How a Mom-and-Pop Becomes a Top Shop

Process and culture shift as leaders adopt new business strategies and a singular focus on expanding and filling capacity.

Share

Steve Tury of ACR Machine Co. has a simple goal: “I want to see tractor trailers going out of here every day loaded with product,” he says. “That’s the best feeling in the world.”

More five-axis machining centers like this relatively new model are a target of future investments at ACR, a job shop where quantities are low and few parts are alike.

Until recently, Tury says he hadn’t felt that way for a long time, but not because the business had been unsuccessful overall. It’s just that success was defined differently. Making a profit was enough; the pace was slower. With the early 2020 retirement of Tury’s business partner — the man from whom he first bought an ownership stake in the Coatesville, Pennsylvania, job shop decades ago — selling the company seemed like the right move.

Instead, Tury decided to go another way. ACR posted a nearly 70 percent increase in year-over-year sales, and Tury is anticipating the need for more of those tractor trailers.

Of all the changes at the root of this achievement, he says the most significant is philosophical: a renewed drive to not just make a living, but also to grow the business. The primary means to that end — what makes ACR Machine Co. stand out as the 2021 Top Shops Business Strategies and Performance honoree — are the organization-wide alignment of process, technology and people toward common goals and the leadership’s dedication to managing this job shop like the larger company it aims to become.

“We grow through cash flow, not through debt.” – Tony Wilson, ACR Machine Co.

Strong Foundations

Tury has spent much of his career focused on sales for the shop: finding new work and retaining existing customers. Selling the shop itself might have been a natural next step were it not for his retiring partner’s brother-in-law, Tony Wilson, a former corporate executive who had been asked to evaluate the company first.

With experience running multiple large manufacturing plants, Wilson soon found himself moving from dispensing advice to discussing the possibility of a new partnership. “This was a really good business model,” Wilson says. “Believe me, I’d rather be playing golf than banging my head against the wall every day.”

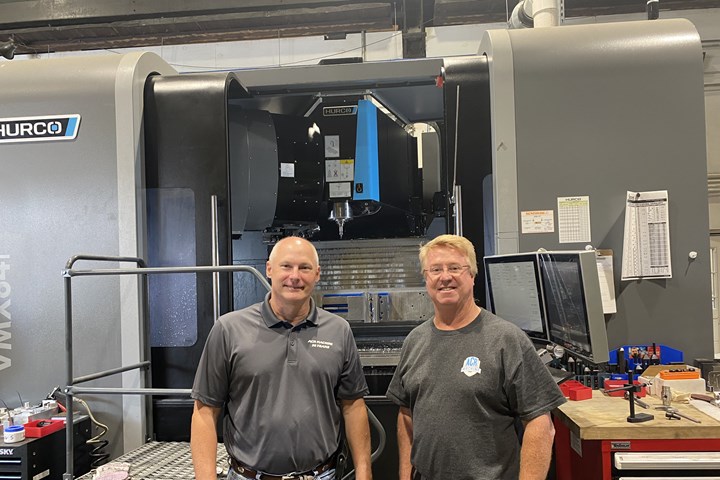

Steve Tury (left) and Tony Wilson set ambitious goals for growth at the Coatesville, Pennsylvania, job shop.

Cash on-hand and a strong backlog provided solid foundation for growth, Wilson recalls. He also saw great promise in the exclusivity of the work at the 25,000-square-foot facility. Large parts are a particular specialty, and more than 80 percent of jobs specify tolerances of at least 0.001 inch. ACR also struck Wilson as being highly certified for its size. It has both ISO9001 and AS9100 quality control certifications, as well Federal Aviation Administration (FAA) qualifications for repairing aircraft components (he adds that the shop has since also earned the equivalent European Union Aviation Safety Agency (EASA) qualifications, and it is well on its way to earning ISO 13845 for internal prosthetics). As a result, ACR had already solidified a strong niche in the aerospace, defense and medical sectors when he conducted his initial evaluation.

Quality control has been a primary focus of investments in quality control technology, such as this Keyence visual inspection system, and in people, with staff growing from one to four inspectors.

Tury also proved to be a kindred spirit with similar patterns of thinking – one who also recognized the need for change at ACR. Meanwhile, Wilson’s growing excitement about the business provided Tury with outside validation that the work and risk associated with expansion would be worthwhile. Business had been steady for most of the past few decades, but “we had gotten complacent,” Tury says.

Cash Comes Back

Among the first and most fundamental changes was the decision to reinvest all profits back into the business. “We grow through cash flow, not through debt,” Wilson says. “The focus is on booking and on shipping parts, and we never take cash out of the business.”

Very large parts – particularly those like this circular component for a Navy aircraft carrier assembly, which also requires managing schedules for multiple outside processes – are a particular specialty for ACR Machine Co.

This strategy requires the kind of financial planning that is more like what Wilson experienced at larger companies. Formal plans for capital expenditures and other investments extend three years into the future, with short-term goalposts to mark progress toward longer-term aims. Overall, the aim is to gross $15 million per year. Having already climbed from $5 million to $9 million last year, the shop is well on its way.

Relying on cash flow requires carefully prioritizing investments. “More horizontal mills, five-axis expansion, Swiss-type lathes, mill-turns, laser welding, facility space – all of this can be conflicting,” Wilson says about investments yet to come.

Careful prioritization is obvious on the shop floor, where the gleaming metal of brand new Hurco VMCs stands out against the few remaining Fadals. However, the older machines are just as capable as they were on the day they were purchased, Tury says, largely because the staff can maintain them in-house with readily available spare parts. Meanwhile, the process around the machines has benefitted from six-figure spending on various information technology needs, including a new server, cybersecurity training, an additional programmer, the construction of a separate programming office, and the addition of enterprise resource planning (ERP) software.

