Positioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

Share

At Stecker Machine Company, operators regularly use gauges to measure features for every part that comes off the machine. The company places such a high importance on quality checks in order to guarantee quality for customers.

According to Stecker Machine Company, the Wisconsin-based Top Shops honoree in the category of Shopfloor Practices, a shop’s workflow should be designed around the needs of the machine operators. “We like to put people in situations where they can prevail instead of fail,” says Bay 1 Production Supervisor Dan Luckow.

For Stecker, this has led to a workflow in which support staff do their best to keep production running smoothly, and technology is used to eliminate human error as operators focus on getting parts through their machines.

A Seamless Workflow

Stecker is a large shop with over 80 machining centers and over a dozen lathes spread out between two facilities. A family-owned machine shop, it seems nearly every one of the over-250 employees has family who work there, too. The vast majority of the shop’s work is machining features into complex iron and aluminum castings. While some cells are automated, the vast majority are attended by operators, and they have developed robust strategies for keeping parts moving through the line.

Toolroom personnel prepare each shift’s tooling needs before the shift begins, making sure each job has a tool cart loaded with exactly what it will need by the time the operator needs it. When the operators arrive for work, they simply take the carts they'll be using for that day and wheel them to the proper workspace.

The toolroom prepares tooling for every job ahead of time before placing it on a cart for the operator to retrieve. By eliminating this and other tasks from the operators’ workload, Stecker enables them to concentrate on running the machines, deburring parts and checking quality.

To avoid interrupting production, the company prepares the tooling for dozens of machines and three shifts every day. This means keeping two fully staffed tooling teams, one for each facility. However, this investment in time and resources is worth it to the company, which prefers to limit the workload of its operators to keep them focused on getting good parts out of the machine.

The operators range in experience from green workers at their first job to journeyman machinists with decades of experience. While more experienced machinists will take on more complicated projects, every operator loads and unloads parts, monitors machining operations, deburrs and validates part features using gauges.

By putting so much effort into preparing the operators’ tooling before they even arrive, Stecker makes it easier for both newer and experienced machinists to consistently produce parts from complex castings in batches of dozens or hundreds. This approach minimizes disruptions and makes even less experienced operators productive.

In Bay 1, most finished parts are placed on a conveyor system that takes the part down to the washing line. There, the attending workers clean and inspect the parts before packaging them for shipping. This is one example of how Stecker uses multiple teams to keep parts moving through the facility.

And this approach goes further than just tooling. Because the company is focused on letting its operators perform the work that has to be done at the machine, it has moved much of the rest of the work to other departments. The maintenance department, for example, keeps coolant replenished. Finished parts are placed on a central conveyor belt in Bay 1 so dedicated workers can clean and package them. At every point, the company has asked, “How can we get parts through faster?” and has discovered that rather than putting more and more work on their operators, production moves more smoothly when every department is working in concert to get parts moving.

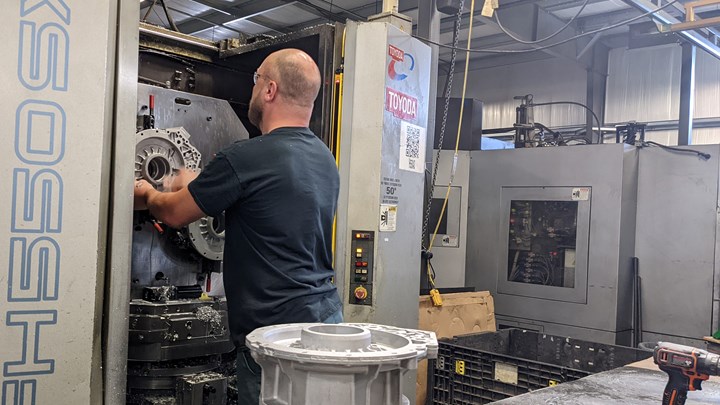

A Stecker operator places a casting into the work envelope of this Toyoda, one of 69 horizontal machining centers in the shop.

