there is enough material to provide support without the guide bushing. This capability will be called upon should a job with a larger part be awarded to the company, Mr. Sienicki says.

As for detecting tool wear or breakage, while the machine can’t physically change its tools, it can sense a problem with a cutting tool and stop running so that any other tools using the same cut path will not be damaged as well. The machine also has the capability to move to another tool position with an identical tool when one becomes worn, but only at a predetermined interval within the program, basically maximizing the run time.

Probably the biggest benefit the company has realized from the move to a Swiss-type turning center, at least from Mr. Sienicki’s perspective, is “the ability to quote with confidence,” knowing that customers will be satisfied, tolerances will be met, and Sussex Wire can continue growing into new and existing markets, he says.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=970;quality=90)