Additive Manufacturing — More Than Metal: How Vat Photopolymerization Started It All

Vat photopolymerization was the first additive manufacturing process to be successfully commercialized. Three decades later, this technology has shown how AM is capable of scaling to volume production and making custom products on demand.

Share

Vat photopolymerization’s high resolution makes layering effects almost invisible, as seen in this side-by-side comparison of a Vortic watch case printed on a FormLabs Form2 (clear) and laser powder-bed fusion (metal). The vertical lines still remain, however, due to tesselation effects when converting from CAD to STL file format. Photo: Timothy Simpson

Powder-bed fusion (PBF). Directed energy deposition (DED). Binder jetting. How many additive manufacturing (AM) processes are there?

ASTM/ISO standards define seven basic AM processes, which include the three that I have discussed in previous columns as well as vat photopolymerization, material extrusion, material jetting and sheet lamination. While PBF and DED are the most prominent methods for metal AM right now, we are going to take a quick dive into each one of these other processes so that you are aware of their capabilities and potential for use in your company.

I’ll begin with vat photopolymerization because it was the first AM process to be successfully commercialized. This process was introduced to the market in the late 1980s by 3D Systems and called stereolithography, based on Chuck Hull’s patent for the technology. Even though others had invented aspects of the technology earlier, Mr. Hull is credited by many as “The Father of 3D Printing” because he was the first to bring the technology to market. Thirty years later, he remains very active in the industry, serving as CTO for 3D Systems and deriving new AM technology from his initial patent application (see 3D Systems’ Figure 4 factory solutions).

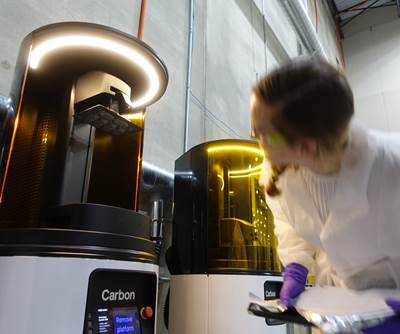

Vat photopolymerization uses a light source to activate a photopolymer, which is basically a liquid “goo” that hardens when hit by the right wavelength and intensity of light. Early systems had a large vat of liquid photopolymer (hence the name) that was selectively hardened by a laser layer-by-layer to form the part. Material advancements now enable digital light projection (DLP) systems — the same ones used to project movies on your wall from your computer — to initiate the cross-linking that hardens the polymers into a solid object. DLP systems are significantly faster than laser-based systems because you can solidify a whole layer at once versus waiting for the laser to trace and fill in the image in each layer. This is why newcomers like Carbon can additively manufacture soles for Adidas so quickly. Its patented Continuous Liquid Interface Production (CLIP) technology enables its systems to look like they are pulling a part out of a puddle just like you might see in a movie. If you haven’t seen this technology in action, check out Carbon CEO Joseph DeSimone’s TED talk in which one of the company’s systems additively manufactures a part during his 10:43 minute lecture.

Where can you find this 30-year-old AM technology? It has become commonplace in quite a few places now. While Adidas is ramping up production of its FutureCraft 4D shoes via Carbon’s AM platform, Invisalign has been using 3D Systems stereolithography machines to make molds for custom braces for decades. The company reportedly makes more than 320,000 parts per day, showing that AM technology can be scaled to higher volumes when there is a good business case. Not surprisingly, many dentists’ offices are now buying and using vat photopolymerization systems to additively manufacture custom crowns, dentures, implants and more directly in their offices using Food and Drug Administration-approved AM materials. Meanwhile, companies like Sonova are using EnvisionTec’s vat photopolymerization systems to additively manufacture custom hearing aids, transforming the hearing instrument industry thanks to AM’s ability to produce custom parts on demand with very high resolution.

While 3D Systems, Carbon, EnvisionTec and others are chasing production-scale systems, companies like FormLabs have shifted the discussion to the other end of the spectrum, namely, affordable desktop systems for everyday users. FormLabs launched on KickStarter, a crowd-funding website designed to help bring fledgling projects and a lot of start-ups to life, and quickly raised nearly $3 million. They were inundated with orders, which led to numerous delays as they ramped up production, but they ultimately succeed in bringing vat photopolymerization to desktops (you can learn the story of FormLabs and other AM start-ups in the documentary, Print the Legend). Their boxy amber-covered silver systems are becoming ubiquitous, and I find one in nearly every makerspace that I have visited. Meanwhile, they have continued to raise venture funding, develop new materials and launch improved systems. They recently introduced their third-generation system, the Form3 and are offering materials such as “Tough,” which has all sorts of uses for tooling, fixtures and jigs in machine shops and on the factory floor. Recently, they even partnered with Gillette for RazorMaker, allowing users to additively manufacture custom razor blade handles on their systems before being made available on-demand to other consumers.

As the first additive manufacturing process, vat photopolymerization has come a long way the past three decades. It offers the highest resolution of many AM processes. In many parts, it is nearly impossible to see the layering or staircasing effects that plague other AM processes. Build volumes continue to get bigger, and the latest advancements in software and hardware, combined with new advancements in materials, have opened new avenues for commercialization and profitability. Producing consumer items such as braces, crowns, hearing aids, razor blade handles and soles for your running shoes, vat photopolymerization has shown us that AM is capable of scaling to volume production and making custom products on demand — and sometimes at the same time. How many manufacturing technologies can claim that distinction?

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Injection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)