Cleaning and organizing the shop floor were among the first orders of business before adding new machine tools.

Processes Shift

Sound financial management has been complemented by a focus on reducing waste and costs wherever possible. Renegotiated utility contracts prove that fixed costs need not be fixed, and changing tooling vendors has saved 40 percent on tool costs. The ERP software, Shoptech’s E2 system, has significantly simplified tasks associated with managing the business.

To save money and time on managing coolant, ACR uses a homegrown, centralized storage system that pipes the fluid to individual valves at each machine tool.

On the shop floor, process changes include various 5S and Kaizen projects, new quick-change fixtures and the addition of a distributed numerical control (DNC) system for standardizing the distribution and management of CAM programs. Daily Gemba walks – a practice carried over from Wilson’s previous work — help ensure that previously unquestioned habits are challenged regularly. One recent example is the seemingly intuitive practice of producing excess parts for a repeat order before tearing down the setup. “People weren’t always considering the real impact on the cost of materials, on the cost of labor and, most of all, on the impact on other orders,” Wilson says.

Rather than the old punchcard system, operators now log into ERP software at shopfloor terminals.

Technology and process changes aside, Tury and Wilson say investments in people have made the biggest difference in ACR’s rapid, recent growth. Most notably, expanding the staff from 15 to 35 – largely via the ZipRecruiter service, which Tury and Wilson praise for providing a steady stream of pre-vetted candidates – has enabled the addition of a second shift. The first shift’s 17 employees now focus primarily on preparing four second-shift operators to run the machines with as few interruptions as possible.

The front-office also includes two new, high-level hires: Doug Daly, business development manager, and sales manager Bob Tury, Steve Tury’s brother. Their job is to keep the company on a growth path by ensuring it books more work than it ships. To that end, weekly demand generation meetings help formulate strategies for “segmenting” prospective customers, obtaining supplier approvals, finding the right contacts and building relationships. E2 has been a massive help, Bob Tury says. “We have great visibility into metrics and a reporting capability that just wasn’t there before. I’m always revisiting it to try to understand why we lost a quote.”

The Team Buys In

The right tools, and even people with the right skills, go only so far in executing any business strategy, whether on the shop floor or in the front office. At ACR, the new way has required instituting accountability where none existed before. Now that the shop is setting goals and tracking metrics and using new tools like E2, “everything is transparent,” Steve Tury says. Amid changes like adding a second shift, the nature of the work transformed radically away from the long-term status quo, and the culture began to change. Some veterans left.

Having a solid business plan is an essential first step to getting team members to think beyond a paycheck and achieve unity of purpose.

As for the rest of the crew, Tury and Wilson say focusing heavily on communication and engagement has helped alleviate the natural friction of change. For instance, one area of specific focus is what Wilson calls circular communication, which fosters team building. “You can communicate to anyone across the center of the circle,” he says, explaining that the idea is to avoid the negative conditioning that comes with instincts to go “up the chain” with any problems. “Assigning blame and holding people accountable are very different things.”

Wilson and Tury strive to provide everyone with all they need to do their jobs effectively. Programmers like these (one of which is a new hire) need space to think and collaborate, hence the construction of a new office.

This approach proved critical when navigating the roughly year-long transition to adopting a second shift. As for engagement, Wilson says having a solid business plan – as he puts it, providing “the resources, a business structure and a sound financial plan that enables [employees] to do their jobs” – is an essential first step to getting team members to think beyond a paycheck and achieve unity of purpose. For Wilson and Tury, that means being as transparent as possible and setting the right example, such as working longer hours when necessary. “When they understand the importance of the job they’re doing while they’re here — not only to the business, but to each other and to the customer — people will hold themselves accountable,” Tury says.

Finally, they emphasize that organization-wide harmony begins with their own relationship. Prior to formally going into business, each listed personal, professional and spiritual goals in three columns, then they compared lists, agreeing that any significant misalignments would end the burgeoning partnership there. “We spend more of our waking hours together than we spend with our wives,” Wilson says. “It’s important that we get along.”

Exit Strategy

However, the partners’ time working together was already coming to an end by the time Wilson made those statements about interpersonal harmony. Shortly after this article was written, a group of outside investors who own other nearby machine shops offered to buy ACR. The timing may have been unexpected, but the offer was not, Wilson says, noting that an exit strategy is critical for any business plan.

ACR is changing fast. Troy Reaser, the company’s new president, stepped into a leadership role shortly after this article was written.

He has since returned to retirement. Tury, meanwhile, opted to stay in the business, which is now led by a new company president, Troy Reaser.

Reaser says he and his partners, who own multiple machine shops, saw opportunities to diversify by leveraging the same strengths that Wilson had identified in ACR less than two years prior. Of course, the shop’s recent, rapid growth played a key role as well. “Just a few years ago, when (ACR’s) business was just steady, I don’t know that the company would have been as attractive,” Reaser says, adding that he is eager to continue what Wilson and Tury started.

Related Content

-

2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

-

Benchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

-

Complete the 2024 MMS Top Shops Survey

Related Content

2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreJob Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreRead Next

Automation Adds Capacity to Capability for Low-Volume Work

Investment in machining technology has facilitated growth and diversification at Reich Tool & Design. Now, flexible automation allows the shop to get more out of its machines despite a shortage of skilled workers.

Read MorePutting People First: a Profitable Strategy

Treating people fairly and valuing their contributions isn't only the right thing to do. It’s also a direct path toward greater profitability, as shown by this Top Shop.

Read MoreThe Art of Maintaining Continuous Improvement

Production efficiencies, setup efficiencies, plant utilization record, safety records, on-time delivery performance — all of these metrics and more place Forest City Gear among the elite when it comes the use of ongoing improvement methodologies.

Read More