A Sampling of Advanced Technologies at FANUC

Here are some of my impressions about the technologies I saw during a recent trip to FANUC’s headquarters in Japan.

Share

In April, I visited FANUC’s expansive campus located near Mount Fuji in Oshino-mura, Yamanashi, Japan. The company hosted an open house and factory tour that offered a sneak peek at some of the new technologies it will highlight at IMTS in September as well as later in the year at JIMTOF in Japan. Below are a few impressions about what I saw at the event.

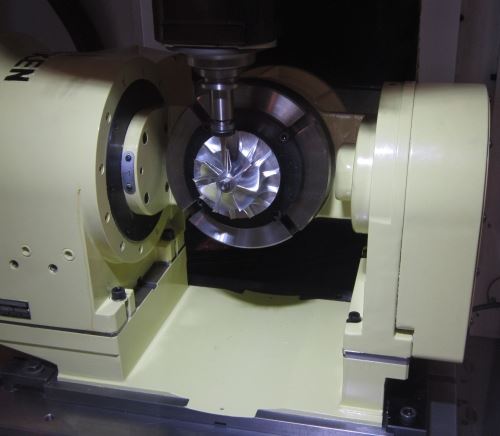

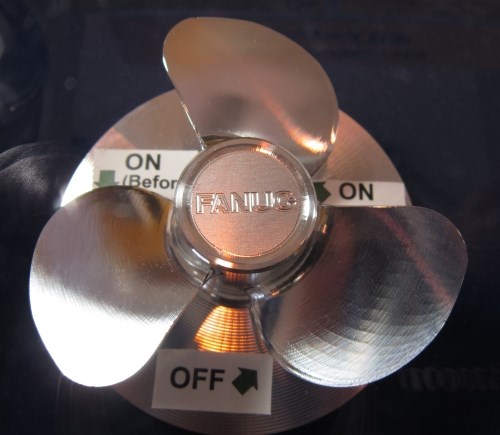

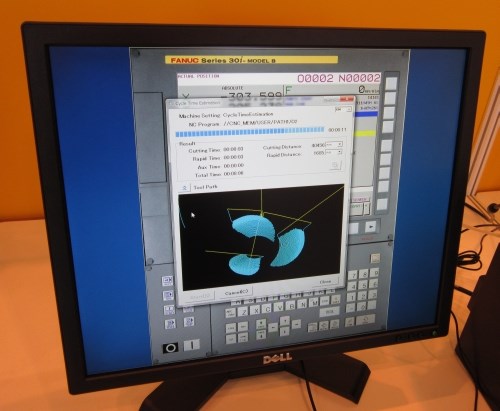

• Robodrills are more than drilling and tapping machines. “Robodrill” is seemingly a misnomer for FANUC’s so-named line of small-footprint machining centers. At this event, a number of these machines demonstrated sophisticated four- and five-axis operations for parts such as propellers, turbine blades and turbocharger impellers. A variety of new control functions, which are available on any FANUC-controlled machine in the market, enable improved surface finishes and machining speed for such applications. One of these is High Speed Smooth TCP (tool center point) rotational-axis compensation featured on machines using the company’s Series 30i-Model B and 31i-Model B controls. This automated feature generates a tool center point path that (using either the tool tip or the entire length of the tool during side-cutting operations) creates fine surface finishes during five-axis machining. The feature includes the functionality of TCP control, Tool Posture Control and other algorithms that smooth tool motion while finessing tool posture.

