Top Shops Profile: C&M Machining

C&M Machining was the 2016 Top Shops Honors Program winner in the category of business strategies.

Share

C&M Machining is 2016’s Top Shops Honors Program winner in the business strategies category, given attributes such as its high profit margin, growth rate and quote-to-book ratio compared to other shops.

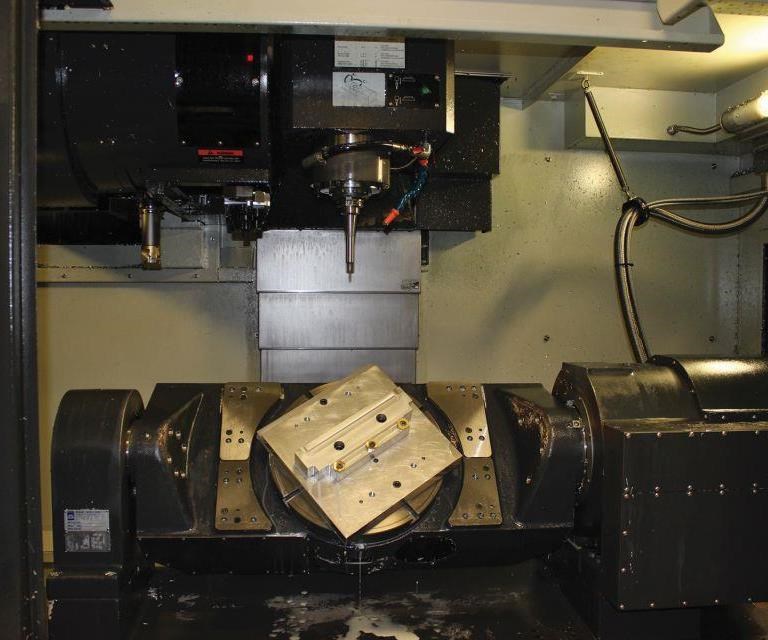

The 100 percent woman-owned shop was founded in 2005 by Cheryl K. Miller with a vision of becoming a leading CNC precision machine shop providing competitively priced, accurately machined components to the aerospace industry. In fact, 99 percent of the company’s sales comes from the aerospace industry in job orders ranging from single prototypes to millions of parts. C&M Machining is an AS9100-certified manufacturing company specializing in interior and structural components and assemblies for aerospace, defense and outer space applications.

End Markets Served

- Aerospace

- Defense

Workpiece Materials Commonly Machined

- Aluminum alloys

- Brass

- Bronze

- Plastics

- Tool steel

- Steel alloys

- Titanium

Related Content

-

Creating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

-

Top Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

-

Top Shops 2024 Is Now Live

The Top Shops 2024 survey for the metalworking market is now live, alongside a new homepage collecting the stories of past Honorees.

Related Content

Creating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreTop Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreTop Shops 2024 Is Now Live

The Top Shops 2024 survey for the metalworking market is now live, alongside a new homepage collecting the stories of past Honorees.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More