A Big Move to Small-Parts Manufacturing

By using GibbsCAM software, Progressive Tool was able to change from large- to small-part manufacturing and produce more accurate parts with tighter tolerances.

Share

While riding the ebb and flow of larger-part manufacturing for military contractors, Ron Markoff, president of Progressive Tool, began to notice a trend of parts becoming smaller and lighter. To ensure survival and success, Mr. Markoff decided to change Progressive’s direction and gradually replace its machines with those geared for smaller, more precise work. To complete this shift, Progressive integrated GibbsCAM software from Gibbs and Associates (Moorpark, California). Now, the shop is able to supply a different niche of military parts that are smaller in size and weight.

The Binghamton, New York, shop was founded in 1956. For decades, most of the shop’s work consisted of removing massive amounts of material to reduce weight in larger parts and creating pockets to house electronic components. However, in the early 2000s, RFQs for these traditional parts began to fade. New composites were making lighter parts possible through lay-up and vacuum forming, and other parts were getting smaller through miniaturization of electronic and electro-mechanical assemblies, which could use much smaller enclosures. It licensed a new CAM system in 2004, but it ultimately failed due to lack of support and bug fixes, among other issues. After a two-year struggle with the software, Progressive cut its losses and licensed GibbsCAM software.

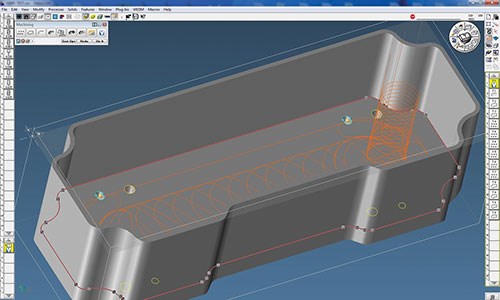

Programming the machines is now quick and simple, says Pat Crowley, plant manager. Unlike the previous system, GibbsCAM is able to open CAD models, including solids as well as IGES and STEP files from CATIA and PTC/Creo customers. The software can be used on a variety of machines, including the company’s wire EDM, lathes, five-axis machining centers and multitasking machines.

Mr. Markoff and Mr. Crowley quote jobs together as they review parts with GibbsCAM. In fact, effective visualization and quick and easy programming enable Mr. Crowley to do some programming while quoting. The machining process he creates becomes part of the NC programming when the shop gets the job. “With small parts, the time to machine small and hidden features becomes important, especially with tiny tools, deep grooves and sharp pocket corners,” he says. By programming some of those features ahead of time, the company knows what it takes to machine the part, and its quotes are more accurate. Plus, some critical work gets done ahead of the job.

Using the new machines and GibbsCAM, the company was able to transition from the common 24-by-24-by-4-inch work of previous years to 2-by-2-by-0.500-inch work. As tiny features and undercuts in drawings became more difficult to discern, reliance on solid CAD models and GibbsCAM increased. Mr. Crowley explains that GibbsCAM enables machinists and programmers to inspect customer models and add or subtract features for machining. Often, he found that making tooling and fixtures as he programmed parts didn’t take much work because the software picked up geometry from part features. “I can model anything I need, right there. We don’t need any other CAD,” he says.

The CAM software’s associativity became more important as it transitioned to small parts with many pockets and tiny features. For instance, Mr. Crowley can select CAD model geometry and link part features to tools, operations and layers. “The ability to isolate and associate features by operations or sequences saves a lot of time,” he says. “If you call up a tool or layer, everything linked to it shows up.”

Another important benefit of the new CAM software is ease of use, says 16-year machining veteran and first-time CAM user, Brian Fish. Production demands on his job as CNC lathe supervisor, machinist and lathe programmer, left him no time to learn GibbsCAM on his own, but he learned the software quickly with occasional in-house training sessions. “I would call our GibbsCAM reseller when I had questions, but otherwise, I just turned on the software’s help feature,” he says. “I could get on-screen explanations for menu buttons. It was very straightforward and useful.”

As Mr. Fish programmed two-axis lathes, he began doing things the shop had never done on those machines and reduced the number of operations required to make several parts. After similar success on a high-volume part for an electric bus, he started to consider how more capable machines might provide further efficiencies on that job. This led Progressive to acquire its first multitasking machine, an eight-axis Nakamura Tome WT-300, just to make that part.

Moving from two-axis machining to eight was difficult because he had no experience with multitasking machines. Yet, using GibbsCAM, Mr. Fish was able to reduce five operations on two lathes to a single operation—with total operations reduced from eight to three. Time also improved from 3 minutes for each of the previous five operations to 5 minutes for the single operation. Reduced handling and setups ultimately improved part quality.

A year ago, Progressive also acquired its first five-axis machine, a Brother TC-S2C-0 with Nikken rotary-tilt table. To program it, the shop added the GibbsCAM five-axis module, which Mr. Crowley was able to learn on his own. “We don’t do much five-axis work, so I don’t use it often, but it wasn’t difficult to learn,” he says. “There’s always a way to find the information you need, right in the software.”

Using GibbsCAM and its new machines, Progressive Tool now makes small parts with tighter tolerances than previously required. It supplies small military parts, including those for satellites and night-vision goggles, made from titanium, stainless steel, aluminum alloys and various Kovar alloys. Work has changed from hogging out 2-foot-long parts to parts as small as 0.500 by 0.500 by 1 inch. The relative percentage of material removed is about the same, but the tools, speeds and feeds are tiny by comparison. “We might be hogging out a pocket with a 0.125-inch tool, or cutting a 0.31-inch-wide, 0.5-inch-deep slot with a 0.025-inch cutter, and GibbsCAM helps us drive them without breakage,” Mr. Crowley says. “It lets us machine any way we want, with any toolpath pattern. We know most of the alloys really well, so we enter speeds and feeds on the fly, but when we use a less-common alloy, the software’s default values are right on the mark,” he says.

As with large parts, toolpath efficiency makes a difference in the profitability of a production run, but tool life for fragile tools is even more important. For both reasons, Progressive recently added VoluMill for GibbsCAM. This software optimizes tool paths for fast material removal while compensating for changes in cutting direction. This ensures a constant load on the cutting tool, or constant chip thickness, to minimize tool deflection and extend tool life. “After you select pockets and your cutting tool, a single mouse click is the only interaction you need to activate VoluMill for your tool path,” Mr. Crowley says. GibbsCAM VoluMill cuts 15 to 20 percent off cycle times for the company’s small parts.

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)