Share

When your machine shop has manufactured parts for Boeing, Airbus, Rolls Royce, NASA space shuttles, and the International Space Station, and when it has machined gears that have been used on four Martian rover vehicles and a fleet of Abrams tanks, clearly you are doing many things right. In the case of Forest City Gear (FCG) — a manufacturer of fine- and medium- pitch custom gears — success can be attributed largely to three overarching commitments: Ongoing employee training, annual investments in new technology, and a meticulous set of shopfloor processes and practices that place the company in an elite tier of contract manufacturers.

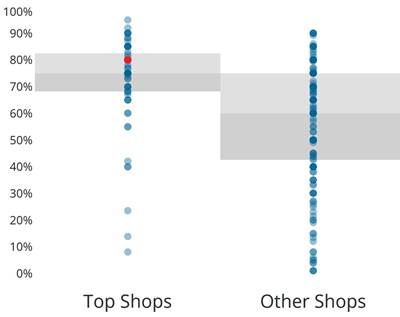

Forest City Gear’s rigorously maintained shopfloor processes and practices have also earned the company its title as a 2021 Top Shops winner, a status underscored by an on-time delivery rate of 98% for parts that are often highly complex.

What surprised me during a visit to FCG this summer, however, was that for a company that makes considerable investments in new technology — up to 40% of its gross sales each year are designated toward purchasing the latest CNC gear hobbers and new CNC turning and milling machines — some of Forest City Gear’s most impactful shopfloor practices involve a series of simple paper printouts and inconspicuous setup stations.

That fact the company’s scheduling boards (or “war boards”) and its machine-specific setup kits are so critical to its success might not be a conclusion one would draw after a quick scan of FCG’s shopfloor. But a closer look paints a different story.

An example of the full range of “cut-teeth-only” size capabilities at Forest City Gear, which extend from 0.100 to 24 inches.

The Breakthrough Idea

Forest City Gear is a second-generation, family-owned shop led by Fred and Wendy Young, the former of whom took over the business after his parents retired in the early 1970s. Wendy Young, who serves as president, leads day-to-day operations of the company today. FCG employs roughly 120 people who work in two adjacent buildings in Roscoe, Illinois, a suburban area located on the norther edge of Rockford, (a.k.a., the “Forest City”). The two employees I spoke with during my visit, CNC department lead Josh Gates and division manager Mike Miller, estimate that roughly 60% of FCG’s parts are for the aerospace industry, with the remainder dedicated primarily to the medical and defense industries.

Today the company produces more than 70,000 gears per month in a variety of steels, aluminum, brass, bronze, Inconel, titanium, Hastelloy, and several other materials. Complicating matters further? These 70,000 gears are split into two distinct production chains: “Cut teeth only” and “make complete.”

On one hand, the names of these two types of work are self-evident. Cut-teeth-only orders can arrive unexpectedly, and turnaround is expected to be quick because FCG is only cutting gears into blanks and sending the incomplete part back to the customer. Make-complete orders, meanwhile, require full production runs.

The customer’s part print order goes to the engineering department, which conducts a contract review and maps out the operations the part will require, from heat treatments to finish machining. The lead times for make-complete parts are necessarily much longer than cut-teeth-only work due to the magnitude of work required to make highly complex gears from start to finish.

For many years, Forest City Gear tried to manage these very different types of work using the same shopfloor resources, regardless of the fact that one type of job was mapped out meticulously and the other would show up unexpectedly and require a fast turnaround. The result was that machines designated for make-complete parts would suddenly be put to use for cut-teeth-only parts, creating bottlenecks and unnecessary chaos on the shop floor.

Then came a breakthrough idea that resulted in a much more manageable process — an idea derived squarely through FCG’s adherence to continuous improvement.

Forest City Gear produces more than 70,000 gears per month in two distinct production chains: “Cut teeth only” and “make complete.”

The Four-Idea Rule

“‘Continuous improvement’ is as old as man.’” These are the words of Fred Young, chairman and former president of FCG, who wrote about his company for Modern Machine Shop nearly 15 years ago. “It takes more than good price, quality and delivery to distinguish a manufacturer these days.” In practical terms, this adherence to what Young calls “excellence without exception,” the company’s motto, resulted in one protocol that remains in place at FCG today: All FCG employees are required to submit four ideas per year for improving efficiency or overall workflow on the shop floor.

The idea that helped solve the company’s intra-competition for shopfloor resources was this: Separate the production paths for cut-teeth-only work from make-complete work by earmarking the most suitable equipment for one process or the other. Newer or more automated equipment was assigned to cut-teeth-only work, since those customers often required fast turnarounds for jobs that other shops couldn’t perform, such as machining a unique profile or crowns for gear teeth.

Delivery times for cut-teeth-only work went from three-to-six weeks down to two or three weeks — an immediate 25% improvement for work that constituted roughly half of FCG’s gross revenue.

Not all of the continuous improvement ideas are this ambitious, of course.

Miller is part of the continuing improvement team at FCG that meets once a month to review submitted ideas. These run the gamut from organizational restructuring to a machine operator suggesting that his workstation could use a new wrench. And yes, even this modest idea turned out to be an important one.

