Share

It is a truth universally acknowledged that the more finicky the process, the more frustrating it is to automate. Deburring can be a particularly challenging process to automate, as predicting the distribution of burrs is far from an exact science. After all, if the shop could predict the locations of burrs accurately enough to easily automate deburring, then it would probably just eliminate the burrs.

Norton Saint-Gobain — an abrasives manufacturer with a global footprint — is well-acquainted with the challenges of automated deburring, as well as the growing demand for automated abrasive solutions. With no one-size-fits-all solution in sight, the company has opted to help manufacturers develop automation solutions for abrasive processes through its in-house automation lab.

A Methodical Approach to Abrasive Automation

The APS automation laboratory is located at the Higgins Grinding Technology center in Northborough, Massachusetts, within one of the company’s five R&D centers spread around the world. The R&D lab located on-site is dedicated to the methodical analysis of abrasives to develop an improved understanding of processes like creep-feed grinding and addressing challenges like chatter.

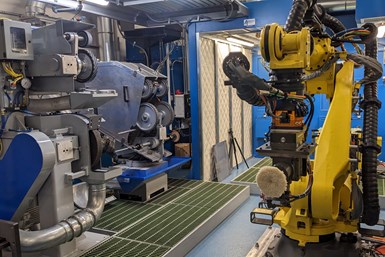

The APS lab’s testing room has three distinct work stations: two custom machines designed for part-to-media applications (left) and a worktable for media-to-part applications. The FANUC robot arm pictured attends all three stations.

In February of 2022, the company opened its Abrasive Process Solutions (APS) lab in the same building, dedicating it to developing automation processes on behalf of automation integrators and customers, often at no expense to the participating companies. Norton Saint-Gobain built this lab with the intention of completing two projects per month and completed 23 projects that first year, maintaining its pace since.

According to APS Manager Tony Landes, the goal of the lab is to prove the viability of automation solutions both for the benefit of users and to improve the company’s own knowledge base. “Our job is to decrease the risk for integration partners,” Landes says, “but we also feel that developing automation for abrasives is a net gain for us. It gives us the chance to test abrasives using real-world applications.”

These custom machines are designed to test applications in which the part must be moved into contact with media that remains in a fixed location. Norton Saint-Gobain designed these machines to work with a wide variety of media to test as many solutions as possible.

The APS facility has an observation room and a testing room, the latter of which includes three work stations: two custom machines for part-to-media applications (automating a process by moving the part to an abrasive media that remains in place) and a multi-axis table for media-to-part applications (automating by moving the abrasive to a part fixtured on a table). The lab uses a FANUC R-2000iC robot arm capable of lifting 210 kilograms to perform tests at these stations. The different stations enable the lab to test multiple approaches to automation based on the requirements of the partner who requested the service. During tests, cameras record all processes for review, and the observation room has multiple monitors for viewing results. The lab is also equipped with a 3D printer for quickly and economically creating custom fixtures.

“Our job is to decrease the risk for integration partners.” – Tony Landes, APS Manager, Norton Saint-Gobain

Application engineers determine which abrasives to use, as well as the spindle speeds, stepovers, cycle times and compliance (the control over applied force in the grind zone — an important consideration for using abrasives). They engineer and test multiple approaches and record the results, relying on years of experience with customers to guide their approach. “We’ve been in and out of facilities for years,” says Landes. “We’ve seen it done well, and we’ve seen it done poorly.”

Landes says the APS lab tries to screen applicants to ensure the lab uses its capacity wisely. “First we ask if it’s possible,” he says. “For example, if parts are somewhat consistent coming in, that makes it much easier and more viable to automate. Then, is the company ready to invest or just dreaming?” After screening the applicant, the APS team tackles the challenge of developing a solution.

But not every round of tests results in the desired outcome. One request was to remove five pounds of material per minute using a 40-horsepower machine and abrasive wheel, which Applications Engineer Nathan Jackson says was simply not possible. “Through testing, we proved that the proposed process wouldn’t work, and now the customer is looking at a much more viable 70-horsepower machine with coarse-grit abrasive belt,” Jackson says.

The lab often brings in the end-user for a consultation and demonstration of the final process. “That way we can be sure they understand our findings and can make the best use of our advice,” Jackson says.

Let’s take a look at one of the APS successes.

Automating Gear-Tooth Deburring

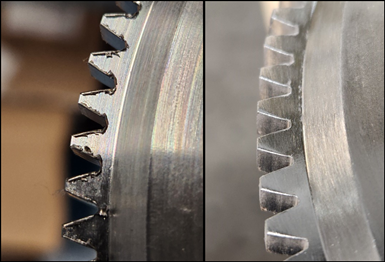

After being contacted by an integrator, the APS lab took on the job of developing a process for removing heavy burrs from the edge of a gear piece, followed by a gentle chamfer. The challenge here, as with most deburring automation, was to remove these burrs without taking off so much material that the part falls out of tolerance — an especially difficult task with gears, as the teeth must precisely match their paired components in the final assembly.

The lab used a 120-grit, aluminum oxide flap wheel to perform an initial pass, deburring the gear teeth. To avoid removing too much material, it used a 300-rpm part rotation against the 2500-rpm rotation of the flap wheel, which successfully removed the burrs without damaging the finish. Photo Credit: Norton Saint-Gobain

APS Senior Application Engineer Mike Shappell spearheaded this task, eventually developing a two-step process. The solution involved first using a Norton abrasive flap wheel for deburring, followed by a Sunburst bristle disc brush applied to each side of the gear to achieve the desired finish.

To set up the flap wheel, the lab mounted the gear on a spindle motor with an active compliance device to control the applied force during the process. Then, it ran the 120-grit aluminum oxide abrasive flap wheel at a slower speed than normal to remove the burrs without removing too much material. Eventually, the lab found that a 300-rpm part rotation turning against the 2500-rpm rotation of the flap wheel provided the necessary material removal rate while maintaining the surface finish required for a final step.

“The next step would be considered the most critical,” Shappell says, “as the smoothness of the gear edges is critical for how they work in conjunction with the other moving components of the device being driven.” To minimize material removal while producing the desired smooth edge, the lab opted for a 4.5-inch diameter, 50-grit Sunburst bristle disc brush and a connector with a ⅝"-11 thread pitch. “The ⅝"-11 attachment method is handy for heavier-than-normal processes, as well as the use of tool holders such as BT30 type tools,” Shappell says.

After deburring the outer face of the part, APS used a Sunburst bristle disc brush to finish both faces. Here we can see the “stacked” bristle-brush setup, which enables the robot arm to minimize movements to reach the back of the gear. Photo Credit: Norton Saint-Gobain

While the original machining process ensured that the burrs would be on only one side of the gear, both sides would need finishing passes with the Sunburst brush. For the test, the lab “stacked” two bristle brushes back-to-back so that the spindle could simply move past the gear to get the rear-facing brush into position to finish the back face of the gear. Shappell says this setup was designed to avoid the need to program large motion adjustments on the robot arm.

As with the deburring pass, the lab ran the part at 300 rpm against the rotation of the brush, which ran at 2100 SFPM — first clockwise, then counterclockwise. The cycle time was only 20 seconds in each direction for each face of the gear, or 80 seconds total. The process kept to a 2-millimeter engagement both to provide the needed finish and to prolong the life of the abrasive brush.

The lab passed the specs of this test on to the integration specialists, including the abrasives used, compliance, engagement and speeds. This information in hand, they could design an automated cell for their customers much more quickly and with confidence in its ultimate success. For Norton Saint-Gobain, this is the ideal result.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More