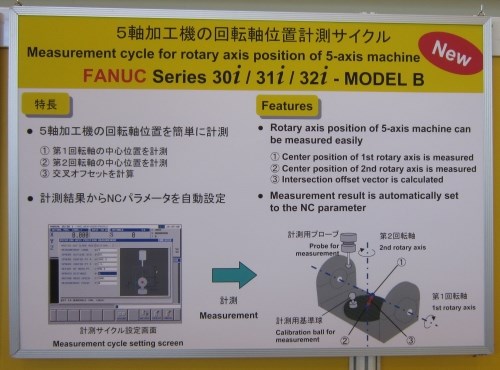

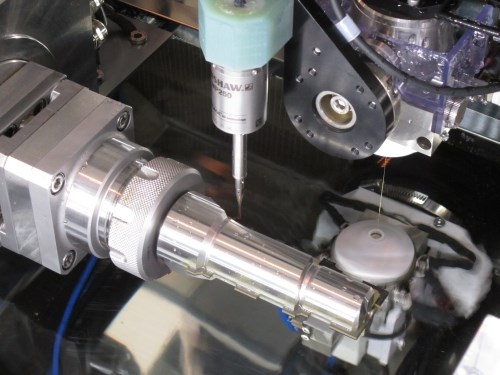

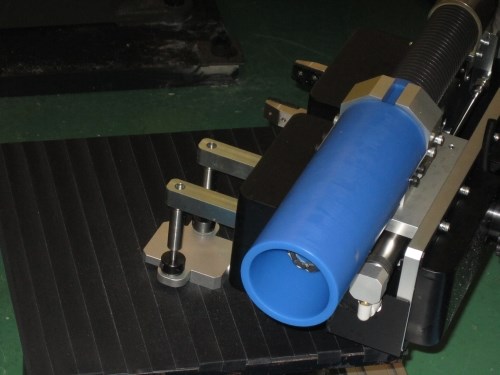

• Use of on-machine probing is increasing. Another sign that Robodrill machines are being designed for more sophisticated applications is the use of on-machine probing. One example is a new measurement technique that determines the actual rotary-axis position of a five-axis machine. Using a spindle-mounted touch probe and calibration ball installed on a Robodrill’s rotary table, the center position of the A and B axes is measured, and the accompanying intersection offset vector is calculated. Position offsets are then automatically sent to the CNC to ensure accurate machining. Of course, this measuring cycle is also available on all brands of FANUC-controlled machine tools. FANUC also demonstrated in-process probing on a Robocut wire EDM with rotary table to ensure accurate wire cutting of PCD inserts brazed onto tool bodies. In addition, the company unveiled its Nanochecker 3D probing and position compensation system used on its new Robonano machine. The five-axis Robonano can perform milling and turning operations to create tiny features for precision components such as lens arrays. In-process probing is critical to ensure the accuracy of not only individual feature geometry but also feature-to-feature position for such tight-toleranced components.

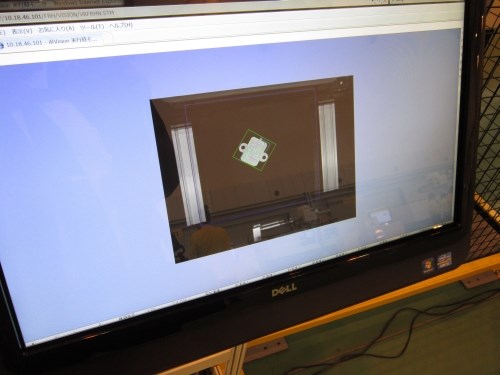

• Robotic vision systems are improving. In one of many automation demonstrations at the event, an M-20iA robot serving two Robodrills used position and orientation data gathered by a 3D vision system to remove parts randomly located in a bin. (Click here to see a video of this demo.) To begin a new cycle, the 3D vision sensor mounted high above the bin measures the entire bin contents to detect individual parts in three dimensions. A vacuum device on the robot arm then pulls an identified part from the bin and drops it on a fixtureless staging station. An overhead 2D camera next determines the orientation of that part on the staging station to enable the robot to grip the part and deliver it to the first Robodrill for OP10 work. Parts moved to and then completed on the second Robodrill are finally delivered to a conveyor that transports them out of the cell.

• Laser cutting functions have been added. In 2010, FANUC unveiled its Laser C Series that pairs a FANUC CO2 laser with the company’s Series 30i/31i-L Model B CNCs. Designed for both cutting and marking operations, the C Series is available in four versions ranging from 1 to 6 kW. The laser line has been upgraded to include various oscillator control functions such as minute laser output calibration, features to shorten piercing time and a power consumption monitor that displays in real time the amount of power the machine consumes as it operates.

• FANUC applies its own equipment. When visiting equipment OEMs, it’s interesting to note the extent to which a company uses its own equipment to manufacture its products. Not surprisingly, FANUC applies automation in a big way, using 2,500 of its robots at its expansive manufacturing campus. In fact, its sheet metal fabrication, welding and powder coating facility is automated to the extent that only three people are needed in that building.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More