“We accept all ideas,” Miller says. “That doesn't mean we can implement them right then and there, but sometimes a small idea spurs another and creates a conversation.” Which is exactly what happened with the modest suggestion for a new wrench.

A machinist at Forest City Gear cleans up his workstation and setup kit. These kits were recently installed at each machine as part of FCG’s dedication to continuous improvement.

Learning Is What We Do

In fact, the request for simple tooling items at each machine spurred a reduction in Haverage setup time for machining operations from 3.5 hours to 2. It turns out that one of the biggest drags on setup time, Miller and Gates found, occurs when tooling is missing from a machine. Missing tooling requires an operator to leave his or her station to track down the needed items, whether it’s an arbor, a cutting tool or a wrench.

So what did they do? “Well, we're creating kits at every machine,” Miller says. “We created tool boards at every machine with all the tooling that everyone needs.” These tooling kits are machine-specific and include a Lista cabinet filled with tools that are laser-marked with the number of the machine to which they belong. Even better, each drawer contains a custom-milled, plastic organizer with individually machined pockets, each of which holds a specifically sized tool. The half-inch arbor will not fit in the 13-millimeter arbor pocket. If that half-inch arbor ends up at another machine, it can be identified by its laser marking.

A custom tool organizer can be found inside each Lista cabinet in FCG’s new setup kits located at every machining center.

“Learning is a big part of what we do,” Miller says. “This is all part of our mindset for setup reduction. We're getting the setup kits together. We're making the tooling readily available for the setup kits and setup techs. All the job-specific tooling is fitted for them. They just slap it in. That's part of how we can get to that two-hour setup time that I want to get to. And this all came out of the continuous improvement meetings.”

Out of the Lab

Forest City Gear has been using ECI JobBoss as its enterprise resource planning (ERP) software for several years, largely because of its customization features that align with FCG’s two-track, make-to-order and cut-teeth-only work. Now that the company knows exactly which machine will be designated for its quick-turnaround work, it uses the software’s scheduling feature for most of its parts. But conspicuous on the shop floor are also pieces of equipment that look decidedly low-tech, yet remain an important part of FCG’s overall process: giant whiteboards.

This is where you will find paper printouts that show everything from employee schedules to continuous improvement tallies (if your idea isn’t listed here, it probably means that it was rejected). At-a-glance information includes scrap rates, weekly and monthly metrics tracking setup efficiency, employee absences, machine tool oil level checks, average plant utilization, nonconformance events, safety records, on-time delivery rates, and production efficiencies.

Forest City Gear’s division manager, Mike Miller, is responsible for monitoring shopfloor trends such as setup efficiency and plant utilization.

These printouts are updated weekly, and it falls on the supervisors and department leads like Miller and Gates to notice any trends that might be moving in the wrong direction. Not unexpectedly , utilization rates plummeted during the onset of COVID-19. But once employees returned to work, this number took on a greater significance.

“If we see the daily machine PMs not getting checked or the number on my metric spiking, what was the reason for that?,” Miller asks. “Was somebody's gone for that couple of days? We're supposed to line the machine out if somebody's gone, and if somebody wasn't striking the machine out, who is the backup for that person? Was their backup gone? Who's the backup to my backup? It all falls back on me as the supervisor.”

Covid was (and still is, though to a lesser degree) a wildcard for some of these metrics, of course. If someone is calling in sick, is it because of low job satisfaction or a legitimate worry?

“Last year was a mess,” Gates says. “We kind of threw last year out the window when it came to a couple of these metrics. But that also gave us time to really focus in on other ideas that we’ve put in place recently.” The quality control department falls squarely under this category.

CNC department lead Josh P. Gates is responsible for implementing continuous improvement strategies for the turning and milling division at Forest City Gear.

As is the case for the production of highly complex gears, FCG sometimes takes on quality control work from other gear-making shops. Part of the reason is FCG’s adherence to owning and operating the latest equipment — the company uses a Zeiss Contura and a Zeiss Accurra II to handle some of its QC inspection — but it has also trained some of its employees to be “roving inspectors.” These employees are responsible for inspecting parts right at the machine after the initial first piece is complete. These in-process inspectors on the shop floor have helped reduce first-piece inspection time from an average of two or three hours down to 30 minutes.

“We have taken these guys out of the QC lab and put them out on the floor, with one person dedicated to each department,” Miller says. “And he's basically part of that department now — the inspector for that department. He's tied in and he knows what's going on inside that department. He can work with the setup guys. He's helping put the inspection tooling together, and he's working with all the department staff, and he knows directly what's going on at all times with regard to that setup. When they're ready for the first piece, he's on top of it.”

He’s on top of it — a fitting quote to sum up what, when taken individually, might seem like small, incremental steps. But put them together and they tell a different story.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreCreating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreJob Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreRead Next

An Introduction to Modern Machine Shop's Top Shops Program

Presented by Gardner Intelligence, an annual benchmarking program helps CNC machining businesses specifically evaluate and improve performance.

Read MoreTop Three Questions about the Top Shops Benchmarking Program

Our ninth annual Top Shops online benchmarking survey is now live. Here I answer three common questions I receive about it.

Read More