A Compact but Rigid VMC for Machining Titanium Blades

In recent years, machine tool builders have developed models specifically designed for the efficient machining of titanium and other hard metals.

Share

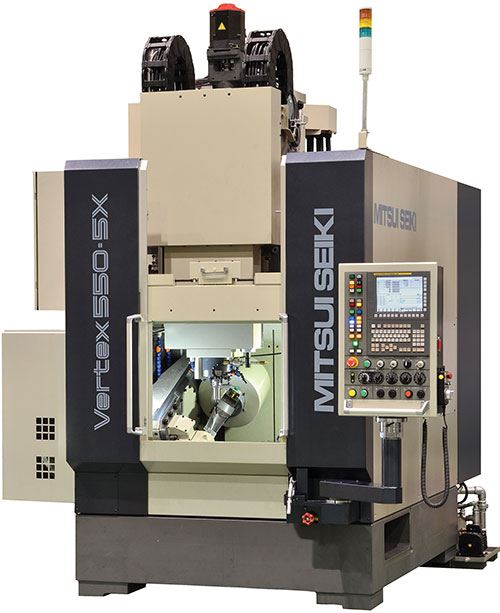

In recent years, machine tool builders have developed models specifically designed for the efficient machining of titanium and other hard metals. Machines for very large aerospace parts have been especially notable. However, builders such as Mitsui Seiki (Franklin Lakes, New Jersey) have not overlooked the need for more compact machines that handle smaller titanium parts such as turbine blades for aerospace and power generation. The company’s Vertex 550-5XB is an example of a machine targeted to this market.

This machine occupies 65 square feet of floor space and has travels of 550, 600 and 500 mm in the X, Y and Z axes, respectively. The five-axis VMC addresses many of the same design considerations that characterize larger machines suitable for titanium, but exhibits some significant exceptions, too. A close look at this class of machine is warranted because the advantages of a smaller, application-specific system may be less apparent than in the case of a larger machine. In other words, prospective users will want to know why they need a special machine for titanium instead of a special-purpose machine.

According to Mitsui Seiki, the design criteria identified for this class of machine include a small footprint, the ability to rough and finish parts in one setup, and the capability to achieve high accuracy and improved surface finish. Also required are competitive cycle times and attractive capital cost per part.

Regardless of size, all machines for titanium work must be designed for high rigidity. A rigid machine structure is the foundation for minimizing vibration, which is especially problematic when machining titanium, because spindle speeds tend to be lower and feed rates higher than when machining in aluminum and mild steel. This creates the potential for low-frequency harmonics that produce chatter, and chatter quickly wears the sharp edges on cutter flutes that titanium requires, leading to poor tool life. Designers of large machines generally opt for weight and mass in machine structures to counter this tendency. The same strategy is also effective for a small machine. For example, the Vertex 550-5XB features a single-piece cast bed and a box-in-box design engineered for stiffness while retaining its small footprint.

Likewise, guideway mounting surfaces are hand-scraped because this technique, although more costly, enhances volumetric accuracy and improves vibration damping. The rotary axes are also engineered for accuracy and stiffness. This machine features an unusual rotating/tilting table that balances mass for smooth motion in the A and B axes. The A axis tilts from 0- to 90-degree angles, and the B axis offers 360-degree rotation in 0.001-degree increments. The configuration of the rotary axes is ideal for producing turbine blades from forgings, castings, barstock or solid billets. The design of these rotary axes enables automatic load/unload options such as an articulated arm robot or overhead gantry-style robot. These options make it suitable for placement in a cell or flexible machining system.

Finally, the spindle is designed to maximize bearing support nearest the spindle face and thus minimize this source of vibration. Because the spindle head does not provide a rotary axis for positioning, it can be built more robustly for high thrust forces and high rigidity. Several toolholder interfaces are offered, although HSK is recommended.

For turbine blade production, many manufacturers will find the investment in a VMC designed for this application to be easily justified, especially considering the volume of blades expected to be consumed by aerospace and power generation into the foreseeable future.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

-(1).jpg;width=860)