Workholding

Axial Forces Control Workholding System

Emuge’s System SG expanding-bush design workholding system is used in hobbing, shaping and shaving operations for gear production as well as in milling and inspection applications. The system’s design is based on a series of short tapers that expand or contract when acted upon by an axial force. The system can be designed for ID or OD clamping, allowing for expansion and contraction.

Read MoreStationary Clamping System

Schunk’s Tandem KSP plus stationary clamping system achieves a repeat accuracy of up to 0. 01 mm with the multi-tooth guidance of the base jaws, the long jaw guidance and the exact centering via the clamping sleeves which help reduce jaw lifting. The compact, clamping force block, which features a one-piece, rigid base body, achieves gripping forces ranging to 60kN.

Read More5-Axis Workholding System

Advanced Machine & Engineering announces the availability of the Triag 5axesClamp. According to the company, the spindle on a five-axis machine often has difficulty reaching all areas of a complex part using conventional workholding technology. The Triag workholding system minimizes interference, allowing machining spindles full access to workpieces, even in high-density applications.

Read MoreLow-Profile Rotary Table

The GD210LP low-profile rotary table from Hardinge is said to feature rigidity, speed, accuracy and repeatability. Large diameter bearings and a fail-safe clamping system provide high stiffness and high rigidity for parts weighing as much as 220 lbs. The table uses 233 foot-pounds (315 Nm) of clamping torque to handle off-center drilling, cross-axis milling and other high-force cutting applications.

Read MorePull Down Chuck

SMW Autoblok says its TX Pull-Down chuck features repeatability of up to 0. 0004″ (0. 01 mm) and is capable of operating under aggressive cutting conditions.

Read MoreMagnets Lift Flat, Round Materials

Eriez’s SafeHold XPL line of magnets can use one magnet to lift either flat or round materials. The magnets are available in six models with capacities ranging from 400 to 5,000 lbs for flat materials and 300 to 4,000 lbs for round materials. The small, lightweight magnets are constructed from Erium 3000 rare-earth, magnetic material, and they feature a powerful, magnetic force.

Read MoreCompact, High Speed Rotary Tables

Tsudakoma TN-101, TN-131, TN-161 and TN-201 compact, high speed, tilting rotary tables from Koma Precision use a dual taper, double-disc braking mechanism, which generates massive clamp torque—an increase of 320 percent when compared to previous models. The one-piece monoblock frame construction permits maximum rigidity. The tables feature an indexing and tilting repeatability of ±2 arcseconds and are available with a full range of options including rotary scales and various chucks and collets.

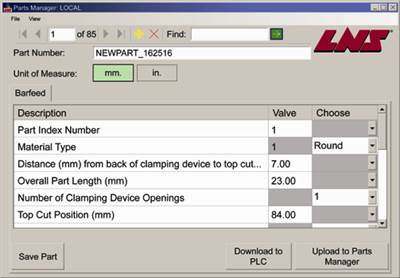

Read MoreLathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Read MoreAutomation Helps Move To High-Volume Production

This tool manufacturer had to automate its processes after switching from low-volume special orders to high-volume production runs. Since implementing Tsudakoma tilting rotary tables along with robotics and a pallet conveyor, the shop has increased sales by 400 percent.

Read MoreModular Fixturing System

The Demmeler modular fixturing system from Bluco features accurate five-sided welding tables made of high-tensile-strength steel. Angles, spacer blocks, clamps, positioning and clamping bolts and universal stops can be assembled into a ready-to-use welding fixture in a matter of hours, the company says. The system is said to be ideal for prototypes, spares and other short-run jobs, the company says.

Read More