Share

Autodesk, Inc.

Featured Content

View More

Beryllium stock is about 10 times as expensive as aluminum, McKay says. To avoid scrap, the company makes test parts out of aluminum to prove out machining processes and programs before embarking on a beryllium version.

Beryllium may be lighter than aluminum, but it’s also a toxic, costly metal that requires machine shops to prioritize quality above speed. Specializing in this metal presents unique difficulties when optimizing machine productivity, as automation and advanced toolpath strategies successful for other metals are often impractical. But the beryllium specialists at San Jose, California-based job shop WessDel have boosted both the shop’s productivity and revenue by leveraging the data visibility it gains through Harmoni, an adaptable shopfloor data system that merges elements of multiple shopfloor management technologies into a robust whole.

Growing a Beryllium Job Shop

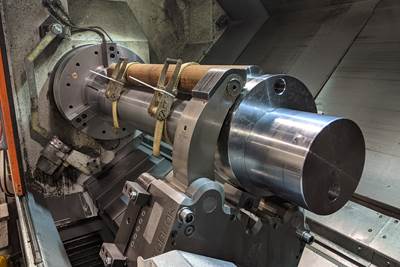

WessDel was founded in 1978 and had just started dipping its toes into beryllium parts when its current management bought the company in 2002 and tripled down on this niche. Today, the shop primarily works on aerospace and defense parts, especially satellite structures and components. It is one of the few job shops in the country equipped to work with beryllium and AlBeMet (an aluminum-beryllium alloy), and every machine working on these materials works in negative pressure with a vacuum connection to a HEPA filter at the back of the shop. Many of these machines are three-axis vertical machining centers, though WessDel does also use two five-axis machines, two four-axis horizontal mills and an EDM machine in addition to a waterjet machine, some manual machines and a small lathe department.

WessDel President and CEO Bob Dorricott says that the shop’s high number of VMCs stems from their compatibility with quick-change workholding, which he finds far more useful than automation capability due to the shop’s low part volumes, exceptionally tight tolerances and high material costs. For context, WessDel Vice President Jeff McKay says beryllium stock can be 10 times more expensive than aluminum, pointing to a yoke hub that cost over $100,000 in material alone. Beryllium is also highly abrasive, requiring different speeds and feeds than aluminum and wearing out tools within three pieces in most cases. Pure beryllium also has the disadvantage of being fracture-sensitive, requiring diminishing cuts to minimize microfractures in the part surface. This minimization is especially important, as the shop’s critical tolerances are often in the ten-thousandths of an inch.

These factors make automation and experiments with speeds and feeds prohibitively risky, ruling out some of the most common methods of increasing job productivity. So when WessDel set out in 2022 to double its previous year’s revenue, the shop needed to determine alternative ways to increase productivity. First among management’s ideas was to reduce the time WessDel staff spent on non-machining tasks. At the time, staff members needed to manually clock in and out and track time spent on each job using one of three shared kiosks on the shop floor. Not only was this data prone to estimations and errors, but it often resulted in lines at the kiosks as staff members waited for their turn. The WessDel team calculated that each trip to the time clocks would take just over 10 minutes on average. What’s more, this data entry took place five times a day, so the shop would lose 50 minutes of productivity every day — or about 10% of the productivity from a shift.

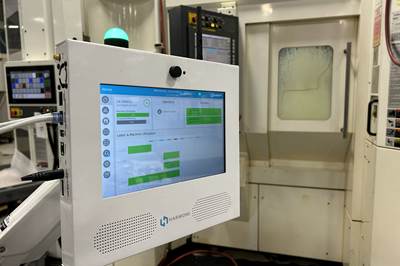

McKay turned to several time clock providers for assistance, and one eventually recommended that WessDel look at Harmoni, which includes a time clock function as part of its overall package. The Harmoni system uses RFID technology to automatically clock users in and out of jobs directly from the terminals attached to machine tools, while also automatically tracking time spent on these jobs. This eliminated WessDel’s long-running timekeeping accuracy issues while also reclaiming 50 minutes of productivity from every shift. The shop quickly calculated that these savings would result in tens of thousands of dollars of increased revenue each month — paying for the Harmoni system by a factor of five.

The granular level of reporting and revision control onboard the Harmoni system make determining the source of errors relatively simple. WessDel’s team can compare program updates to error incidences, and so swiftly determine which changes to revert.

More Than Machine Monitoring

Though this feature alone made Harmoni useful to WessDel, Harmoni Co-Founder Adam Ellis says it is only a small part of the system. He says that what usually captures shops’ attention is the system’s ability to integrate with many ERP systems out of the box, monitor machines and improve data visibility into key shop profitability metrics like quality and OEE. And despite being a high-mix, low-volume job shop with little ability to leverage traditional statistical process control, WessDel also found these other aspects of Harmoni incredibly useful.