Operators are also assisted by the Plex ERP system, which provides them with instructions for each job and guidance for validating part measurements, including pictures that illustrate which features to measure. These instructions make it as straightforward as possible to inspect parts, and this verification process takes up a major part of the company’s rigorous training program for new employees.

Continuous Learning

That training program that has achieved impressive results in terms of preparing employees to succeed and to advance. Nearly every position, including most managers and engineers, is filled by someone who began as an operator on one of the company’s machine tools. Most of them were trained by Stecker, which means nearly every employee understands the machining process.

Take Process Engineer and Employee Development Manager Jake Schermetzler, whose current job is to create process instructions for deburring. According to him, spending time as an operator was of tremendous value. “I have a fuller understanding of the operators’ perspective, and that means I can give people better instructions.”

Employee Development Manager Taylor Madden is in charge of training operators at Stecker. “Everyone is taught the same down to how to operate gauges,” he says. “So everyone is operating with the same mentality.”

“We’re trying to produce operators who want to advance in machining,” says Employee Development Manager Taylor Madden. This means that training does not end with the training program, and managers keep an eye out for talent. “If we see you demonstrate an aptitude for machining, we’ll partner you with an operator doing more complex work.” And Madden is out on the floor answering questions and providing help whenever needed.

“If everyone is looking at quality at every stage, you get good parts.” -Taylor Madden, Employee Dev. Manager

The training program itself spends some time on the fundamentals of machining, but it emphasizes time spent at machines. “The idea is for classroom work to be sufficient to understand what’s expected on the shop floor,” Madden explains. “Once that is achieved, they will learn more from time paired with more experienced operators than they will in the classroom.”

Training also emphasizes the use of gauges to measure part features, as well as how to identify chatter and other imperfections. Most operators at Stecker validate every part that comes off the machine unless process limitations make doing so unfeasible. From there, “Every day, the first part to come off each machine goes back to the CMM room,” Madden says. “Every operator inspects either every part or a regular sampling of parts to ensure quality. If everyone is looking at quality at every stage, you get good parts.”

Consistency is Key

A key goal of the Stecker production line is to reduce the possibility of human error as much as possible. This means eliminating risks before machining starts. One example is in the shop’s use of high-end toolholding such as a quality shrink-fit system. “Complex castings tend not to be very rigid,” says Stecker Co-President Brad Kurtzweil. “So we add rigidity to the tooling and workholding.”

Here we see some freshly plumbed hydraulic workholding plates. Stecker exclusively uses hydraulic workholding to ensure repeatability and consistency.

The workholding is almost all hydraulic, designed and built in-house. Hydraulic workholding and shrink-fit toolholders might seem like overkill in a shop that primarily works on iron and aluminum castings, but the goal is to reduce the number of ways parts can develop flaws or inconsistencies. “With hydraulics, we get rigid holding, and we reduce human error,” says Improvement Engineer Dan Karbon. “Other clamping methods work fine, but we can count on hydraulics to always provide the same level of force.”

Coninuous Improvement

Karbon is in charge of developing tooling for new jobs, so he has his hands in just about every job that makes its way through Stecker. “I get to work with everybody from the guy who signs my paycheck to the guy who sweeps the floor,” says Karbon, who like many employees has family working at the plant alongside him.

In addition to preparing tooling strategies for every new job, Karbon is in charge of the company’s continuous improvement strategy. “If a job is not making rate, we do time studies,” he says. If time studies confirm that the job is not making rate, they put cameras in and around the machine to figure out what is slowing down the process.

Sometimes, Stecker combines manufacturing cells to get the best work out of them. This cell contains two mills and a lathe and is operated by two employees. Together, these three machines and two operators can produce complex parts more quickly than they could apart.

“Sometimes, for example, benchwork is slowing down the process, so we move deburring to the machine and get better time despite the longer cycle,” Karbon says. Key to this process is trust. “I always take the side of the operator. You have to have a rapport with them. You can’t come at it blaming them from the start.”

Stecker has found that a company can show its employees they are valued by behaving as though they are valuable. At every stage of production, management operates from the position that it should be helping its employees succeed.

Related Content

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More