As part of its machine monitoring abilities, Harmoni includes an indicator light both on the physical device and in the software to mark each machine’s efficiency in real time — green for on track, yellow for falling behind and red for well behind the estimated time to complete the running job. Despite some initial misgivings from staff, the challenge of keeping the lights green swiftly brought out the competitiveness of WessDel’s machinists. When machinists find the estimated time for completing a part to be unfeasible, they now approach the engineering department and collaborate to develop more accurate time estimates.

WessDel has been able to further clarify its data by working with Harmoni to refine the lighting system. For example, the two companies developed a toggle to give partial credit for work that requires production times over a full shift — work that would otherwise continually show as falling behind schedule due to a lack of complete parts until the very end of the work cycle. Harmoni also updated the lights to show blue during setup, helping WessDel distinguish between setup and other forms of downtime.

The data Harmoni captures about machining activity and performance feeds into dashboards that WessDel can break down by job, part, machine and employee. While small part quantities and large gaps between repeat orders make traditional job-focused continuous improvement efforts unfeasible, the patterns the various dashboard views reveal help WessDel determine where problems regularly start and how to fix them. If jobs routinely run long on a machine, perhaps WessDel needs to adjust the estimates for jobs running on it. If jobs only run long under a specific employee, perhaps WessDel needs to work with that employee on filling a training gap. Solving these issues helps the company improve the accuracy of its quotes — and more accurately forecast its needs.

Consistent Processes, Controlled Revisions

While quotes go a long way to winning work profitably, WessDel has also been able to use Harmoni to fulfill traceability requirements. McKay describes Harmoni as a full MES system in this context, as it handles revision control and distribution of programs, work instructions and check sheets.

With program loading, “You’re taking human error out of the equation,” McKay says. The system automatically tracks up-to-date versions of part programs, including any necessary per-machine variations, and sends these to the machines. It loads the part programs by emulating a USB drive — albeit one that only includes the correct program. Harmoni Co-Founder David Caputo says that this not only eliminates the potential for outdated programs to be drifting around the shop floor, it also helps shops meet stringent process control certification requirements. The program management capabilities are also bidirectional, with any changes an operator makes on the shop floor pinging back to the engineering team for approval. What’s more, when engineering accepts these changes (or makes any others), users who log in to that job then get an alert to inform them of the changes to the program. This goes a long way toward ensuring standardization, as machinists can’t simply fall back into what they remembered doing the previous day.

WessDel has also standardized processes by using Harmoni’s “work instructions” feature. This feature uses the screen on the Harmoni device to provide visual aides about fixturing, clamping spots and other setup necessities. McKay says that this immediately proved useful, as during staff training on the system multiple machinists mentioned that they had been following their own, different setup strategies for years. The team determined which of these strategies to include in the work instructions, and now all machinists know how parts are meant to be set up and which tools to use at each machining step, improving traceability and consistency.

Harmoni can track jobs and machinists across the shop floor using RFID tags, pulling up the programs which correspond to nearby jobs. The system also includes a multi-factor authentication system where certain jobs can be “locked down.” This means that only people with the proper clearance or training can clock in to those jobs or access sensitive data such as their programs and work instructions.

Quality Part After Quality Part

Harmoni also includes digital check sheets, which enable WessDel’s machinists to track their parts’ critical dimensions before they go to quality control. This can save time as machinists catch out of spec parts early before potential issues propagate through entire batches of parts. This reduces scrap while freeing the quality department to focus on parts’ difficult dimensions.

As with the tooling in the work instructions, the check sheets indicate which inspection tooling to use at the current stage in the process. WessDel’s inspection tooling includes Bluetooth-enabled calipers and other Bluetooth-enabled inspection devices. This marks another area where Harmoni can eliminate paper from the shop floor, as these devices deliver information directly to the system, which automatically builds a spreadsheet that indicates in real time whether a part is in tolerance across its dimensions.

Pushing Shop Limits

The shop’s repeatability and improved consistency in meeting tight tolerances has caught the eye of some of its frequent clients, and McKay says that one OEM recently offered WessDel the opportunity to enter a mentor-protégé program that could see the shop upskilling to meet tolerances down to millionths of an inch.

But even beyond opening new doors, McKay says the data visibility and accuracy within Harmoni have been vital to planning for the shop’s future. By cross-checking OEE with future work in its backlog, WessDel has been able to determine which machine groups would be overtaxed in its near future and use this information to guide purchasing decisions. Already, the shop has added two vertical Haas mills to ensure it can continue meeting its lead times.

“It really comes down to the data accuracy,” McKay says. “At the end of the day, that’s what we need to make good decisions.” From time clocks to program revisions to quality, the shop says it has found what it needed, and it is on its way to meeting its revenue goals.

Related Content

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreContinuous Improvement Requires Continuous Effort

So-called “busywork” hones natural instincts for reform as a specialist CNC machine shop adapts a more formalized methodology.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)